577C--C, 577C--E, 577C--F: Installation Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

25

Normal Operation

An LED (light-emitting diode) indicator is provided on the integrated

gas unit controller (IGC) to monitor operation. The IGC is located by

removing the control access panel (see

). During normal

operation, the LED is continuously on (See

for error codes).

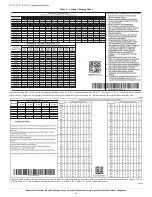

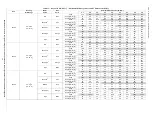

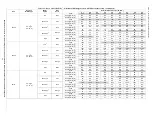

Airflow and Temperature Rise

The heating section for each size unit is designed and approved for

heating operation within the temperature-rise range stamped on the unit

rating plate.

,

and

show the approved temperature rise

range for each heating input, and the air delivery CFM at various

temperature rises for a given external static pressure. The heating

operation airflow must produce a temperature rise that falls within the

approved range. For single phase units only, “High” blower speed is for

high static cooling only and must not be used for gas heating speed.

Refer to Indoor Airflow and Airflow Adjustments section to adjust

heating airflow when required.

Heating Sequence of Operation (Single Phase

Models)

On a call for heating, terminal W of the thermostat is energized, starting

the induced-draft motor for a 5 second pre-purge. When the pressure

switch senses that the induced-draft motor is moving sufficient

combustion air, the burner sequence begins. This function is controlled

by the integrated gas unit controller (IGC). The indoor (evaporator) –fan

motor is energized 30 seconds after flame is established. When the

thermostat is satisfied and W is de-energized, the burners stop firing and

the indoor (evaporator) fan motor shuts off after a 90 second time-off

delay. Please note that the IGC has the capability to automatically reduce

the indoor fan motor on delay and increase the indoor fan motor off

delay in the event of high duct static and/or a partially-clogged filter.

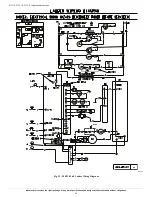

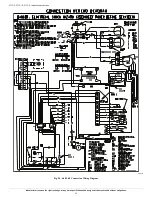

Heating Sequence of Operation (3 Phase Models)

, and

and unit wiring label.)

On a call for heating, terminal W of the thermostat is energized, starting

the induced-draft motor. When the pressure switch senses that the

induced-draft motor is moving sufficient combustion air, the burner

sequence begins. This function is performed by the integrated gas unit

controller (IGC). The indoor (evaporator)-fan motor is energized 45 sec

after flame is established. When the thermostat is satisfied and W is

de-energized, the burners stop firing and the indoor (evaporator) fan

motor shuts off after a 45-sec time-off delay. Please note that the IGC

has the capability to automatically reduce the indoor fan motor on delay

and increase the indoor fan motor off delay in the event of high duct

static and/or partially-clogged filter.

Limit Switches

Normally closed limit switch (LS) completes the control circuit. Should

the leaving-air temperature rise above the maximum allowable

temperature, the limit switch opens and the control circuit “breaks.” Any

interruption in the control circuit instantly closes the gas valve and stops

gas flow to the burners. The blower motor continues to run until LS

resets.

When the air temperature at the limit switch drops to the

low-temperature setting of the limit switch, the switch closes and

completes the control circuit. The direct-spark ignition system cycles

and the unit returns to normal heating operation.

Rollout Switch

The function of the rollout switch is to close the main gas valve in the

event of flame rollout. The switch is located above the main burners.

When the temperature at the rollout switch reaches the maximum

allowable temperature, the control circuit trips, closing the gas valve and

stopping gas flow to the burners. The indoor (evaporator) fan motor

(IFM) and induced draft motor continue to run until switch is reset. The

IGC LED will display FAULT CODE 7.

Step 3 – Start-up Cooling and Make Adjustments

Complete the required procedures given in the Pre-Start-Up section

before starting the unit. Do not jumper any safety devices when

operating the unit. Do not operate the compressor when the outdoor

temperature is below 40°F (4.4°C) (unless accessory low-ambient kit is

installed). Do not rapid-cycle the compressor. Allow 5 minutes between

on cycles to prevent compressor damage.

Checking Cooling Control Operation

Start and check the unit for proper cooling control operation as follows:

1. Place room thermostat SYSTEM switch in OFF position. Observe

that blower motor starts when FAN switch is placed in ON position

and shuts down when FAN switch is placed in AUTO position.

2. Place SYSTEM switch in COOL position and FAN switch in

AUTO position. Set cooling control below room temperature.

Observe that compressor, condenser fan, and evaporator blower

motors start. Observe that cooling cycle shuts down when control

setting is satisfied. The evaporator fan will continue to run for 90

sec.

3. When using an auto-changeover room thermostat, place both

SYSTEM and FAN switches in AUTO positions. Observe that unit

operates in Heating mode when temperature control is set to call for

heating (above room temperature) and operates in Cooling mode

when temperature control is set to call for cooling (below room

temperature).

IMPORTANT:

Three-phase, scroll compressors are direction oriented.

Unit must be checked to ensure proper compressor 3-phase power lead

orientation. If not corrected within 5 minutes, the internal protector will

shut off the compressor. The 3-phase power leads to the unit must be

reversed to correct rotation. When turning backwards, the difference

between compressor suction and discharge pressures will be minimal.

Table 7 – LED Indications

STATUS CODE

LED INDICATION

Normal Operation

*

*. LED indicates acceptable operation. Do not change ignition control board.

On

No Power or Hardware Failure

Off

Check fuse, low voltage circuit

1 Flash

Limit Switch Fault

2 Flashes

Flame Sense Fault

3 Flashes

Four Consecutive Limit Switch Faults

4 Flashes

Ignition Lockout Fault

5 Flashes

Pressure Switch Fault

6 Flashes

Rollout Switch Fault

7 Flashes

Internal Control Fault

8 Flashes

Temporary 1 hr auto reset

†

†. This code indicates an internal processor fault that will reset itself in one hr.

Fault can be caused by stray RF signals in the structure or nearby. This is a

UL requirement.

NOTES:

1. When W is energized the burners will remain on for a minimum of 60 sec.

2. If more than one error code exists they will be displayed on the LED in

sequence.

9 Flashes