22

Ser

vi

ce

Proce

d

ure

II

:

Combust

i

on

System

T

est

i

ng

an

d

R

ep

l

acement

Ob

se

r

v

e

b

u

r

ne

r

ope

r

at

i

on

th

r

ou

gh

the

sight

g

l

ass

l

ocated

on

the

combustion

insert

mounting

f

l

ange

. N

orma

l

burner

operation

shou

l

d

ignite

smooth

l

y,

without

e

v

idence

of

coughing

or

huffing

upon

ignition

.

The

burner

f

l

ame

shou

l

d

be

a

b

l

ue

f

l

ame

near

the

burner

surface

in

a

uniform

f

l

ame

pattern

.

Occasiona

l

ye

ll

ow

or

white

streaks

are

norma

l.

N

ote:

On

th

i

s

h

i

gh

i

nput

mo

d

e

l

that

uses

meta

l

f

i

ber

mesh

burner

a

re

d

g

l

ow

from

the

burner

surface

i

s

norma

l.

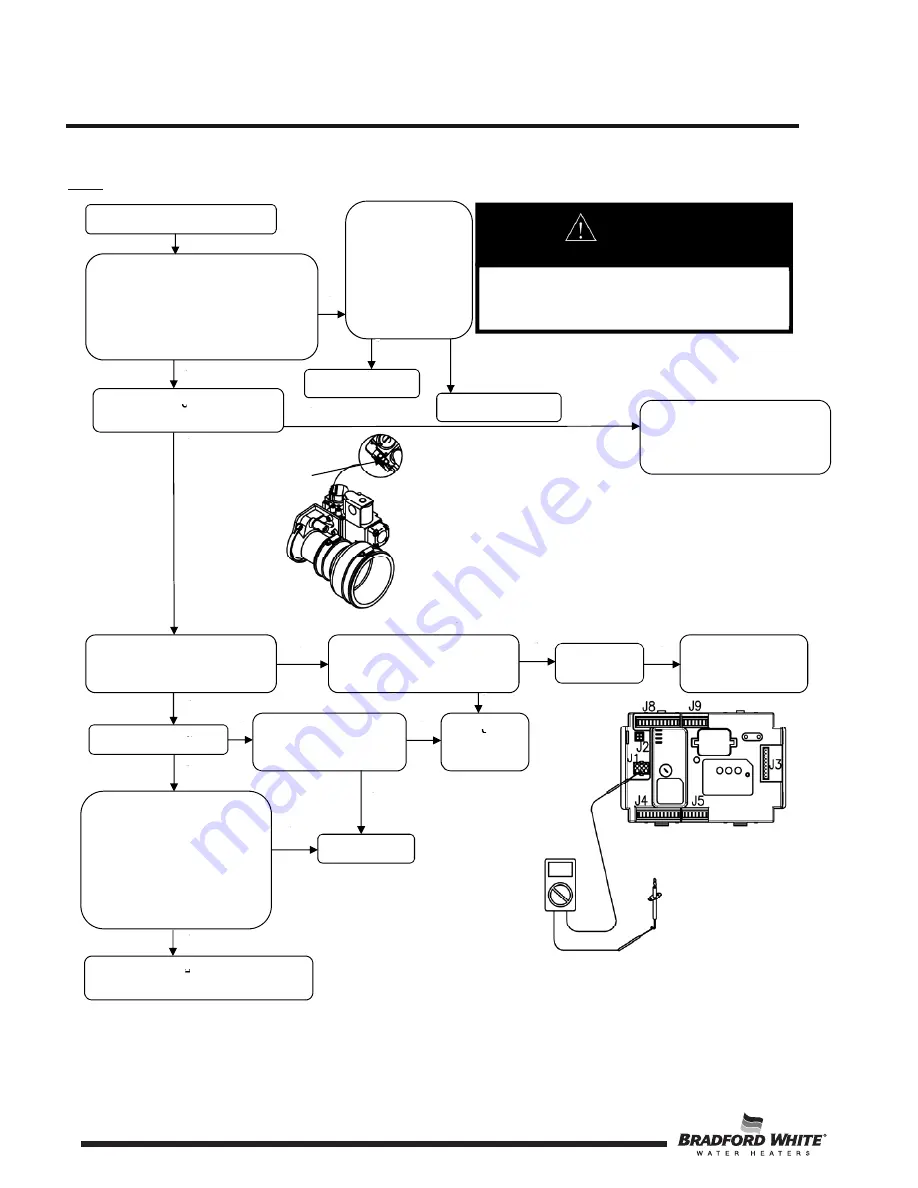

120

v

o

l

t

potentia

l

exposure

. I

so

l

ate

the

app

l

iance

and

reconfirm

power

is

disconnected

using

a

mu

l

ti

-

meter

.

WA

RN

I

N

G

Continued

from

pre

v

ious

page

N

Refer

to

contro

l

board

i

ll

ustration,

is

there

2

4

VAC

between

brown

and

b

l

ue

wires

coming

out

of

the

contro

l

harness

during

the

f

l

ame

estab

l

ishing

period

?

(

N

ote

:

Contro

l

disp

l

ay

must

show

“Heating”

for

operating

status)

.

Check

to

see

brown

and

b

l

ue

wires

are

proper

l

y

connected

to

mo

l

ex

connectors

on

contro

l

harness

.

Can

you

hear

or

fee

l

gas

v

a

lv

e

energize

?

Rep

l

ace

gas

v

a

lv

e

harness

and/or

gas

v

a

lv

e

.

(See

“Gas

Va

lv

e

Rep

l

acement

Procedure”

.

)

Does

burner

l

ight

smooth

l

y,

without

e

v

idence

of

coughing

or

huffing

?

Check

for

obstruction

at

in

l

et

of

gas

v

a

lv

e

. I

s

in

l

et

free

of

obstruction

?

C

l

ear

obstruction

I

nspect

burner

tube,

(see

“Burner

Tube

I

nspection”)

.

Does

burner

stay

l

it

?

Does

burner

operate

norma

ll

y

unti

l

thermostat

is

satisfied

?

Ca

ll

for

technica

l

support

Check

f

l

ame

sensor

.

Are

there

at

l

east

1

to

5

micro

amps

(min

.

)

during

1

.

5

second

f

l

ame

pro

v

ing

period

?

(Va

l

ue

may

be

disp

l

ayed

on

the

contro

l

disp

l

ay

by

accessing

“Ser

v

ice

Mode”

.

)

System

O

.

K

.

Rep

l

ace

f

l

ame

sensor

(see

“

Fl

ame

Sensor

Rep

l

acement

Procedure”)

.

gas

v

a

lv

e/

v

entur

i

Y

Y

N

Y

Y

Y

N

N

N

N

Y

Y

N

N

Rep

l

ace

contro

l

Make

connections

N

Y

I

n

l

et

Pressure

Tap

22