800SA/801SA: Installation, Start–Up, Operating and Service and Maintenance Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

10

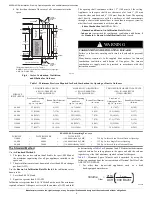

Leveling Legs (If Desired)

In upflow position with side return inlet(s), leveling legs may be used

(see

). Install field-supplied, 5/16 x 1-1/2 in. (8 x 38 mm) (max)

corrosion-resistant machine bolts, washers and nuts.

A89014

Fig. 12 – Leveling Legs

NOTE:

Bottom closure must be used when leveling legs are used. It

may be necessary to remove and reinstall bottom closure panel to install

leveling legs. To remove bottom closure panel, see Item 1. in Bottom

Return Air Inlet section.

To install leveling legs:

1. Position furnace on its back. Locate and drill a hole in each bottom

).

2. For each leg, install nut on bolt and then install bolt and nut in hole.

(Install flat washer if desired.)

3. Install another nut on other side of furnace base. (Install flat washer

if desired.)

4. Adjust outside nut to provide desired height, and tighten inside nut

to secure arrangement.

5. Reinstall bottom closure panel if removed.

LOCATION RELATIVE TO COOLING EQUIPMENT

The cooling coil must be installed parallel with, or on the downstream

side of the unit to avoid condensation in the heat exchangers. When

installed parallel with the furnace, dampers or other flow control must

prevent chilled air from entering the furnace. If the dampers are

manually operated, they must be equipped with means to prevent

operation of either unit unless the damper is in the full-heat or full-cool

position.

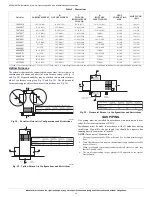

Suspended Furnace Support

The furnace may be supported under each end with threaded rod, angle

iron or metal plumber’s strap as shown (see

). Secure

angle iron to bottom of furnace as shown. Heavy-gauge sheet metal

straps (plumber’s straps) may be used to suspend the furnace from each

bottom corner. To prevent screws from pulling out, use 2 #8 x 3/4-in. (19

mm) screws into the side and 2 #8 x 3/4-in. (19 mm) screws in the

bottom of the furnace casing for each strap (see

). If

the screws are attached to ONLY the furnace sides and not the bottom,

the straps must be vertical against the furnace sides and not pull away

from the furnace sides, so that the strap attachment screws are not in

tension (are loaded in shear) for reliable support.

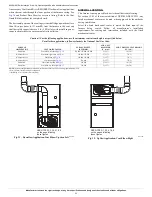

Platform Furnace Support

Construct working platform at location where all required furnace

clearances are met (see

and

). For furnaces with 1-in. (25

mm) clearance requirement on side, set furnace on noncombustible

blocks, bricks or angle iron. For crawl space installations, if the furnace

is not suspended from the floor joists, the ground underneath furnace

must be level and the furnace set on blocks or bricks.

A10164

Fig. 13 – Typical Attic Installation

A10130

Fig. 14 – Horizontal Unit Suspension

A10131

Fig. 15 – Horizontal Suspension with Straps

1

3

/

4

1

3

/

4

1

3/

4

1

3/

4

5/

16

5

/

16

5/

16

5/

16

(44mm)

(8mm)

(44mm)

(8mm)

(8mm)

(8mm)

(44mm)

(44mm)

30-IN. (762mm)

MIN WORK AREA

6

″

MIN

*

TYPE-B

VENT

17

3

/

4

″

22

″

SHEET

METAL

SEDIMENT

TRAP

EQUIPMENT MANUAL

SHUT-OFF GAS VALVE

LINE CONTACT ONLY PERMISSIBLE BETWEEN

LINES FORMED BY INTERSECTIONS OF

THE TOP AND TWO SIDES OF THE FURNACE

JACKET AND BUILDING JOISTS,

STUDS, OR FRAMING.

GAS

ENTRY

17

3

/

4

″

(451mm)OVERALL

4

3

/

4

″

(121mm) UNDER DOOR

1

″

(25mm) UNDER FURNACE

EXTEND OUT 12

″

(305mm)

FROM FACE OF DOOR

* WHEN USED WITH

SINGLE WALL VENT

CONNECTIONS

UNION

(152mm)

(451mm)

(559mm)

1

/

4

" (6mm) THREADED ROD

4 REQ.

SECURE ANGLE

IRON TO BOTTOM

OF FURNACE WITH

3 #8 x

3

/

4

" (19mm) SCREWS

TYPICAL FOR 2 SUPPORTS

1” (25mm) SQUARE, 1-1/4”x1-1/4”x1/8” (32x32x3mm)

ANGLE IRON OR UNI-STRUT MAY BE USED

(2) HEX NUTS, (2) WASHERS & (2) LOCK WASHERS

REQ. PER ROD

8" (203mm)

MIN

FOR DOOR REMOVAL

OUTER DOOR

ASSEMBLY

METHOD 2

USE (4) #8 x 3/4 (19 mm) SHEET

METAL SCREWS FOR EACH

STRAP. THE STRAPS

SHOULD BE VERTICAL

AGAINST THE FURNACE

SIDES AND NOT PULL AWAY

FROM THE FURNACE

SIDES.

METHOD 1

FOLD ALL STRAPS UNDER

FURNACE AND SECURE WTH

(4) #8 x 3/4 (19 mm) SHEET METAL SCREWS

(2 SCREWS IN SIDE AND 2 SCREWS

IN BOTTOM).