577C--C, 577C--E, 577C--F: Installation Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

49

For models that have a scroll compressor, the compressor pumps

refrigerant throughout the system by the interaction of a stationary and

an orbiting scroll. The scroll compressor has no dynamic suction or

discharge valves, and it is more tolerant of stresses caused by debris,

liquid slugging, and flooded starts. The compressor is equipped with a

noise reducing shutdown device and an internal pressure relief port. The

pressure relief port is a safety device, designed to protect against

extreme high pressure. The relief port has an operating range between

550 (26.34 kPa) and 625 psig (29.93 kPa) differential pressure.

Refrigerant System

This information covers the refrigerant system including the compressor

oil needed, servicing systems on roofs containing synthetic materials, the

filter drier and refrigerant charging.

Compressor Oil

The Copeland scroll compressor uses 3MAF POE oil. If additional oil is

needed, use Uniqema RL32-3MAF. If this oil is not available, use

Copeland Ultra 32 CC or Mobil Arctic EAL22 CC. This oil is extremely

hygroscopic, meaning it absorbs water readily. POE oils can absorb 15

times as much water as other oils designed for HCFC and CFC

refrigerants. Take all necessary precautions to avoid exposure of the oil

to the atmosphere.

Rotary Compressor

The 24 and 30 size units use a single cylinder rotary compressor. This

compressor utilizes a rotor which is positioned eccentrically with respect

to the shell. Refrigerant gas is ported directly into the compression

chamber and discharged into the surrounding area. It is also known as a

“high-side” design since high pressure gas surrounds the motor and

compression chamber. The majority of the shell will be hot to the touch.

The rotary compressor also utilizes an external built-in accumulator to

reduce the likelihood of refrigerant liquid from entering the compressor.

Servicing Systems on Roofs with Synthetic

Materials

POE (polyolester) compressor lubricants are known to cause long term

damage to some synthetic roofing materials.

Exposure, even if immediately cleaned up, may cause embrittlement

(leading to cracking) to occur in one year or more. When performing any

service that may risk exposure of compressor oil to the roof, take

appropriate precautions to protect roofing. Procedures which risk oil

leakage include, but are not limited to, compressor replacement,

repairing refrigerant leaks, replacing refrigerant components such as

filter drier, pressure switch, metering device, coil, accumulator, or

reversing valve.

Synthetic Roof Precautionary Procedure

1. Cover extended roof working area with an impermeable

polyethylene (plastic) drip cloth or tarp. Cover an approximate 10

X 10 ft. (3.1 m X 3.1 m) area.

2. Cover area in front of the unit service panel with a terry cloth shop

towel to absorb lubricant spills and prevent run-offs, and protect

drop cloth from tears caused by tools or components.

3. Place terry cloth shop towel inside unit immediately under

component(s) to be serviced and prevent lubricant run-offs through

the louvered openings in the unit base.

4. Perform required service.

5. Remove and dispose of any oil contaminated material per local

codes.

Liquid Line Filter Drier

This filter drier is specifically designed to operate with Puron (R-410A).

Use only factory-authorized components. Filter drier must be replaced

whenever the refrigerant system is opened. When removing a filter drier,

use a tubing cutter to cut the drier from the system. Do not unsweat a

filter drier from the system. Heat from unsweating will release moisture

and contaminants from drier into system.

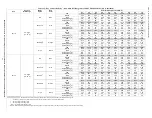

Puron (R-410A) Refrigerant Charging

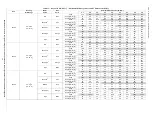

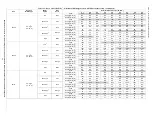

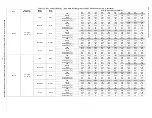

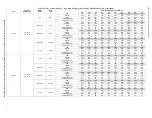

Refer to unit information plate and charging chart. Some R-410A

refrigerant cylinders contain a dip tube to allow liquid refrigerant to flow

from cylinder in upright position. For cylinders equipped with a dip tube,

charge Puron (R-410A) units with cylinder in upright position and a

commercial metering device in manifold hose. Charge refrigerant into

suction-line.

Troubleshooting

Use the Troubleshooting Guides (See

, and

if problems occur with these units.

Start-up Checklist

Use Start-Up checklist to ensure proper start-up procedures are followed.

My Learning Center is your central location for professional residential

HVAC training resources that help strenghten careers and businesses.

We believe in providing high quality learning experiences both online

and in the classroom.

Access My Learning Center with your HVACpartners credentials at

with questions.

WARNING

!

FIRE/EXPLOSION HAZARD

Failure to follow this warning could result in personal injury or death

and/or property damage.

Wear safety glasses and gloves when handling refrigerants. Keep

torches and other ignition sources away from refrigerants and oils.

WARNING

!

EXPLOSION, ENVIRONMENTAL SAFETY HAZARD

Failure to follow this warning could result in personal injury, death or

equipment damage.

This system uses Puron (R-410A) refrigerant which has higher

operating pressures than R-22 and other refrigerants. No other

refrigerant may be used in this system. Gauge set, hoses, and recovery

system must be designed to handle Puron (R-410A). If you are unsure,

consult the equipment manufacturer.