9000 Series Air Seeder

Service & Maintenance

10.10

10.1.3.3 Annually

1.

Tighten all fasteners to their specified torque.

2. Wash machine.

Note

Take care not to apply high pressure water

directly to any on-frame electrical switches or

boxes, scales, etc that are attached to the frame,

skirt or tanks of the unit.

3. Apply a coat of oil to all metering drive roller

chains and sprockets.

4. Brake Pads:

a. Check brake pads for wear on all four

calipers. If the thickness of the brake pad

is 1/8” or less it is recommended to change

the brake pad.

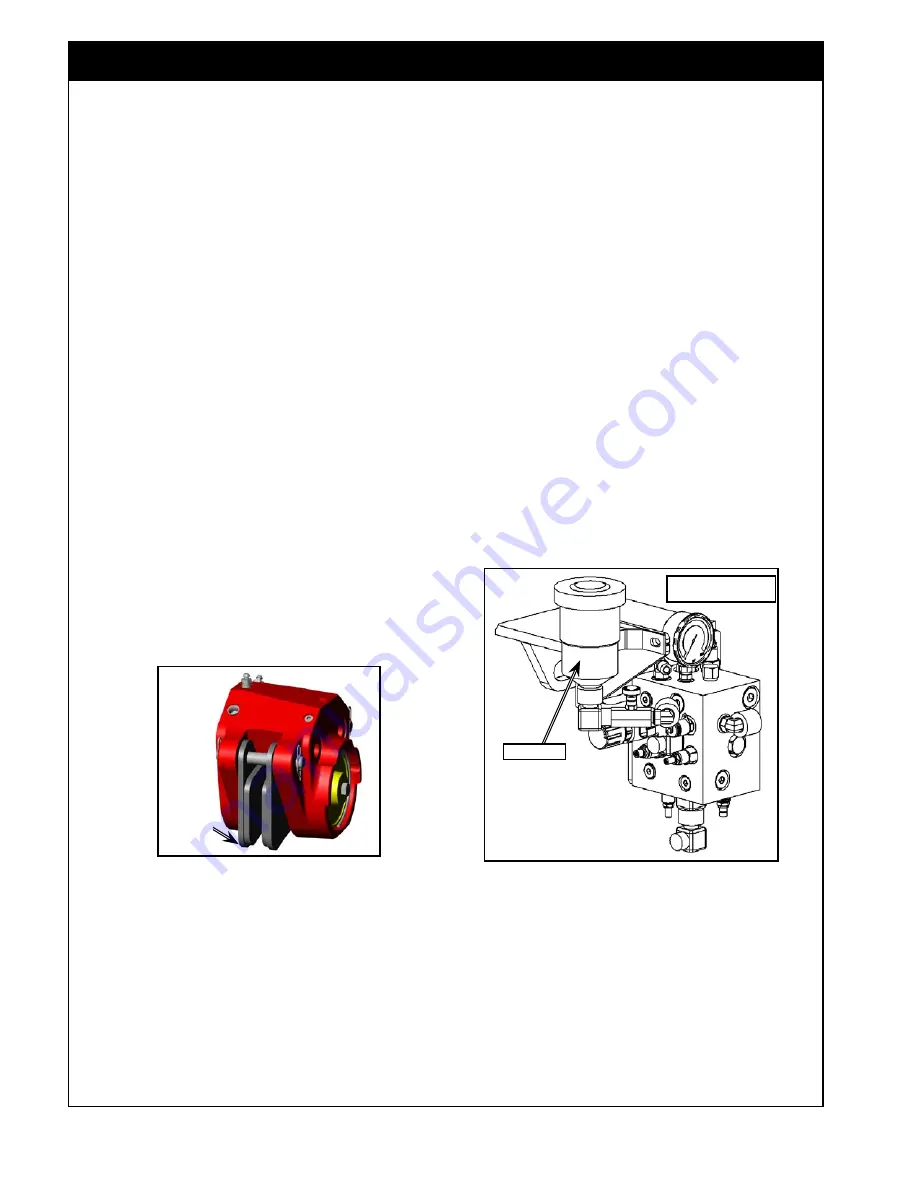

Figure 10.12 - Brake Reservoir

Figure 10.11 - Caliper - Brake Pads

Caliper_Pic1_22008670.jpg

Brake

Pads

5. Brake Reservoir:

a. Check level of ATF in the reservoir at the

beginning of each season.

b.

Ensure the fluid level never drops below

"Min." or is above "Max".

i.

Add Dexron ATF if necessary.

6. Surge Brakes:

a. Compress the hitch on the air seeder to

pressurize the brake system and slightly

open the needle valve, above the front axle

(on trailing) or at the front of the frame

truss (on leading), to release any air that

may have collected in the air trap.

Surge Brake System

Reservoir