ENG

“Power+” +0300050EN - rel. 2.3 - 08.06.2012

11

Note

: the control signals terminal unit 1...8 and the relay terminals unit

9, 10 are double isolated from each other and with respect to the power

terminal board.

Important

:

•

in the European Union, all units that incorporate the drive must comply

with the Machinery Directive 2006/42/EC. Specifi cally, the manufacturer

of the unit is responsible for the installation of a main switch and the

conformity to standard EN 60204-1;

•

for fi xed installations according to IEC61800-5-1, a disconnect device is

required on the circuit between the power supply and the drive;

•

only use permanently wired power input connections; the drive must be

earthed: the earth wire must be sized for the maximum fault current that is

normally limited by the fuses or a circuit breaker.

3.7 Conformity to EMC standards

Power+ is designed in compliance with the high EMC standards. All models

are supplied with an internal EMC fi lter, designed to reduce the emissions

taken towards the power supply line in conformity with harmonised European

Standards. It is the installer’s responsibility that the device or system within

which Power+ is incorporated is in compliance with the Standards in force

in the country of use. The Standard in force within the European Union is the

EMC 2004/108/EC Directive. Power+ is intended to be incorporated inside

fi xed installation devices, only installed by specialised staff .

Conformity with the EMC Standard means that the indications given in the

“Electric connections” paragraph are respected and, as it also depends on

wiring topology, it must be checked on the fi nal machine as envisioned by

the Final Product Standard.

3.8 Electrical

connections

For installation proceed as shown below, with reference to the general

connection diagram (par. 3.10).

Important

:

the following warnings must be observed when connecting the drive:

•

separate as much as possible the probe and digital input cables (at least 40

cm) from the power cables to avoid possible electromagnetic disturbance.

Never lay power cables (including the electrical panel cables) and probe

signal cables in the same conduits;

•

the cables must be sized according to the table in paragraph 9.1;

•

when the fuses are used, these must be chosen according to the data

shown in the table in paragraph 9.1, and must comply with the national

and local standards in force. In general, use type gG fuses for IEC and type

T for UL, with a blow time less than 0.5 s;

•

when a magnetic circuit breaker (MCB) is used, it must be of type B, rated

according to the data shown in the table in paragraph 9.1;

•

avoid installing cables connected to the control terminal block in the

immediate vicinity of power devices (contactors, circuit breakers, etc.).

Reduce the path of the cables as much as possible, and avoid spiral paths

that enclose power devices.

Use cables rated to 90 °C, and if the temperature of the terminals exceeds 85

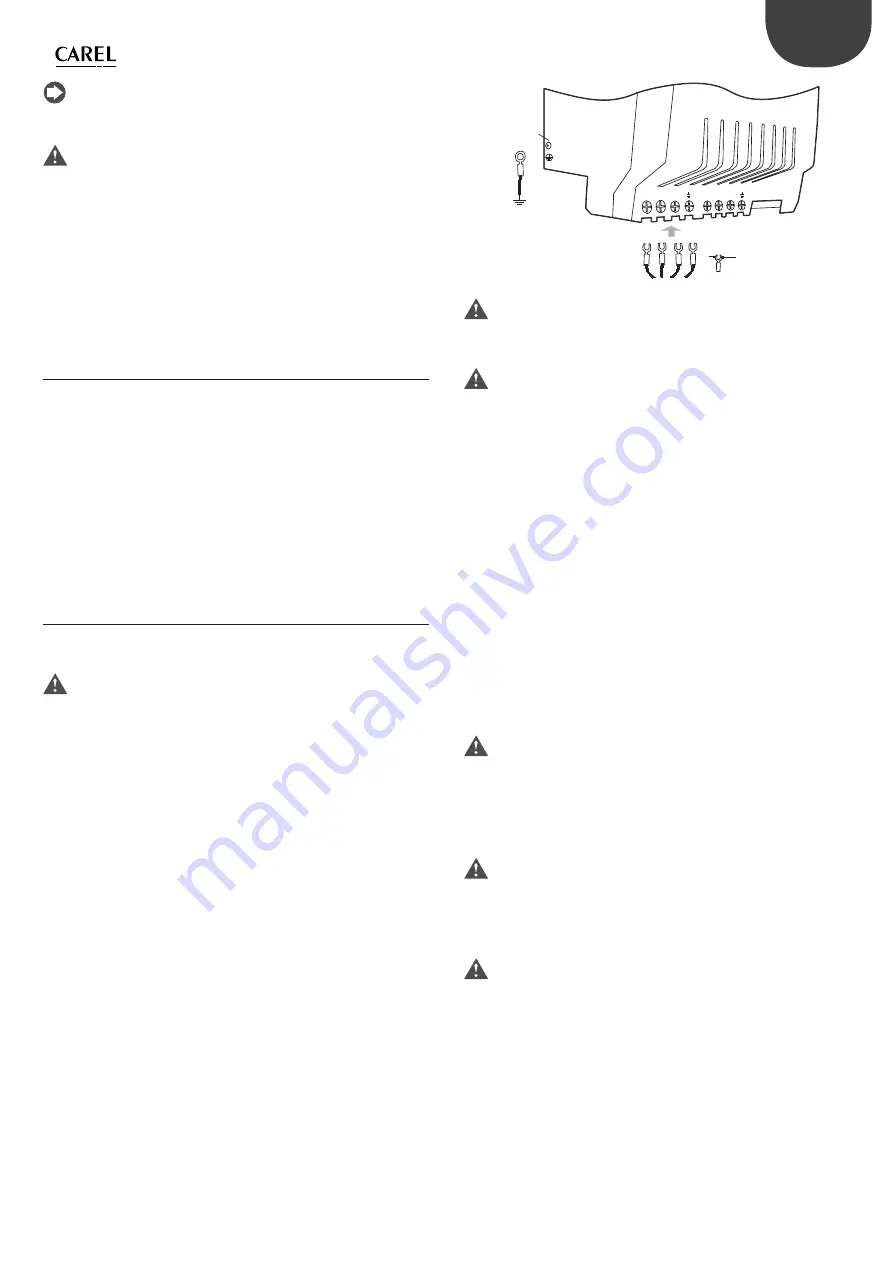

°C, use cables rated to 105 °C. Use cable terminals suitable for the terminals

and the cables used. Loosen each screw and insert the cable ends, then

tighten the screws and lightly tug the cables to check correct tightness. For

fork cable terminals, do not exceed the maximum width shown in the fi gure.

L1/L L2/N L3

U

V

W

Vite / screw

M4

7,5 mm MAX

Fig. 3.h

Important

: the tightening torque is:

•

power terminals: 1 Nm;

•

control terminals: 0,5 Nm.

Important:

In the unscrewing phase, do not force the screw further when it is fully

home.

The drive must be earthed: to do this, use either the screw terminal (earth

symbol ), or the screw (PE symbol ) on the side of the heat sink, in accordance

with local standards in force. To minimise EMC problems, use a power cable

with earth wire included, connected to terminal . The power supply earth

must be connected directly to the earth bar in the electrical panel, without

branches to other devices; the earth wire size must be greater than or equal

to the phase wires; the earth impedance must be compliant with national

and local standards; in compliance with UL requirements, the protective

earth connections (PE) must be made using eyelet lugs. On single-phase

models, also connect the PFC coil. On three-phase models, where necessary

connect the optional DC choke in place of the jumper that closes terminals

C1 and C2. See the “Terminals C1 and C2” paragraph.

P

ower supply

Connect the power cables: for single-phase models connect the power

supply to terminals L1/L and L2/N, for three-phase models to terminals L1, L2,

L3; for the size of the cables and the type of fuses, see the table in paragraph

9.1.

Important

:

•

do not connect the power supply to terminals U, V, W;

•

make sure the voltage, frequency and number of phases in the power

supply match the ratings of the specifi c model.

Terminals

C1

and

C2

Important:

The use of terminals C1 and C2 depends on the model and diff ers based on

the type of power supply: single-phase or three-phase.

Models with 200/240 Vac single-phase power supply

Connect the PFC coil supplied with the drive to terminals C1 and C2.

Important

:

Never short-circuit terminals C1 and C2.

The PFC coil does not require connection to earth.

See paragraph 3.12 for dimensions of the PFC coil.

Содержание Power+

Страница 2: ......

Страница 4: ......

Страница 6: ...ENG Power 0300050EN rel 2 3 08 06 2012 6 ...

Страница 35: ......