6-31

T-294-01

6.28 WATER-COOLED CONDENSER

The water-cooled condenser is of the shell and coil type

with water circulating through the cupro-nickel coil.

The refrigerant vapor is admitted to the shell side and is

condensed on the outer surface of the coil.

Rust, scale and slime on the water-cooling surfaces

inside of the coil interfere with the transfer of heat,

reduce system capacity, cause higher head pressures

and increase the load on the system.

If the water-cooled condenser is dirty, it may be cleaned

and de-scaled by the following procedure:

a. Turn unit off and disconnect main power.

b. Disconnect water pressure switch tubing by

loosening the two flare nuts. Install one-quarter

inch flare cap on water-cooled condenser inlet tube

(replaces tubing flare nut). De-scale tubing if

necessary.

What You Will Need:

1. Oakite composition No. 22, available as a powder

in 68 kg (150 lb) and 136 kg (300 lb).

2. Oakite composition No. 32, available as a liquid in

cases, each containing 3.785 liters (4 U.S. gallon)

bottles and also in carboys of 52.6 kg (116 lbs) net.

3. Fresh clean water.

4. Acid proof pump and containers or bottles with

rubber hose.

NOTE

When Oakite compound No. 32 is being used

for the first time, the local Oakite Technical

Service representative should be called in for

their suggestions in planning the procedure.

They will show you how to do the work with a

minimum dismantling of equipment: how to

estimate the time and amount of compound

required; how to prepare the solution; how to

control and conclude the de-scaling operation

by rinsing and neutralizing equipment before

putting it back into service. Their knowledge of

metals, types of scale, water conditions and

de-scaling techniques will be highly useful to

you.

Summary of Procedure:

a. Drain water from condenser tubing circuit. Clean

water tubes with Oakite No. 22 to remove mud and

slime.

b. Flush.

c. De-scale water tubes with Oakite No. 32 to remove

scale.

d. Flush.

e. Neutralize.

f. Flush.

g. Put unit back in service under normal load and

check head (discharge) pressure.

Detailed Procedure:

1. Drain and flush the water circuit of the condenser

coil. If scale on the tube inner surfaces is

accompanied by slime, a thorough cleaning is

necessary before de-scaling process can be

accomplished.

2. To remove slime or mud, use Oakite composition

No. 22. Mixed 170 grams (6 ounces) per 3.785 liters

(1 U.S. gallon) of water. Warm this solution and

circulate through the tubes until all slime and mud

has been removed.

3. After cleaning, flush tubes thoroughly with fresh

clean water.

4. Prepare a 15% by volume solution for de-scaling,

by diluting Oakite compound No. 32 with water.

This is accomplished by slowly adding 0.47 liter (1

U.S. pint) of the acid (Oakite No. 32) to 2.8 liters (3

U.S. quarts) of water.

WARNING

Oakite No. 32 is an acid --be sure that the

acid is slowly added to the water. DO NOT

PUT WATER INTO THE ACID! -- this will

cause spattering and excessive heat.

Wear rubber gloves and wash the solution

from the skin immediately if accidental

contact occurs. Do not allow the solution to

splash onto concrete.

5. Fill the tubes with this solution by filling from the

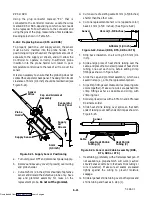

bottom. See Figure 6-33. Important: be sure to

provide a vent at the top for escaping gas.

Downloaded from

Содержание 69NT40-511-200

Страница 63: ...4 3 T 294 01 Page is left intentionally blank Downloaded from ManualsNet com search engine ...

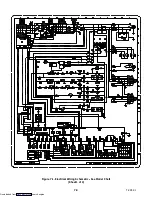

Страница 117: ...7 2 T 294 01 Figure 7 1 Electrical Schematic See Model Chart Sheet 1 of 2 Downloaded from ManualsNet com search engine ...

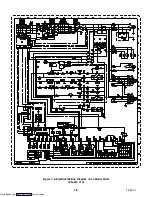

Страница 119: ...7 4 T 294 01 Figure 7 2 Electrical Schematic See Model Chart Sheet 1 of 2 Downloaded from ManualsNet com search engine ...