18

ELECTRICAL CONNECTIONS

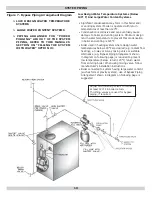

Thermostat

Install 24 Volt thermostat (not provided) in proper location.

Location of thermostat has effect on boiler system operation.

Follow instructions included with thermostat.

Grounding

Permanently ground boiler according to local codes and

latest revision of the National Electrical Code. Run 14

gauge or heavier copper wire from boiler to grounded

connection in service panel or properly driven and

electrically grounded ground rod.

Electric Power Supply

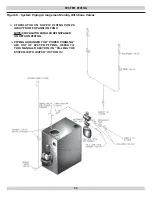

Installation must comply with the latest revision of the

National Electrical Code, any other national, state, or local

codes or regulations.

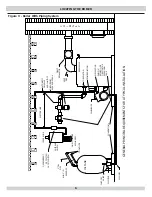

Connect 115 volt electrical supply to L1 and L2 terminals

on limit and two thermostat wires to T and T terminals on

same limit. See wiring diagram page 28.

Run separate circuit from separate over current protection

device in your electrical service entrance panel. Minimum

15 ampere circuit. Locate shutoff switch at boiler. Turn off

during any maintenance. Solder and tape or securely fasten

connections with wire nuts.

Oil Burner Wiring

For boilers packaged with oil burners, burners are wired

at the factory. For boilers shipped without a burner, wiring

connections are shown in the electrical wiring diagrams of

this manual.

WARNING

Electrical shock hazard. Turn OFF electrical power supply

at service panel before making electrical connections.

Failure to do so could result in death or serious injury.

!

Содержание BW4BAH-91

Страница 22: ...22 OPERATING THE BOILER Figure 13 Burner Adjustments and Settings...

Страница 28: ...28 ELECTRICAL WIRING Figure 16 Honeywell L7248L Control With Beckett AFG Burner...

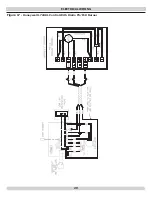

Страница 29: ...29 Figure 17 Honeywell L7248L Control With Riello F5 F10 Burner ELECTRICAL WIRING...

Страница 31: ...NOTES...

Страница 32: ...CAC BDP 7310 West Morris St Indianapolis IN 46231...