10

Troubleshooting

Logano plus GB402 - Subject to technical modifications!

56

10.2

Operating and fault displays

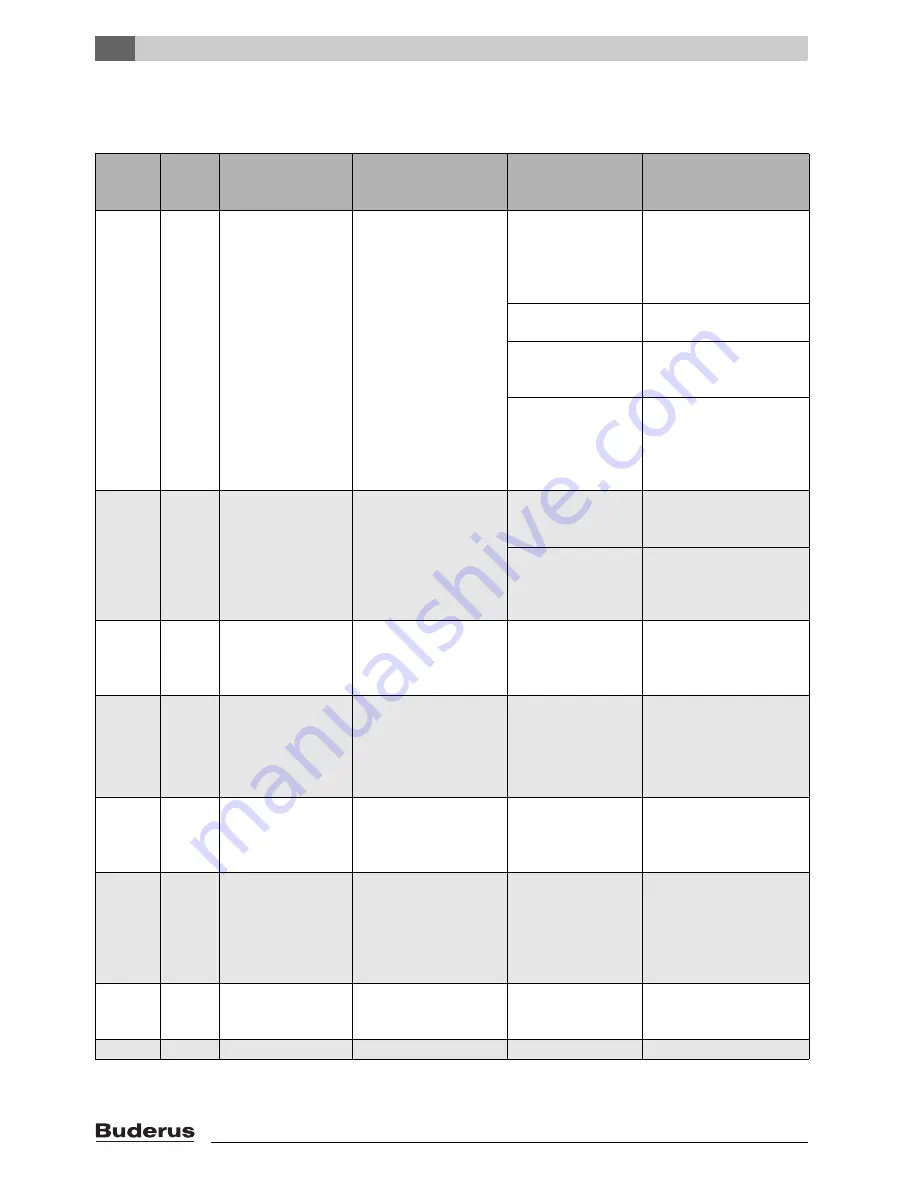

10.2.1 Operating messages

Display

code

Supple-

mentary

code

Cause

Description

Test procedure/

cause

Action

2P

564

Temperature rise at

the boiler sensor too

rapid ( > 70 K/min).

Heat exchanger

protection due to

excessively fast heat-up

speed.

No or insufficient

heat consumption

(e.g. thermostatic

valves or mixers

closed).

Ensure adequate heat

consumption.

Inadequate boiler

flow rate.

Install adequately sized

pumps.

Pump does not work. Check whether the pump

is being switched. Replace

the pump if required.

Deposits on the

water side of the

boiler (dirt from the

heating system,

scaling).

Flush/clean the boiler

block on the heating water

side with agents approved

for use with aluminium.

OA

-

Appliance in the

switching

optimisation routine.

A new burner demand

occurs within the set

switching optimisation

time. Appliance in cycle

block. The standard

switching optimisation

time is 10 min.

Check output setting

at the BC10 base

controller.

Match the boiler output to

the required heat demand

of the building.

Check the control

setting in the RC35

control unit.

Match the control setting

to the system conditions.

OH

-

The appliance is in

standby mode; there

is no heat demand.

The boiler is ready to

operate; there is no heat

demand from the heating

circuit.

-

-

OY

-

The current boiler

water temperature is

higher than the set

boiler water

temperature.

The current boiler water

temperature is higher

than the set boiler water

temperature.

The boiler shuts down.

-

-

OP

-

Waiting for the fan to

ramp up.

The ramp-up needs to be

detected for the

sequence to be able to

proceed.

-

-

OE

-

The appliance is in

standby mode, there

is an active heat

demand, but an

excess of energy is

being supplied.

The current system heat

demand is lower than

that which the minimum

modulation level of the

burner supplies.

-

-

OU

-

Start of the program

sequence to start the

burner.

-

-

-

OC

-

Burner start begins.

-

-

-

Tab. 20 Operating codes