73

X. Service Instructions

A.

General.

Inspection and service should be conducted

annually, except as noted. Turn off electrical power and

gas supply while conducting service or maintenance.

Follow instructions TO TURN OFF GAS TO

APPLIANCE. See Figures 53, 54, 55, 56 or 57.

B.

Maintenance of Low Water Cutoff

1. McDonnell & Miller PS-802 or Hydrolevel

CycleGard CG400 Probe Style Only.

a. Drain boiler to point below Tapping 'K'. See

Figure 2.

b. Disconnect wire(s) connecting control and probe.

c. Remove control from probe.

R

E

G

N

A

D

e

r

u

s

s

e

r

p

o

r

e

z

t

a

s

i

r

e

li

o

b

e

h

t

t

a

h

t

e

r

u

s

s

A

t

o

n

o

D

.

e

b

o

r

p

O

C

W

L

e

h

t

g

n

i

v

o

m

e

r

e

r

o

f

e

b

t

a

h

t

e

t

a

c

i

d

n

i

o

t

e

g

u

a

g

e

r

u

s

s

e

r

p

e

h

t

n

o

y

l

e

r

e

h

t

n

e

p

O

.

e

r

u

s

s

e

r

p

o

r

e

z

t

a

s

i

r

e

li

o

b

e

h

t

e

r

u

s

s

e

r

p

l

a

n

r

e

t

n

i

ll

a

e

v

e

il

e

r

o

t

e

v

l

a

v

y

t

e

f

a

s

e

g

r

a

h

c

s

i

d

e

v

l

a

v

y

t

e

f

a

S

.

g

n

i

d

e

e

c

o

r

p

o

t

r

o

i

r

p

l

a

i

t

n

e

t

o

p

e

h

t

t

a

h

t

h

c

u

s

d

e

p

i

p

e

b

t

s

u

m

g

n

i

p

i

p

.

d

e

t

a

n

i

m

il

e

s

i

s

n

r

u

b

r

o

f

d. Unscrew probe from Tapping 'K'. Inspect for

scale and sediment buildup.

e. Remove light deposits with damp cloth soaked

with vinegar.

f. Remove stubborn deposits using diluted

phosphoric acid (H

2

PO

4

) solution, 3 parts water

to 1 part phosphoric acid. Normal operation will

occur with up to 0.2 inch of contamination. If

scale or contamination exceeds 0.2 inches, clean

probe more frequently.

g. Clean Tapping 'K' to remove old pipe dope and

other foreign matter.

h. Apply moderate amount of good quality pipe

dope to probe threads, leaving two end threads

bare. Install probe in Tapping 'K'. Mount control

on probe. Attach wire(s) between control and

probe.

i. Fill boiler to normal waterline. Add water

treatment as needed.

2. McDonnell & Miller 67 Float Style Only.

a. Weekly (or more frequently if necessary). Open

blow-off valve to flush sediment chamber.

Follow instructions on Blow-Down Card affixed

to Jacket adjacent to low water cutoff.

b. Annually. Dismantle to extent necessary to

remove obstructions and insure proper function

of working parts.

R

E

G

N

A

D

r

e

t

a

w

t

o

h

y

r

e

v

d

n

a

,

s

t

r

a

p

g

n

i

v

o

m

,

y

t

i

c

i

r

t

c

e

l

e

e

g

a

t

l

o

v

h

g

i

h

,

s

a

g

e

l

b

a

m

m

a

l

f

s

e

s

u

r

e

li

o

b

s

i

h

T

e

h

t

t

a

h

t

d

n

a

f

f

o

e

r

a

s

e

il

p

p

u

s

r

e

w

o

p

c

i

r

t

c

e

l

e

d

n

a

s

a

g

ll

a

t

a

h

t

e

r

u

s

s

A

.

e

r

u

s

s

e

r

p

h

g

i

h

r

e

d

n

u

.

e

c

i

v

r

e

s

r

o

y

l

b

m

e

s

s

a

s

i

d

y

n

a

g

n

i

t

p

m

e

t

t

a

e

r

o

f

e

b

l

o

o

c

s

i

e

r

u

t

a

r

e

p

m

e

t

r

e

t

a

w

y

n

a

g

n

i

t

p

m

e

t

t

a

e

r

o

f

e

b

f

f

o

e

r

a

s

e

h

c

t

i

w

s

t

c

e

n

n

o

c

s

i

d

l

a

c

i

r

t

c

e

l

e

d

n

a

s

e

v

l

a

v

s

a

g

ll

a

t

a

h

t

e

r

u

s

s

A

.

e

c

i

v

r

e

s

r

o

y

l

b

m

e

s

s

a

s

i

d

.

r

e

li

o

b

e

h

t

f

o

y

t

i

n

i

c

i

v

e

h

t

n

i

r

i

a

e

h

t

n

i

t

n

e

s

e

r

p

s

i

s

a

g

f

i

k

r

o

w

e

c

i

v

r

e

s

y

n

a

t

p

m

e

t

t

a

t

o

n

o

D

.

e

c

i

v

e

d

l

o

r

t

n

o

c

y

n

a

h

t

i

w

r

e

p

m

a

t

r

o

e

v

o

m

e

r

,

y

f

i

d

o

m

r

e

v

e

N

G

N

I

N

R

A

W

e

c

i

v

r

e

s

d

e

c

n

e

i

r

e

p

x

e

d

n

a

d

e

ll

i

k

s

y

b

d

e

r

i

a

p

e

r

d

n

a

d

e

c

i

v

r

e

s

e

b

y

l

n

o

t

s

u

m

r

e

li

o

b

s

i

h

T

.

s

n

a

i

c

i

n

h

c

e

t

.

s

l

e

d

o

m

l

a

c

i

t

n

e

d

i

h

t

i

w

e

b

t

s

u

m

y

e

h

t

,

d

e

c

a

l

p

e

r

e

r

a

s

l

o

r

t

n

o

c

y

n

a

f

I

s

n

o

i

t

c

e

s

e

h

t

ll

a

n

i

d

e

n

i

a

t

n

o

c

s

g

n

i

n

r

a

w

d

n

a

s

n

o

i

t

c

u

r

t

s

n

i

e

h

t

ll

a

w

o

ll

o

f

d

n

a

d

n

a

t

s

r

e

d

n

u

,

d

a

e

R

.l

a

u

n

a

m

s

i

h

t

f

o

e

r

u

s

s

a

d

n

a

s

e

r

i

w

e

h

t

l

e

b

a

l

y

l

r

a

e

l

c

,

e

c

i

v

r

e

s

g

n

i

r

u

d

d

e

t

c

e

n

n

o

c

s

i

d

e

r

a

s

e

r

i

w

l

a

c

i

r

t

c

e

l

e

y

n

a

f

I

.

y

l

r

e

p

o

r

p

d

e

t

c

e

n

n

o

c

e

r

e

r

a

s

e

r

i

w

e

h

t

t

a

h

t

.

r

e

li

o

b

s

i

h

t

f

o

t

n

e

n

o

p

m

o

c

r

o

l

o

r

t

n

o

c

g

n

i

t

a

r

e

p

o

r

o

y

t

e

f

a

s

y

n

a

s

s

a

p

y

b

r

o

t

u

o

p

m

u

j

r

e

v

e

N

e

h

t

f

o

L

L

A

n

i

d

e

n

i

a

t

n

o

c

s

g

n

i

n

r

a

w

d

n

a

s

n

o

i

t

c

u

r

t

s

n

i

e

h

t

ll

a

w

o

ll

o

f

d

n

a

d

n

a

t

s

r

e

d

n

u

,

d

a

e

R

.

s

l

a

u

n

a

m

n

o

i

t

c

u

r

t

s

n

i

t

n

e

n

o

p

m

o

c

e

r

o

f

e

b

y

l

r

e

p

o

r

p

g

n

i

t

a

r

e

p

o

e

r

a

s

t

n

e

n

o

p

m

o

c

d

n

a

s

l

o

r

t

n

o

c

g

n

i

t

a

r

e

p

o

d

n

a

y

t

e

f

a

s

ll

a

t

a

h

t

e

r

u

s

s

A

.

e

c

i

v

r

e

s

n

i

k

c

a

b

r

e

li

o

b

e

h

t

g

n

i

c

a

l

p

Содержание Independence

Страница 4: ... Figure 1 Dimensional Drawing ...

Страница 19: ...19 Figure 25 Recommended Water Piping for Circulator Zoned Heating System ...

Страница 20: ...20 Figure 25A Recommended Water Piping for Zone Valve Zoned Heating System ...

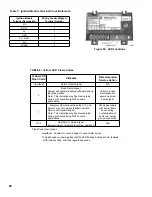

Страница 29: ...29 Figure 34 Vent Damper Schematic Wiring Diagram Figure 33 Vent Damper Harness to Limit ...

Страница 30: ...30 Figure 35 Wiring Diagrams Steam Continuous Ignition Standing Pilot Probe Low Water Cutoff ...

Страница 32: ...32 Figure 36 Wiring Diagrams Steam Intermittent Ignition EI Probe Low Water Cutoff ...

Страница 34: ...34 Figure 37 Wiring Diagrams Steam Intermittent Ignition HSP Probe Low Water Cutoff ...

Страница 36: ...36 Figure 38 Wiring Diagrams Steam Continuous Ignition Standing Pilot Float Low Water Cutoff ...

Страница 38: ...38 Figure 39 Wiring Diagrams Steam Intermittent Ignition EI Float Low Water Cutoff ...

Страница 40: ...40 Figure 40 Wiring Diagrams Steam Intermittent Ignition HSP Float Low Water Cutoff ...

Страница 42: ...42 Figure 41 Wiring Diagrams Water Continuous Ignition Standing Pilot Intermittent Circulation ...

Страница 44: ...44 Figure 42 Wiring Diagrams Water Intermittent Ignition EI Intermittent Circulation ...

Страница 46: ...46 Figure 43 Wiring Diagrams Water Intermittent Ignition HSP Intermittent Circulation ...

Страница 48: ...48 Figure 44 Wiring Diagrams Water Continuous Ignition Standing Pilot Gravity Circulation ...

Страница 50: ...50 Figure 45 Wiring Diagrams Water Intermittent Ignition EI Gravity Circulation ...

Страница 52: ...52 Figure 46 Wiring Diagrams Water Intermittent Ignition HSP Gravity Circulation ...

Страница 54: ...54 Figure 47 Wiring Diagrams Water Continuous Ignition Standing Pilot Tankless Heater ...

Страница 56: ...56 Figure 48 Wiring Diagrams Water Intermittent Ignition EI Tankless Heater ...

Страница 58: ...58 Figure 49 Wiring Diagrams Water Intermittent Ignition HSP Tankless Heater ...

Страница 61: ...61 Figure 53 Lighting Instructions Continuous Ignition System VR8200 and VR8300 Gas Valves ...

Страница 62: ...62 Figure 54 Lighting Instructions Continuous Ignition System 7000 ERHC Gas Valve ...

Страница 64: ...64 Figure 56 Operating Instructions Intermittent Ignition System EI VR8304 IN12 only Gas Valves ...

Страница 65: ...65 Figure 57 Operating Instructions Intermittent Ignition System HSP SV9501 and SV9601 ...

Страница 76: ...76 ...

Страница 77: ...77 Honeywell Hot Surface to Pilot Trouble Shooting Guide ...

Страница 91: ...91 THIS PAGE LEFT BLANK INTENTIONALLY ...

Страница 92: ...92 ...

Страница 96: ...96 ...

Страница 99: ...99 THIS PAGE LEFT BLANK INTENTIONALLY ...

Страница 100: ...100 ...