75

As a minimum, the following maintenance is required.

1. At least once a year, disconnect the vent piping at the

valve outlet and carefully inspect the valve body and

mechanism for any evidence of internal corrosion or

rust, dirt, scale, leakage, etc.

2. If corrosion or foreign material is found, do not

attempt to repair or recondition. Replace the valve.

3. If the chiller is installed in a corrosive atmosphere or

the relief valves are vented into a corrosive

atmosphere, make valve inspections at more frequent

intervals.

Compressor Bearing Maintenance —

The key to

good bearing maintenance is proper lubrication. Use the proper

grade of oil, maintained at recommended level, temperature,

and pressure. Inspect the lubrication system regularly and

thoroughly.

Excessive bearing wear can be detected through increased

vibration. If this symptom appears, contact an experienced and

responsible service organization to perform vibration analysis

on the compressor.

Compressor Rotor Check —

Use Carrier specified

oil. Excessive compressor rotor wear is shown by a lack of per-

formance. If a lack of performance is noted, have the compres-

sor rotors inspected by a trained service person.

The rotors can be visually inspected once every 5 to

10 years or as needed depending on chiller operating

conditions.

Inspect the Heat Exchanger Tubes

COOLER — Inspect and clean the cooler tubes at the end of

the first operating season. Because these tubes have internal

ridges, a rotary-type tube cleaning system is necessary to fully

clean the tubes. Upon inspection, the tube condition will deter-

mine the scheduled frequency for cleaning, and will indicate

whether water treatment is adequate in the chilled water/

brine circuit. Inspect the entering and leaving chilled water

temperature sensors for signs of corrosion or scale. Replace the

sensor if corroded or remove any scale if found.

CONDENSER — Since this water circuit is usually an open-

type system, the tubes may be subject to contamination and

scale. Clean the condenser tubes with a rotary tube cleaning

system at least once per year and more often if the water is con-

taminated. Inspect the entering and leaving condenser water

sensors for signs of corrosion or scale. Replace the sensor if

corroded or remove any scale if found.

Higher than normal condenser pressures, together with the

inability to reach full refrigeration load, usually indicate dirty

tubes or air in the chiller. If the refrigeration log indicates a rise

above normal condenser pressures, check the condenser refrig-

erant temperature against the leaving condenser water tempera-

ture. If this reading is more than what the design difference is

supposed to be, then the condenser tubes may be dirty or water

flow may be incorrect. Because HCFC-22 and HFC-134a are

high-pressure refrigerants, air usually does not enter the chiller;

instead the refrigerant leaks out.

During the tube cleaning process, use brushes especially de-

signed to avoid scraping and scratching the tube wall. Contact

your Carrier representative to obtain these brushes. Do not use

wire brushes.

Water Leaks —

Water is indicated during chiller opera-

tion by the refrigerant moisture indicator on the refrigerant mo-

tor cooling line. See Fig. 11 and 12. Water leaks should be re-

paired immediately.

Water Treatment —

Untreated or improperly treated wa-

ter may result in corrosion, scaling, erosion, or algae. The ser-

vices of a qualified water treatment specialist should be ob-

tained to develop and monitor a treatment program.

Inspect the Starting Equipment —

Before working

on any starter, shut off the chiller, and open all disconnects sup-

plying power to the starter.

Hard scale may require chemical treatment for its preven-

tion or removal. Consult a water treatment specialist for

proper treatment.

Chiller must be dehydrated after repair of water leaks. See

Chiller Dehydration section, page 58.

Water must be within design flow limits, clean, and treated

to ensure proper chiller performance and to reduce the

potential of tubing damage due to corrosion, scaling, ero-

sion, and algae. Carrier assumes no responsibility for

chiller damage resulting from untreated or improperly

treated water.

The disconnect on the starter front panel does not deener-

gize all internal circuits. Open all internal and remote dis-

connects before servicing the starter.

Never open isolating knife switches while equipment is

operating. Electrical arcing can cause serious injury.

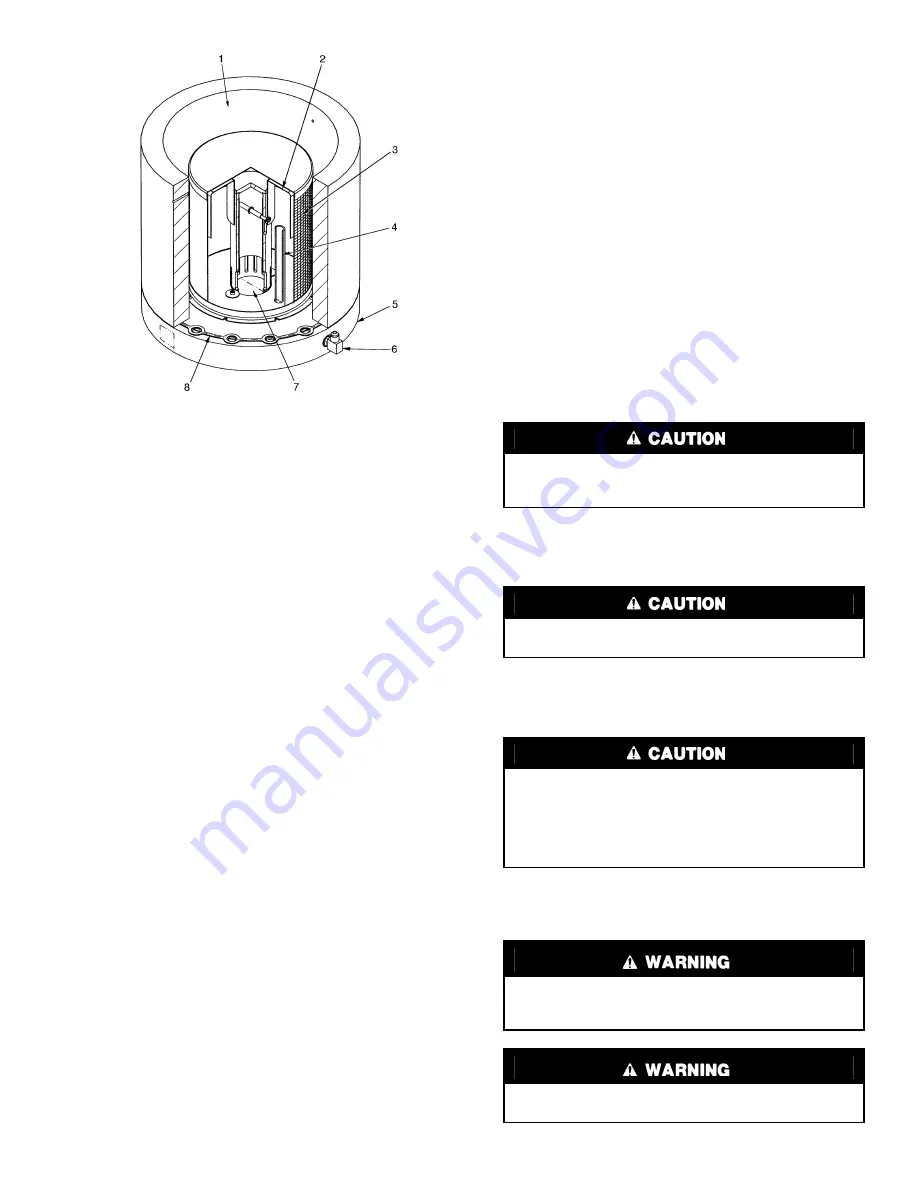

LEGEND

Fig. 40 — 23XL Float Valve Design

1

— Refrigerant Inlet from FLASC Chamber

2

— Linear Float Assembly

3

— Float Screen

4

— Bubble Line

5

— Float Cover

6

— Bubble Line Connection

7

— Refrigerant Outlet to Cooler

8

— Gasket

Содержание 23XL

Страница 18: ...18 Fig 15 Control Panel Fig 16 Power Panel ...

Страница 51: ...51 Fig 31 23XL Leak Test Procedure ...

Страница 52: ...52 Fig 32 Typical Optional Pumpout System Piping Schematic with Storage Tank TC Frame 1 and 2 Chillers ...

Страница 53: ...53 Fig 33 Typical Optional Pumpout System Piping Schematic With Storage Tank TD Frame 4 Chillers ...

Страница 54: ...54 Fig 34 Typical Optional Pumpout System Piping Schematic Without Storage Tank TC Frame 1 and 2 Chillers ...

Страница 55: ...55 Fig 35 Typical Optional Pumpout System Piping Schematic Without Storage Tank TD Frame 4 Chillers ...

Страница 99: ...99 Fig 49 Benshaw Inc Solid State Unit Mounted Starter Wiring Schematic Low Voltage ...