800SA/801SA: Installation, Start–Up, Operating and Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

21

U.S.A.

— Refer to Sections 13.1.8 and 13.2.20 of the current edition of NFGC

NFPA54/ANSI Z223.1 or the authority having jurisdiction to determine whether

relining is required. If relining is required, use a properly sized listed metal liner,

Type-B vent, or a listed alternative venting design.

NOTE:

See the current edition of NFPA54/ANSI Z223.1, 13.1.8 and

13.2.20 regarding alternative venting design and the Exception, which

cover installations such as the Chimney Adapter Kits, which are listed

for use with these furnaces. See Product Data Sheet for accessory

listing.

The Chimney Adapter Kit is listed alternative venting system for these

furnaces. See the kit instructions for complete details.

This furnace is permitted to be vented into a clay tile-lined masonry

chimney that is exposed to the outdoors below the roof line, provided:

1. Vent connector is Type-B double-wall, and

2. This furnace is common vented with at least 1 draft hood equipped

appliance, and

3. The combined appliance input rating is less than the maximum

, and

4. The input rating of each space heating appliance is greater than the

minimum input rating given in

Design Temperature. Chimneys having internal areas greater than

38 square inches require furnace input ratings greater than the input

ratings of these furnaces. See footnote at bottom of

, and

5. The authority having jurisdiction approves.

If all of these conditions cannot be met, an alternative venting design

shall be used, such as the listed chimney adapter kit with these furnaces,

which are listed for use with the kit, a listed chimney-lining system, or a

Type-B common vent.

*The 99.6% heating db temperatures found in the 1997 or 2001 ASHRAE Fundamentals

Handbook, Climatic Design Information chapter, Table 1A (United States) or the 2005

ASHRAE Fundamentals handbook, Climatic Design Information chapter, and the CD-ROM

included with the 2005 ASHRAE Fundamentals Handbook.

WARNING

!

CARBON MONOXIDE POISONING HAZARD

Failure to follow the steps outlined below for each appliance connected

to the venting system being placed into operation could result in carbon

monoxide poisoning or death.

The following steps shall be followed for each appliance connected to

the venting system being placed into operation, while all other

appliances connected to the venting system are not in operation:

1.Seal any unused openings in venting system.

2.Inspect the venting system for proper size and horizontal pitch, as

required in the current edition of National Fuel Gas Code, ANSI

Z223.1/NFPA 54 and these instructions. Determine that there is no

blockage or restriction, leakage, corrosion and other deficiencies,

which could cause an unsafe condition.

3.As far as practical, close all building doors and windows and all doors

between the space in which the appliance(s) connected to the venting

system are located and other spaces of the building.

4.Close fireplace dampers.

5.Turn on clothes dryers and any appliance not connected to the venting

system. Turn on any exhaust fans, such as range hoods and bathroom

exhausts, so they are operating at maximum speed. Do not operate a

summer exhaust fan.

6.Follow the lighting instructions. Place the appliance being inspected

into operation. Adjust the thermostat so appliance is operating

continuously.

7.Test for spillage from draft hood equipped appliances at the draft

hood relief opening after 5 minutes of main burner operation. Use the

flame of a match or candle.

8.If improper venting is observed during any of the above tests, the

venting system must be corrected in accordance with the current edition

of National Fuel Gas Code, ANSI Z223.1/NFPA 54.

9.After it has been determined that each appliance connected to the

venting system properly vents when tested as outlined above, return

doors, windows, exhaust fans, fireplace dampers and any other

gas-fired burning appliance to their previous conditions of use.

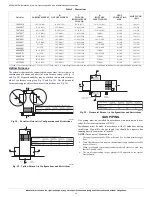

Table 8 – Combined Appliance Maximum Input Rating

in Thousands of Btuh per Hour

VENT HEIGHT

FT. (M)

INTERNAL AREA OF CHIMNEY

IN

2

(MM

2

)

12

(7741)

19

(12258)

28

(18064)

38

(24516)

6 (1.8)

74

119

178

257

8 (2.4)

80

130

193

279

10 (3.0)

84

138

207

299

15 (4.5)

NR

152

233

334

20 (6.0)

NR

NR

250

368

30 (9.1)

NR

NR

NR

404

Table 9 – Minimum Allowable Input Rating of Space-Heating

Appliance in Thousands of Btuh per Hour

VENT HEIGHT

FT (M)

INTERNAL AREA OF CHIMNEY

IN

2

. (MM

2

)

12

(7741)

19

(12258)

28

(18064)

38

(24516)

Local 99% Winter Design

Temperature: 17 to 26°F (-8 to -3°C)

6 (1.8)

0

55

99

141

8 (2.4)

52

74

111

154

10 (3.0)

NR

90

125

169

15 (4.6)

NR

NR

167

212

20 (6.1)

NR

NR

212

258

30 (9.1)

NR

NR

NR

362

Local 99% Winter Design

Temperature: 5 to 16°F* (-15 to -9°C)

6 (1.8)

NR

78

121

166

8 (2.4)

NR

94

135

182

10 (3.0)

NR

111

149

198

15 (4.6)

NR

NR

193

247

20 (6.1)

NR

NR

NR

293

30 (9.1)

NR

NR

NR

377

Local 99% Winter Design

Temperature: -10 to 4°F* (-23 to -16°C)

6 (1.8)

NR

NR

145

196

8 (2.4)

NR

NR

159

213

10 (3.0)

NR

NR

175

231

15 (4.6)

NR

NR

NR

283

20 (6.1)

NR

NR

NR

333

30 (9.1)

NR

NR

NR

NR

Local 99% Winter Design

Temperature: -11°F (-24°C) or lower

Not recommended for any vent configuration.