5

Installation

Logano plus SB325 – 6 720 806 328 (2013/07)

21

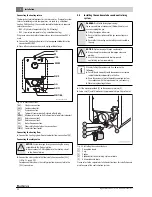

▶ Connect the drain hose [1] to the condensate drain with hose clips.

Fig. 17 Installing the neutralising system

[1]

Drain hose

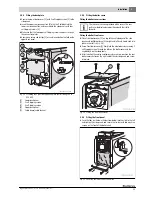

5.6

Installing the minimum pressure switch and minimum

pressure limiter (accessories)

▶ Connect the minimum pressure switch or minimum pressure limiter

(with R ½ to R¼ adaptor) to the MDW connection on the boiler.

Fig. 18 Boiler connections

5.7

Installing the low water level limiter (accessory)

▶ Install the low water level limiter on the low water level limiter

connection pipe (

Fig. 18, page 21).

▶ If the LWI connection is not being used for the installation of a low

water level limiter, remove the plastic plug and close off the LWI

connection with a blanking plug.

5.8

Filling the boiler and checking connections for leaks

Before commissioning, check the heating system for tightness to ensure

that no leaks will occur during operation.

▶ Fill the heating system with water (

chapter 6.1, page 28

and chapter 6.2, page 29).

▶ Check all connections for leaks.

▶ Pressure test the heating system.

▶ Check flange connection and boiler connections for leaks.

▶ Check the pipework for leaks.

▶ After the tightness test, reinstate all components that were taken out

of operation. Ensure that all pressure, control and safety equipment is

working correctly.

5.9

Fitting the casing

5.9.1

Fitting the connection plates

▶ Fit front tie bar (with trapezoid cut-out facing down) so that the

2 holes match up with the threaded pins at the top and fix with nuts.

▶ Fit rear tie bar (with trapezoid cut-out facing down) so that the 2 holes

match up with the threaded pins at the top and fix with nuts.

▶ Balance the front and rear connection plates with a spirit level.

Fig. 19 Locating and securing the front and rear tie-bars

You must ensure that the condensate generally runs via

the flue pipe into the boiler. If this is not possible, use

only stainless steel or plastic tees in the separate hose

line. With ceramic flue systems, fit a sludge separator

(sludge trap).

VK

M

VSL

MDW

AKO

RK2

RK1/EL

6 720 804 354-15.1ITL

AA

DANGER:

Risk of injury and/or system damage through

excess pressure when testing for leaks.

Pressure, control and safety equipment may be

damaged through excessive pressure.

▶ When carrying out the tightness test, ensure that no

pressure, control or safety equipment is fitted that

cannot be isolated from the boiler water chamber.

The test pressure level is subject to the system

components and to the heating system. Observe

country-specific regulations and standards.

The edge flanges on the cross-members must face

outwards and the front and rear cross members must be

horizontal and level with each other.

6 720 804 354-11.1ITL