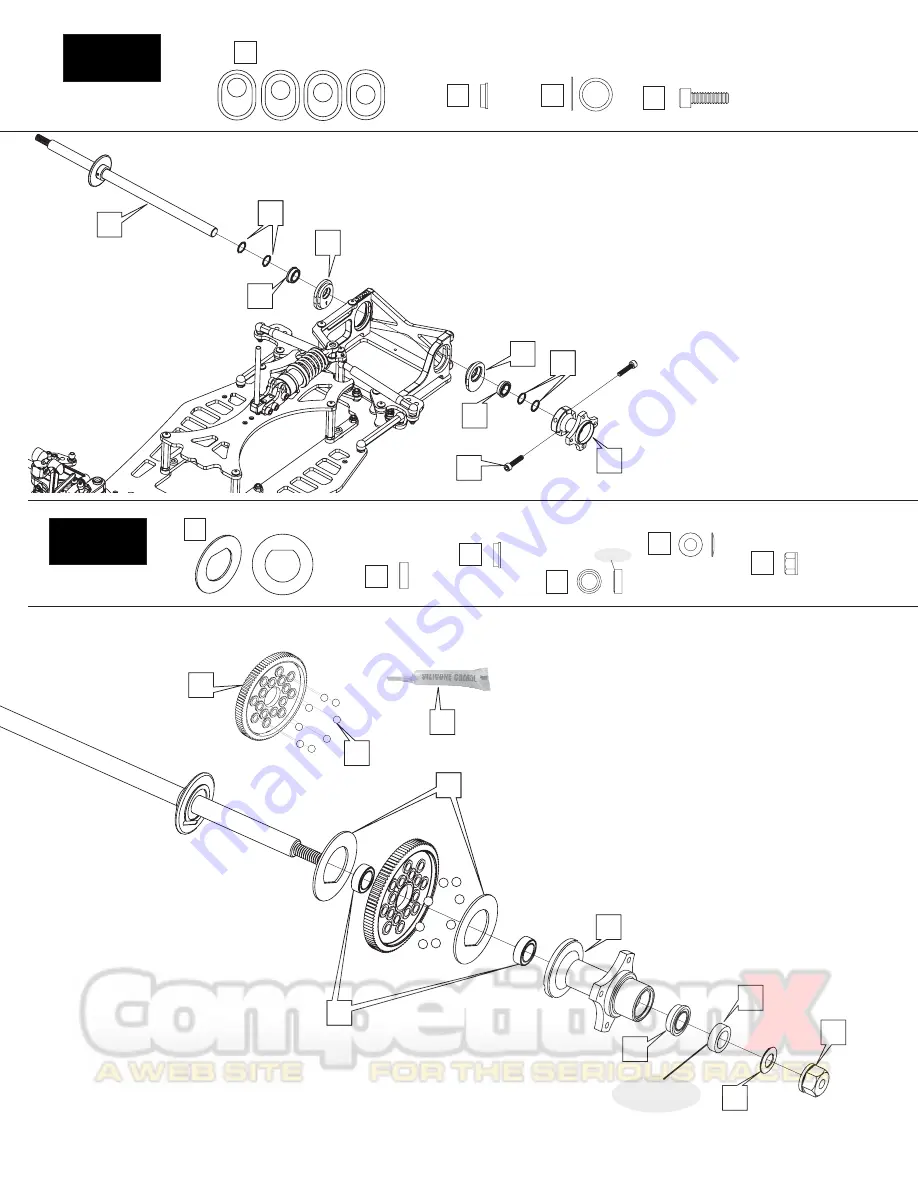

Diff Ring

Bag 9

Differential

1/4” x 3/8”

Flanged Bearing

82

90

1/4” x 3/8”

Plain Bearing

91

Lip

Diff Spacer

93

Spring Washer

94

Nylon Diff Nut

95

6 - Lock the hub in place with the two 4-40 x 3/8” steel cap head screws [86] so

that the axle has a very small amount of side to side play in it. The thickness

Bag 8

1 - Locate the tree of ride height inserts [81]. Select an insert that will work best with your

tire size

. Save the

left over inserts as you will use these to adjust rear ride height as the tires wear.

2 - Insert a 1/4” x 3/8” [82] Flanged Bearing into each of the ride height spacers.

3 - Now insert the ride height spacers into the rear pod plates with the bearings up.

4 - Slide the rear axle [83] through two 1/4” shims [84] and into the 2 rear pod bearings.

5 - On the protruding axle, slip two more 1/4” shims over the axle. Then slip the hub [85] on

as shown in the picture.

(example - the #2 spacers will give you about 5mm of ride height with 2.20” tires)

Differential Axle

1/4” Shim

1 - I

NSTALL AND GREASE THE DIFF BALLS

Pop the 1/8” diff balls [87] into each of the outer ring of holes in the

diff gear [88]. The balls snap into the socket. Place a small dab of

silicone diff grease [89] on each ball. Use very little!

*(Holding the car on it’s side, with the rear axle pointing upright will

ease assembly of the diff.) Place 1 diff ring [90], and then a 1/4” x

3/8” plain bearing [91] over the end of the axle. Align the diff ring so

that it notches into the axle flange. Place the assembled gear with

the greased diff balls over the axle and push it down over the plain

bearing. Next, insert the other plain bearing into the back of the diff

hub [92]. Then, align the second diff ring with the notch on the back

of the diff hub. *(place a small dab of the diff grease on the hub first

to hold the ring in place.)* Now, slide the hub, bearing, & diff ring

down over the axle. Next, slide a flanged bearing [82] over the axle

and into the front of the diff hub.

2 - D

IFF

A

SSEMBLY

Small lip

toward bearing

1

** Balls in outer ring of holes in gear **

81

83

1/4” x 3/8”

Flanged Bearing

Ride Height Inserts

82

84

82

81

81

84

85

86

82

D

IFF

A

SSEMBLY

-

CONTINUED

...

The diff spacer [93] has a small machined

lip on one side, point that lip toward the

bearing. Now, place the spring washer [94]

so that the cone points away from the gear.

The outside of the washer should be

against the diff spacer, and the inside of the

washer should be against the diff nut [95],

which now goes on last. *Be sure the 2 “D”

rings have settled into their notches. Just

snug the nut so the parts stay together on

the diff axle. Correct diff tension needs to

be set with tires on the car. We will do this

later.

87

88

89

91

92

94

93

95

82

90

84

0

1

2

3

4-40 x 3/8”

Steel Socket Cap

86

of 2 sheets of paper is plenty. You don’t want

excessive play here, you’re just making sure

to not pinch the bearings.

14