41

ENG

“EVD evolution” +030222041 - rel. 1.0 - 01.06.2008

TROUBLEShOOTING

10.

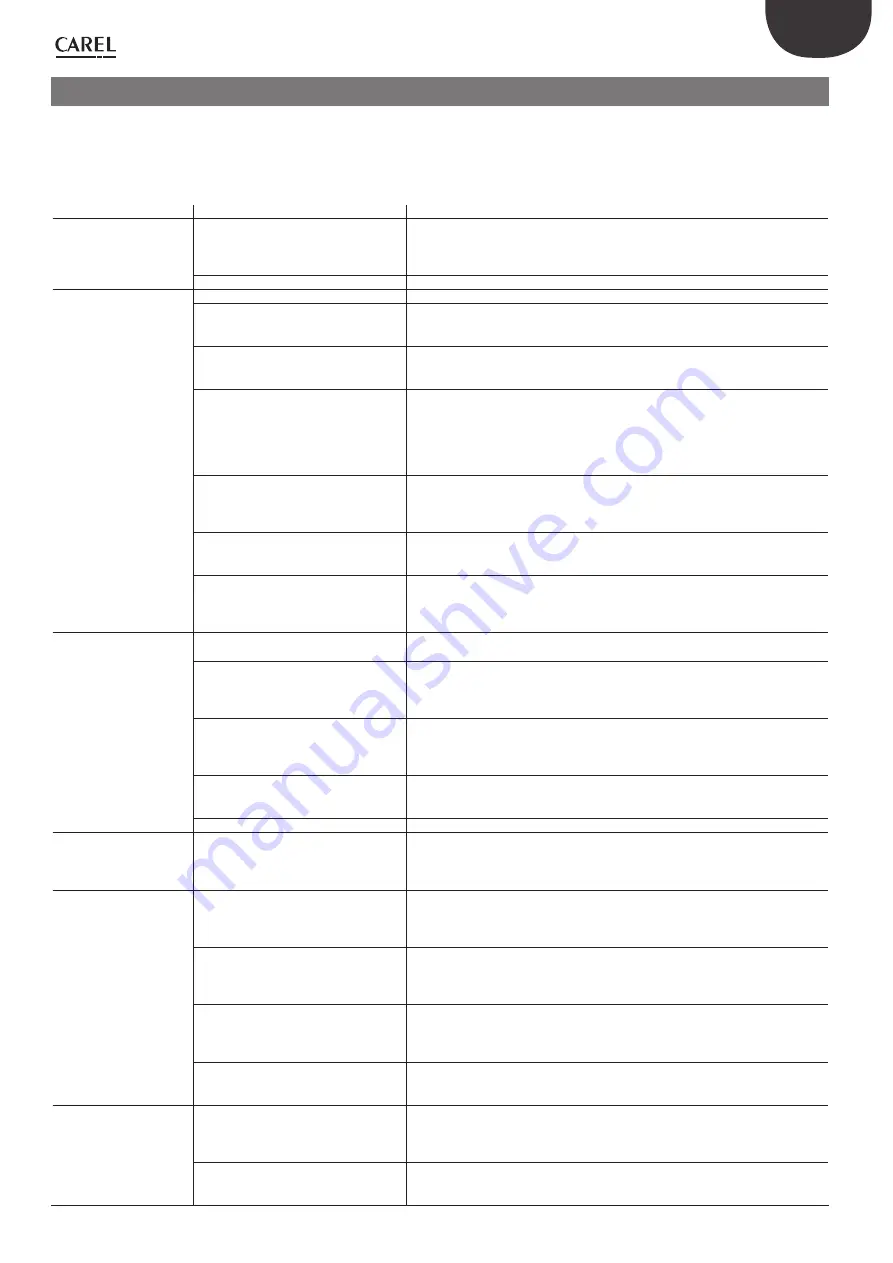

The following table lists a series of possible malfunctions that may occur

when starting and operating the driver and the electronic valve. These

cover the most common problems and are provided with the aim of

offering an initial response for resolving the problem.

PROBLEM

CAUSE

SOLUTION

The superheat value measu-

red is incorrect

The probe does not measure correct values Check that the pressure and the temperature measured are correct and that the probe

position is correct. Check that the minimum and maximum pressure parameters for the

pressure transducer set on the driver correspond to the range of the pressure probe

installed. Check the correct probe electrical connections.

The type of refrigerant set is incorrect

Check and correct the type of refrigerant parameter.

Liquid returns to the com-

pressor during control

The type of valve set is incorrect

Check and correct the type of valve parameter.

The valve is connected incorrectly (rotates

in reverse) and is open

Check the movement of the valve by placing it in manual control and closing or ope-

ning it completely. One complete opening must bring a decrease in the superheat and

vice-versa. If the movement is reversed, check the electrical connections.

The superheat set point is too low

Increase the superheat set point. Initially set it to 12 °C and check that there is no

longer return of liquid. Then gradually reduce the set point, always making sure there is

no return of liquid.

Low superheat protection ineffective

If the superheat remains low for too long with the valve that is slow to close, increase

the low superheat threshold and/or decrease the low superheat integration time.

Initially set the threshold 3 °C below the superheat set point, with an integration time

of 3-4 seconds. Then gradually lower the low superheat threshold and increase the low

superheat integration time, checking that there is no return of liquid in any operating

conditions.

Stator broken or connected incorrectly

Disconnect the stator from the valve and the cable and measure the resistance of the

windings using an ordinary tester.

The resistance of both should be around 36 ohms. Otherwise replace the stator. Finally,

check the electrical connections of the cable to the driver.

Valve stuck open

Check if the superheating is always low (<2 °C) with the valve position permanently at

0 steps. If so, set the valve to manual control and close it completely. If the superheat is

always low, check the electrical connections and/or replace the valve.

The “valve opening at start” parameter

is too high on many cabinets in which

the control set point is often reached (for

multiplexed cabinets only)

Decrease the value of the “Valve opening at start” parameter on all the utilities, making

sure that there are no repercussions on the control temperature.

Liquid returns to the com-

pressor only after defrosting

(for multiplexed cabinets

only)

The pause in control after defrosting is too

short

Increase the value of the “valve control delay after defrosting” parameter.

The superheat temperature measured

by the driver after defrosting and before

reaching operating conditions is very low

for a few minutes

Check that the LowSH threshold is greater than the superheat value measured and that

the corresponding protection is activated (integration time >0 s). If necessary, decrease

the value of the integration time.

The superheat temperature measured by

the driver does not reach low values, but

there is still return of liquid to the compres-

sor rack

Set more reactive parameters to bring forward the closing of the valve: increase the

proportional factor to 30, increase the integration time to 250 s and increase the deri-

vative time to 10 sec.

Many cabinets defrosting at the same time Stagger the start defrost times. If this is not possible, if the conditions in the previous

two points are not present, increase the superheat set point and the LowSH thresholds

by at least 2 °C on the cabinets involved.

The valve is significantly oversized

Replace the valve with a smaller equivalent.

Liquid returns to the com-

pressor only when starting

the controller (after being

OFF)

The “valve opening at start” parameter is

set too high

Check the calculation in reference to the ratio between the rated cooling capacity of

the evaporator and the capacity of the valve; if necessary, lower the value.

The superheat value swings

around the set point with an

amplitude greater than 4°C

The condensing pressure swings

Check the controller condenser settings, giving the parameters “blander” values (e.g.

increase the proportional band or increase the integration time). Note: the required sta-

bility involves a variation /- 0.5 bars. If this is not effective or the settings cannot

be changed, adopt electronic valve control parameters for perturbed systems

The superheat swings even with the valve

set in manual control (in the position cor-

responding to the average of the working

values)

Check for the causes of the swings (e.g. low refrigerant charge) and resolve where pos-

sible. If not possible, adopt electronic valve control parameters for perturbed systems.

The superheat does NOT swing with the

valve set in manual control (in the position

corresponding to the average of the

working values)

As a first approach , decrease (by 30 to 50 %) the proportional factor. Subsequently try

increasing the integration time by the same percentage. In any case, adopt parameter

settings recommended for stable systems.

The superheat set point is too low

Increase the superheat set point and check that the swings are reduced or disappear.

Initially set 13 °C, then gradually reduce the set point, making sure the system does not

start swinging again and that the unit temperature reaches the control set point.

In the start-up phase with

high evaporator tempe-

ratures, the evaporation

pressure is high

MOP protection disabled or ineffective

Activate the MOP protection by setting the threshold to the required saturated eva-

poration temperature (high evaporation temperature limit for the compressors) and

setting the MOP integration time to a value above 0 (recommended 4 seconds). To

make the protection more reactive, decrease the MOP integration time.

Refrigerant charge excessive for the system

or extreme transitory conditions at start-up

(for cabinets only).

Apply a “soft start” technique, activating the utilities one at a time or in small groups. If

this is not possible, decrease the values of the MOP thresholds on all the utilities.