7

This furnace is certified for use with a Type “L” vent

(maximum flue gas temperature 302°C (575°F)). The f lue

pipe clearance knockout in the front top or side panel should

be removed. Install the flue elbow so that it exits the furnace

cabinet through that opening.

Pre-installation vent system inspection

Before this furnace is installed, it is strongly recommended

that any existing vent system be completely inspected.

On any chimney or vent, this should include the following:

a. Inspection for any deterioration in the chimney or vent.

If deterioration is discovered, the chimney must be

repaired or the vent replaced;

b. Inspection to ascertain that the vent system is clear and

free of obstructions. Any blockages must be removed

before installing this furnace;

c.

Cleaning the chimney or vent if previously used for

venting a solid fuel burning appliance or fireplace;

d. Confirming that all unused chimney or vent connections

are properly sealed;

e. Verification that the chimney is properly lined and sized

per the applicable codes. (Please refer to list of codes

in Part 1.2)

Masonry Chimneys

This furnace may be vented into an existing masonry

chimney. However, it must not be vented into a chimney

servicing a solid fuel-burning appliance. Before venting this

furnace into a chimney, the chimney must be checked for

deterioration and repaired if necessary. The chimney must

be properly lined and sized per local and/or national codes.

The chimney must be of sufficient area to accommodate the

total flue products of all appliances vented into the chimney.

The following requirements are provided for a safe venting

system:

a. Ensure that the chimney flue is clear of any dirt or

debris;

b. Ensure that the chimney is not servicing an open

fireplace;

c.

Never reduce the pipe size below the outlet size of the

furnace;

d. All pipes should be supported, using the proper clamps

and/or straps. These supports should be installed at

least every 4 feet;

e. All horizontal runs of pipe should have at least 20 mm

of upward slope per 1 m (1/4” per 1');

f.

All runs of pipe should be as short as possible with as

few turns as possible;

g. Seams should be tightly joined and checked for leaks;

h. The flue pipe must not extend into the chimney but be

flush with the inside wall;

i.

The chimney must extend 0.9 m (3') above the highest

point where it passes through a roof of a building and at

least 0.6 m (2') higher than any portion of a building

within a horizontal distance of 3 m (10'). It shall also be

extended at least 1.5 m (5') above the highest

connected equipment flue collar;

j.

Check local codes for any variances.

Factory Built Chimneys

Approved factory built chimneys may be used. Refer to

chimney manufacturer’s instructions for proper installation.

2.4.4

Draft Regulator

The draft regulator supplied with the furnace must be used

for proper functioning. Installation instructions are included

with the control.

2.4.5

Blocked vent shut-off (BVSO)

For chimney venting

All oil furnaces installed in Canada must have a blocked

vent shut-off.

WARNING

It is imperative that this device be installed by a

qualified agency.

This device is designed to detect the insufficient evacuation

of combustion gases in the event of a vent blockage. In such

a case the thermal switch will shut down the oil burner. The

device will then need to be re-armed MANUALLY.

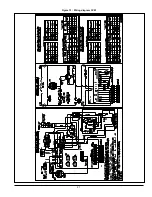

Please refer to Figures 2 to 8, the wiring diagrams, Figures

12 and 13, and the detailed instructions supplied with the

BVSO for the installation and wiring procedures. The length

of wires supplied with the unit is such that the safety device

must be installed between the flue outlet of the appliance

and the draft regulator, as indicated in the instructions.

Figure 2 : Wiring diagram,BVSO

For more details, refer to the instructions supplied with the

device itself, as well as section 3 of this manual.

DNS-01340 Rev A

Содержание CBMAAA060120

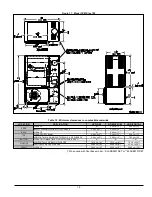

Страница 21: ...21 Figure 13 Wiring diagram CVM ...

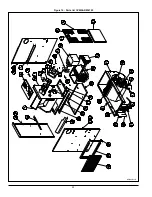

Страница 22: ...22 Figure 14 Parts list CVMAAR036105 B50003 Rev D ...

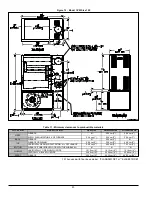

Страница 24: ...24 Figure 15 Parts list CVMAAR060120 B50004 Rev F ...

Страница 48: ...23 Figure 13 Diagramme électrique CVM ...

Страница 49: ...24 Figure 14 Liste de pièces CVMAAR036105 B50003 Rev D ...

Страница 51: ...26 Figure 15 Liste de pièces CVMAAR060120 B50004 Rev F ...