577C--C, 577C--E, 577C--F: Installation Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

53

Start-Up Checklist

(Remove and Store in Job Files)

I. PRELIMINARY INFORMATION

MODEL NO.: ____________________________________________

SERIAL NO.: ____________________________________________

DATE: __________________________________________________

TECHNICIAN:___________________________________________

II. PRESTART-UP (Insert check mark in box as each item is completed)

(¦ ) VERIFY THAT ALL PACKING MATERIALS HAVE BEEN REMOVED FROM UNIT

( ) REMOVE ALL SHIPPING HOLD DOWN BOLTS AND BRACKETS PER INSTALLATION INSTRUCTIONS

( ) CHECK ALL ELECTRICAL CONNECTIONS AND TERMINALS FOR TIGHTNESS

( ) CHECK GAS PIPING FOR LEAKS (WHERE APPLICABLE)

( ) CHECK THAT INDOOR (EVAPORATOR) AIR FILTER IS CLEAN AND IN PLACE

( ) VERIFY THAT UNIT INSTALLATION IS LEVEL

( ) CHECK FAN WHEEL, AND PROPELLER FOR LOCATION IN HOUSING/ORIFICE AND SETSCREW TIGHTNESS

III. START-UP

ELECTRICAL

SUPPLY VOLTAGE _______________________________________

COMPRESSOR AMPS ____________________________________

INDOOR (EVAPORATOR) FAN AMPS_______________________

TEMPERATURES

OUTDOOR (CONDENSER) AIR TEMPERATURE __________ DB

RETURN-AIR TEMPERATURE__________DB ___________ WB

COOLING SUPPLY AIR ________________ DB ___________ WB

GAS HEAT SUPPLY AIR __________________________________

PRESSURES

GAS INLET PRESSURE ___________________________ IN. W.C.

GAS MANIFOLD PRESSURE ______________________ IN. W.C.

REFRIGERANT SUCTION____________ PSIG,SUCTION LINE TEMP*___________________

REFRIGERANT DISCHARGE _________________PSIG, _______________LIQUID TEMP†

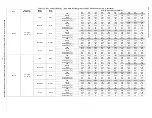

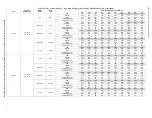

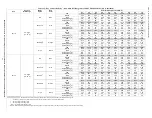

( ) VERIFY REFRIGERANT CHARGE USING CHARGING CHARTS

GAS HEAT TEMPERATURE RISE

TEMPERATURE RISE (See Literature) RANGE ________________

MEASURED TEMPERATURE RISE _________________________

* Measured at suction inlet to compressor

{

Measured at liquid line leaving condenser.