6

0

4

3

2

1

5

6

100

200

800

700

600

500

400

300

900

1000

1100

l/h

mCE

Débit mini (robinets thermostatiques fermés)

Hauteur manométrique

GVF

GV

O

PVF

PV

O

20

40

60

80

100

120

Pf

140

160

180

200

220

240

0,7

0,8

0,9

1,0

1,1

1,2

1,3

1,4

1,5

1,6

1,7

1,8

1,9

2,0

Capacité maximale de l'installation (en litres)

80

°

C

70

°

C

60

°

C

50

°

C

40

°

C

260

Pression à froid pour le circuit chauffage (en bar)

C liter

2

3

Fig. 5

Fig. 6

440

450 mini pour entretien

With packaging

:

24

43 kg

30

45,5 kg

108 108

JL

N

I

88

J

L

N

232

235

32

380

212

360

50

67

850

737

Safety valve

center line

All dimensions in mm

Fig. 4

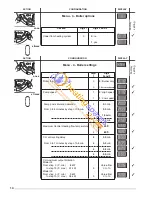

Pump head chart available at the outlet of the boiler

System capacity chart

The boiler comprises a double speed pump and an

adjustable by-pass.

The chart (fig. 5) shows the pump head available regarding

the flow rate. GVF means high speed by-pass closed, PVF

means low speed by-pass closed, GVO means high speed

by-pass fully open, PVO means low speed by-pass fully

open.

For adjustment procedure, please refer to § 8.

The minimum flow rate to insure a correct functioning of the

should be over 300 l/h (with thermostatic valves fully

closed)

Maximum water capacity of Central Heating system :

The expansion vessel is pre-charged to 0.7 bar (10 lb/in 2 ).

The vessel is suitable for systems up to 145 litres capacity.

For systems of greater capacity an additional expansion

vessel will be required. Refer to the chart below and BS

7074 pt 1 or BS 5449.

The minimum initial pressure of the system should be over

0.7 bar (1 to 1.5 bar is recommended).

I

Safety valve C/H and condensate

J

Heating flow

L

Gas supply

N

Heating return

minimum space required 450

Pump head available

Minimum flow rate (with all heating thermostatic valves closed)

Central heating initial pressure when cold (in bar)

Outer case dimensions :

- Width :

440 (minimum space required 450)

- Height :

850

- Depth :

380 (24kW) - 405 (30 kW)

Minimum clearances :

- Both sides

5 mm

- Above casing

170 mm

- Below casing

200 mm

- Front ( for servicing) 500 mm

- Front (in operation)

5 mm

Ø 100

Type C 12

206

143

Ø 125

Ø 80

120

Ø 80

Type C 32 xx

Type C 32 xy

250

Ø 80

250

Ø 100

Type C 12

206

143

Ø 125

Ø 80

120

Ø 80

Type C 32 xx

Type C 32 xy

250

Ø 80

250

Type C 13

Type C 33

Ø 100

Type C 12

206

143

Ø 125

Ø 80

120

Ø 80

Type C 32 xx

Type C 32 xy

250

Ø 80

250

Type C 53

The boiler is suitable

for the flue types:

• type C 13

• type C 33

• type C 53

170

225

24 : 380

30 : 405

Dimensions

Hydraulic Data