Bandit

22

Copyright 6/12

MODEL 200 UC

AUTOFEED TERMINOLOGY

AUTOFEED OPTIONS

PPR

Mag Pick-up

Dump Block

Reverse Valve

Dual Coil

Reverse Valve

Solenoid

High

Low

Back

Pulses per revolution. On magnetic pick‑up machines, this setting will be the number of

teeth on the gear or sprocket it is reading. On alternator pick‑up machines, the setting will

need to be obtained from your local dealer or Bandit Industries.

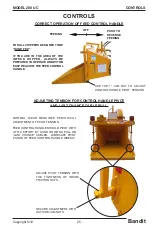

Magnetic pick‑up, also called pick‑up probe. This is normally located screwed into the

flywheel housing on the engine block. It can also be found on the clutch housing or chipper

shaft. See Figure 1.

This block is used in most cases. It is located near the fender on the frame of the chipper. An

easy way to find it is by following the hydraulic hose from the pump. The block will be the first

thing it is hooked into. This block also contains the main relief. When the solenoid is activated

(indicated by the light in the connector) the feedwheel(s) are stopped by the autofeed system.

See Figure 2.

Located on the infeed hopper of the chipper. It can be recognized by a valve with one solenoid

bolted on a square block. The solenoid is approximately 2‑1/2” (63.5mm) diameter x 2‑3/4”

(69.9mm) long. It will have two wires coming from it or on the newer machines it will have a

connector with a light screwed to it. When the solenoid is activated (indicated by the light in the

connector) the feedwheel(s) are reversed by the autofeed plus system. See Figure 3.

Normally seen on bigger machines such as 280, 1850, 1890, 1990, 2090, etc. and special

options. This will normally be located on the infeed hopper of the machine. It can recognized

by a valve with two solenoids bolted on a square block. The solenoid is approximately 2‑1/2”

(63.5mm) diameter x 2‑3/4” (69.9mm) long. It will have two wires coming from it or on the

newer machines it will have a connector with a light screwed to it. The feed coil must have

power (indicated by the light in the connector) for the feedwheels to feed and pull material

in. See Figure 4.

Electronically activated to produce a magnetic pull which shifts the spool inside the hydraulic

valve. Shifting of the spool changes oil flow direction from operating forward or dumping oil

to tank.

High or HI is the setting when the feedwheels will turn back on (feeding operation).

Low or LO is the setting when the autofeed will reverse (if equipped) the feedwheels and

then turn the feedwheels off.

Amount of time in seconds the feedwheels will back the wood away from the cutter disc/

drum. Normally this will be set at .3 seconds.

Figure 1

Figure 2

Figure 3

Connector

With Light

Autofeed Dump

Cartridge/Solenoid

Connector

With Light

Figure 4

Connector

With Light

Содержание 200 UC

Страница 17: ......

Страница 35: ...Bandit 19 Copyright 6 12 MODEL 200 UC DECALS ...

Страница 36: ...Bandit 20 Copyright 6 12 MODEL 200 UC DECALS ...

Страница 69: ...Bandit 53 Copyright 6 12 MODEL 200 UC HYDRAULIC SECTION HYDRAULIC SECTION ...

Страница 94: ...Bandit 78 Copyright 6 12 MODEL 200 UC INFEED HOPPER COMPONENTS Parts may not be exactly as shown NOTICE ...

Страница 96: ...Bandit 80 Copyright 6 12 MODEL 200 UC INFEED HOPPER COMPONENTS Parts may not be exactly as shown NOTICE ...

Страница 98: ...Bandit 82 Copyright 6 12 MODEL 200 UC CHIPPER COMPONENTS Parts may not be exactly as shown NOTICE ...

Страница 100: ...Bandit 84 Copyright 6 12 MODEL 200 UC CHIPPER COMPONENTS Parts may not be exactly as shown NOTICE ...

Страница 122: ...Bandit 106 Copyright 6 12 MODEL 200 UC Parts may not be exactly as shown NOTICE FUEL HYDRAULIC TANK COMPONENTS ...

Страница 126: ...Bandit 110 Copyright 6 12 MODEL 200 UC SERVICE RECORD SERVICE RECORD DATE DESCRIPTION AMOUNT ...