5

Installation

Logano plus SB325 – 6 720 806 328 (2013/07)

25

5.11.1 Fitting the burner to the combustion chamber door

The burner connection dimensions of the combustion chamber door

comply with EN226:

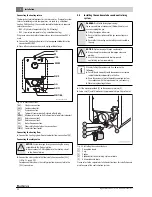

Fig. 28 Burner mounting dimensions in combustion chamber door

If the diameters of the blast tubes are larger than the holes provided,

please contact your supplier.

If the blast tube is not long enough to reach the inner edge of the thermal

insulation, a 45° chamfer can be applied to the thermal insulation.

The combustion chamber door must be opened to allow the burner to be

mounted.

▶ Open the combustion chamber door (

chapter 5.10.1, page 24).

▶ Push the gasket (included in the burner delivery) onto the blast tube.

▶ Fit the burner onto the combustion chamber door using the screws

supplied [2].

▶ Cut out insulating rings [4] to fit the diameter of blast tube [5].

▶ Fill the remaining gap on the inside of the combustion chamber door,

between combustion chamber door insulation [3] and blast tube [5],

with adapted insulating rings [4].

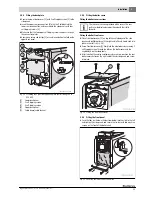

Fig. 29 Fitting the burner

[1]

Burner

[2]

Combustion chamber door

[3]

Thermal insulation for combustion chamber door

[4]

Insulating rings

[5]

Blast tube

▶ Close the combustion chamber door and tighten the hexagon bolts

(

chapter 5.10.1, page 24).

DANGER:

Injury/system damage through excess loads.

▶ Use suitable lifting gear for mounting the burner.

WARNING:

Damage to health, including skin and eye

irritation, as a result of inhaling or coming into contact

with fibre dust.

Fibre dust may be inhaled when working on the thermal

insulation and insulating rings.

▶ Wear a breathing mask and protective glasses with

side shields when working on the thermal insulation.

▶ Wear gloves and clothing that is loose-fitting around

the neck and wrists. Clean off dirty clothing before

removing or changing it (e.g. by vacuuming, although

never use compressed air).

NOTICE:

System damage through incorrect or missing

insulating rings.

▶ Only use the insulating rings supplied.

Refer to the installation instructions of the relevant

burner for its mounting and connection.

Boiler size SB325 [kW]

O

B

C

50-70

110

150

M8

90-115

130

170

M8

Tab. 13

45

°

C

A

B

6 720 804 354-19.1ITL

Installation of the insulating rings should be omitted if

this is specified in the installation information from the

burner manufacturer.

6 720 804 354-18.1ITL

4

1

2

3

5