Maintenance and Repair

69/76

3 842 358 724/2013-04, MIT: BS 2/C-… + BS 2/R-…,

Bosch Rexroth AG

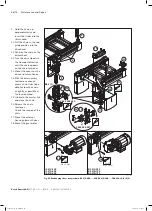

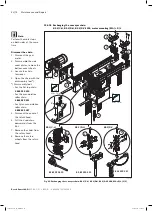

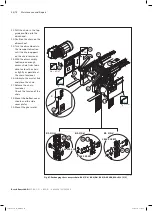

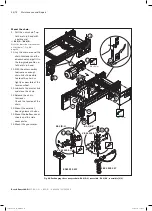

10.4.22 Exchanging the motor and/or gear:

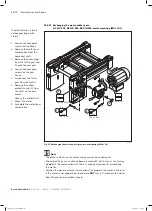

BS 2/C-100, BS 2/R-300, BS 4/R-300, motor mounting (MA) = M

Fig. 52:

547 601-64

3

SW8

M

D

= 5 Nm

(4x)

X

4

1

SW8

M

D

= 5 Nm

(2x)

gleitmo 585K

2

Antiseize

Exchanging the motor and/or gear, motor mounting (MA) = M

Note:

• The plane surfaces on the motor and gear must be undamaged.

• The hub of the gear has already been greased with ‘Anti-Seize’ at the factory.

• Do

not tilt the motor, make sure there is enough clearance for assembling

the motor.

• Position the motor correctly (terminal box!) and mount the motor in the gear.

If the motor is not properly positioned: do

NOT turn it. Disconnect the motor

from the gear and assemble it again.

For dismounting the drive

train see Exchanging the

conveyor chain, page 59,

step 1 to step 7.

The drive train does not

have to be dismounted

if only the motor has

to be replaced.

In that case begin with

step 4.

1.

Loosen the hexagonal

screws on the fl ange.

2.

Disconnect the motor/

gear combination from

the drive train.

3.

Loosen the hexagonal

screws on the gear

fl ange.

4.

Disconnect the faulty

gear from the motor.

5.

Remove the yellow

protective cap (X) from

the shaft on the new

motor.

Grease the motor shaft.

6.

Assemble the motor.

7.

Assemble the drive train.

For assembling the drive

train see Exchanging the

conveyor chain, page 61,

step 12 to step 21.

EN

GLISH

358724_2013_04_EN.indd 69

358724_2013_04_EN.indd 69

27.05.2013 13:08:18

27.05.2013 13:08:18