800SA/801SA: Installation, Start–Up, Operating and Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

30

7. Adjust blower off delay The blower off delay has 4 adjustable

settings from 90 sec to 180 sec. The blower off delay jumpers are

located on the furnace control board (see

).

To change the blower off delay setting, move the jumper from one

set of pins on the control to the pins used for the selected blower off

delay. Factory off delay setting is 120 sec.

8. Set airflow CFM for cooling

Select the desired blower motor speed lead for cooling airflow. See

-Air Delivery-CFM (With Filter) for lead color

identification.

Check Safety Controls

The flame sensor, gas valve, and pressure switch were all checked in the

Start-up procedure section as part of normal operation.

1. Check Main Limit Switch(es)

This control shuts off combustion control system and energizes

air-circulating blower motor, if furnace overheats. By using this

method to check limit control, it can be established that limit is

functioning properly and will operate if there is a restricted duct

system or motor failure. If limit control does not function during

this test, cause must be determined and corrected.

a. Run furnace for at least 5 minutes.

b. Gradually block off return air with a piece of cardboard or sheet

metal until the limit trips.

c. Unblock return air to permit normal circulation.

d. Burners will re-light when furnace cools down.

2. Check draft safeguard switch.

The purpose of this control is to cause the safe shutdown of the

furnace during certain blocked vent conditions.

a. Verify vent pipe is cool to the touch.

b. Disconnect power to furnace and remove vent connector from

furnace vent elbow.

c. Restore power to furnace and set room thermostat above room

temperature.

d. After normal start-up, allow furnace to operate for 2 minutes,

then block vent elbow in furnace 80 percent of vent area with a

piece of flat sheet metal.

e. Furnace should cycle off within 2 minutes. If gas does not shut

off within 2 minutes, determine reason draft safeguard switch did

not function properly and correct condition.

f. Remove blockage from furnace vent elbow.

g. Switch will auto-reset when it cools.

h. Re-install vent connector.

NOTE:

Should switch remain open longer than 3 minutes, furnace

control board will lockout the furnace for 3 hours. To reset furnace

control board, turn thermostat below room temperature or from HEAT to

OFF and turn 115v power OFF, then back ON.

3. Check Pressure Switch

This control proves operation of the draft inducer blower.

a. Turn off 115-v power to furnace.

b. Disconnect inducer motor lead wires from wire harness.

c. Turn on 115-v power to furnace.

d. Set thermostat to “call for heat” and wait 1 minute. When

pressure switch is functioning properly, hot surface igniter

should NOT glow and control diagnostic light flashes a status

code 31. If hot surface igniter glows when inducer motor is

disconnected, shut down furnace immediately.

e. Determine reason pressure switch did not function properly and

correct condition.

f. Turn off 115-v power to furnace.

g. Reconnect inducer motor wires, replace outer door, and turn on

115-v power.

h. Blower will run for 90 sec before beginning the call for heat

again.

i. Furnace should ignite normally.

Checklist

1. Put away tools and instruments. Clean up debris.

2. Verify that blower OFF-DELAY time is selected as desired.

3. Verify that blower and burner access doors are properly installed.

4. Cycle test furnace with room thermostat.

5. Check operation of accessories per manufacturer’s instructions.

6. Review User’s Guide with owner.

7. Attach literature packet to furnace.

SERVICE AND MAINTENANCE PROCEDURES

Untrained personnel can perform basic maintenance functions such as

cleaning and replacing air filters. All other operations must be performed

by trained service personnel. A qualified service person should inspect

the furnace once a year.

30

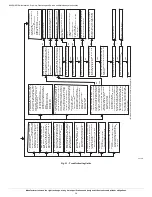

120 240 600

80

45

90

225

31

116 232 581

82

44

88

220

32

113 225 563

84

43

86

214

33

109 218 545

86

42

84

209

34

106 212 529

88

41

82

205

35

103 206 514

90

40

80

200

36

100 200 500

92

39

78

196

37

97 195 486

94

38

76

192

38

95 189 474

96

38

75

188

39

92 185 462

98

37

74

184

40

90 180 450

100

36

72

180

41

88 176 439

102

35

71

178

42

86 172 429

104

35

69

173

43

84 167 419

106

34

68

170

44

82 164 409

108

33

67

167

45

80 160 400

110

33

65

164

46

78 157 391

112

32

64

161

47

76 153 383

116

31

62

155

48

75 150 375

120

30

60

150

49

73 147 367

Table 13 – Gas Rate (Cu Ft./Hr.) (Continued)

SECONDS

FOR 1

REVOLUTION

SIZE OF TEST

DIAL

SECONDS

FOR 1

REVOLUTION

SIZE OF TEST

DIAL

1 Cu

Ft.

2 Cu

Ft.

5 Cu

Ft.

1 Cu

Ft.

2 Cu

Ft.

5 Cu

Ft.

WARNING

!

FIRE, INJURY, OR DEATH HAZARD

Failure to follow this warning could result in personal injury, death

and/or property damage.

The ability to properly perform maintenance on this equipment requires

certain knowledge, mechanical skills, tools, and equipment. If you do

not possess these, do not attempt to perform any maintenance on this

equipment other than those procedures recommended in the User’s

Manual.