Heat Recovery Package

|

41

SM Series Heat Pump

6 720 220 406 (2015/02)

Revised 02-15

Mode of operation Notes

1.

The Smart Start Assist has 2 indication LEDs on board.

The green LED indicates the status of the on-board power

supply while the red LED indicates an alarm condition or

the recovery time between starts.*

2. Once the main voltage is present, the green LED will be

fully ON. In case the main voltage is less than the stated

pickup voltage alarm value, the green LED will be flashing.

In case main voltage is higher than the stated pick-up

voltage and green LED is flashing, then this may indicate

that the on-board power supply is faulty. (Power Supply

Alarm)

3. Upon closing K1, the Smart Start Assist will start

ramping, duration of which is < 1 second, provided that the

minimum time from stop to start is respected. When

opening K1, the Smart Start Assist will stop without any

ramp down.

4. In the case of an under voltage, the Smart Start Assist

will shut down and the red LED flashes 2 times as long as

the under voltage is present. Once the main voltage is

restored the red LED will continue flashing for 5

minutes.Following these 5 minutes (6 minutes for HP

versions), the Smart Start Assist will start ramping function

in the case K1 is closed. The device can be reset at any

time by removing power on L1-N connection. When the

power is reapplied, the soft starter will star ramping up as

soon as K1 is closed, provided that the minimum time from

stop to start are respected.

5. If an over current (>80A for 1 sec.) is sensed, the Smart

start Assist will shut down and the red LED will flash 3

times indicating an over current situacion.This continues

for 5 minutes. In the case that the over current is still

present at the second attempt, user intervention is

required to reset the controller by cycling power for the

device to operate again as this implies that there are

problems in the system.

6. A detection circuitry provides protection in case of a

faulty starting capacitor EMR. In such situation, the red

LED will flash 4 times for 5 minutes. Smart Start Assist will

check the status of the starting capacitor EMR before

attempting a ramping function (in the case K1 is closed). If

at the second attempt, the starting capacitor EMR is found

to be faulty, user intervention is required to reset the

controller by cycling power for the device.

7. In the case of incomplete ramping of the Smart Start

Assist, the red LED will flash 5 times. The flashing will be

indicated by the red LED for 5 minutes. If after the second

attempt, there is another incomplete ramp alarm, user

intervention is required to reset the controller.

8. During the recovery from under-voltage, over-current

and incomplete ramp alarms, the red LED will flash twice

the normal flashing frequency using the same number of

flashes. The figure #108 shows the flashing in case of a

recovery from an under-voltage alarm.

9. During the recovery time between starts, the Smart Start

Assist will be continuously ON until the necessary recovery

time elapses.*

10. If Power supply on Smart Start Assist is removed

before the recovery period has elapsed, when supply is

restored, the delay will continue until the remaining

recovery time from the last start/stop (before supply

removal) is over. Following this, another start may be

attempted. If supply is removed during alarm recovery (red

LED flashing), when supply is restored, the alarm will be

reset and the Smart Start Assist will only wait for the

respective delays between starts and/or stop to start to

elapse before attempting another start (assuming K1 is

closed).

*Applicable to HP versions only

HEAT RECOVERY PACKAGE

Water Tank Preparation

1. Turn off electrical or fuel supply to the water

heater.

2. Attach garden hose to water tank drain

connection and run other end of hose out

doors or to an open drain.

3. Close cold water inlet valve to water heater

tank.

4. Drain tank by opening drain valve on the

bottom of the tank, then open pressure relief

valve or hot water faucet.

5. Once drained the tank should be flushed with

cold water until the water leaving the drain

hose is clear and free of sediment.

6. Close all valves and remove the drain hose.

7. Install HR water piping.

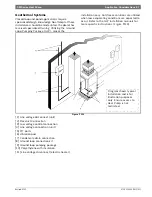

HR Water Piping

All hot water piping MUST be a minimum of 3/8”

O.D. copper tube to a maximum distance of 15

feet. For distances beyond fifteen feet but not

exceeding 60 feet use 1/2” copper tube.

Separately insulate all exposed surface of both

connecting water lines with 3/8” wall closed cell

insulation. Install isolation valves on supply and

return to the heat recovery. (Figure #109)

Concentric water fitting (p/n

8733907119

) is

recommended.