2

About the appliance

Logano plus SB325 – 6 720 806 328 (2013/07)

5

2

About the appliance

2.1

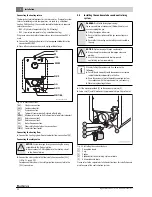

Type overview

2.2

Determined use

The Logano plus SB325 condensing boiler has been designed for hot

water heating systems in e.g. apartment buildings or industrial units.

The boiler is only approved for open flue operation.

Any pressure-jet gas burner type-tested to EN 676 can be used if its

operating range matches the boiler specifications.

Only burners that have been tested and approved for electromagnetic

compatibility (EMC) may be used.

2.3

Safety equipment

To ensure safe operation, the boilers must be equipped with the

following safety equipment:

• The level of safety equipment must comply with at least EN 12828.

• Also observe country-specific regulations if these specify further

requirements.

Equipment examples are included in chapter 11 , page 38. The

components comprising the safety equipment are available as

accessories.

2.4

EU Declaration of Conformity

The design and operation of this product conform to the applicable

European directives and supplementary national requirements.

Conformity has been demonstrated.

The Declaration of Conformity can be viewed at www.buderus.co.uk or

alternatively can be requested from your local Buderus sales office.

2.5

Scope of supply

▶ Upon receipt, check that all packaging is in perfect condition.

▶ Check the delivery is complete:

– 1 packed boiler supplied on a pallet.

– Technical documents, attached to boiler block.

– 1 boiler casing with thermal insulation and accessories, packed in a

carton.

– 1 siphon set supplied inside the combustion chamber.

– Insulating rings for blast tube supplied inside the combustion

chamber

It is possible that some of the standard accessories will not be necessary

for certain boiler types.

2.6

Required accessories

The following accessories are not part of the standard delivery but are

required to operate the boiler:

• Burner

• Boiler safety assembly

• Safety equipment

• Cleaning brushes

• Control unit.

2.7

Operating conditions

Type

Output

SB325

50 kW, 70 kW, 90 kW, 115 kW

Tab. 2 Type overview

Observe all standards and directives applicable to the

installation and operation of this heating system in your

country. Observe the information on the data plate.

These are definitive and must be observed.

Set the burner to the rated heat input QN specified on

the data plate as a maximum.

Conditions of use

Unit

Value

Maximum permissible temperature,

high-limit safety cut-out

°C

110

Maximum operating pressure

bar

4

Maximum number of burner starts

per annum

15 000

Tab. 3 Conditions of use

Operating conditions

Logano plus SB325

Logano plus SB325

Boiler water flow rate

None –

in conjunction with a

Logamatic control unit

for modulating

operation.

None –

in conjunction with a

Logamatic control unit

4212 for constant boiler

water temperatures or

when supplemented by a

third party control unit.

Min. boiler water

temperature

Operating Interruption

(complete boiler shut-

down)

Heating system control

with mixing valve

Minimum return

temperature

Miscellaneous

1)2)

1) Maximum 15,000 burner starts per year. In order not to exceed the number of

burner starts, observe the information on setting the control unit and burner in the

technical guide or installation instructions. If this value is exceeded, however,

please contact the manufacturer's service department.

2) The number of burner starts per year is affected by the boiler system's operating

settings (controller parameters in the boiler controller and combustion setting)

and sizing to correspond with the consumers' heat demand. To avoid exceeding

the number of annual burner starts as a result of operating settings which have not

been optimised, the manufacturer offers a complete commissioning and regular

document inspections for floor standing residential conventional boilers, burners

and boiler controller (Logamatic control units with function modules).

1)

Tab. 4 Operating conditions