Form No. 1045-69 r5/21/14 © 2014 Bobrick Washroom Equipment, Inc. Printed in U.S.A.

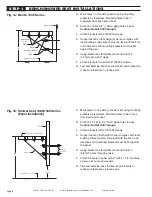

''D''

Finish Face of Floor

Sheet Metal

Screws

3/4''

19mm

Masonry Wall

Bracket

Sheet Metal Screws

2''

50mm

''D''

Finish Face of Floor

Panel

Bracket

Plain

Washers

Phenolic Shower Seat

12''

305mm

STEP 1

BENCH/SHOWER SEAT INSTALLATIONS

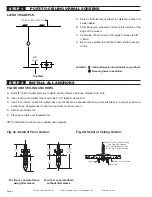

Fig. 1a: Bench 1040 Series

Fig. 1b: Shower Seat 1080/1180 Series

(Panel Installation)

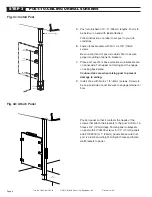

A. Mark holes on one side of shower seat using mounting

brackets as templates. Mounting holes to be 3" max.

from each end of seat.

B. Drill #19 x 7/16" (5.5 x 11mm) deep holes in seat.

Caution: Do Not Drill Through.

C. Attach brackets with #1002499 screws.

D. Support seat so that height of seat complies with local

building codes. Seat must be level with the floor in all

directions and mounting brackets must be flat against

the panel.

E. Using brackets as templates mark and drill #10

(4.8mm) holes through panels.

F. Attach brackets to panel with #10-32 x 1-1/4" machine

screws, hex nuts and washers.

G. Test and examine seat, fasteners and brackets to

make sure there are no loose parts.

A. Mark holes on one side of bench using mounting

brackets as templates. Mounting holes to be 3"

maximum from each end of seat.

B. Drill #19 (.166) x 3/4" (19mm) deep holes in seat.

Caution: Do Not Drill Through.

C. Attach brackets with #1002500 screws.

D. Support bench so that height of bench complies with

local building codes. Bench must be level with the floor

in all directions and mounting brackets must be flat

against the wall.

E. Using brackets as templates mark and drill #19

(4.2mm) into wall 2" deep.

F. Attach brackets to wall with #1002495 screws.

G. Test and examine bench and fasteners and brackets to

make sure there are no loose parts.

Page 8