Form No. 1045-69 r5/21/14 © 2014 Bobrick Washroom Equipment, Inc. Printed in U.S.A.

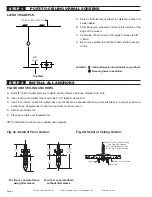

5/8"

16mm

Finish Face of Wall

2-1/2''

65mm

3-1/2''

90mm

2-1/2''

65mm

Cut to

4-3/4''

120mm

Overall

2''

50mm

Min.

Finish Face of Ceiling

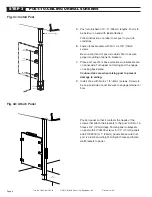

Drill 1/2'' (

12mm

) Hole in Ceiling.

Run Toggle Bolt through

Base Plate and Spacer, then

into Ceiling. Tighten securely.

Base Plate

Spacer

FLOOR AND CEILING ANCHORS.

A. Drill 3/8" (9.5mm) diameter hole to depth shown. Remove all loose material from hole.

B. Insert anchor into drilled hole. Stud to be 2-1/2" (65mm) above floor.

C. Use 9/16" (14mm) wrench to tighten hex nut until anchor is expanded. Make sure shoe retainer is in proper position to

accept shoe. Angled ends to face front and rear of urinal screen.

D. Install second hex nut.

E. Place base plate over threaded rod.

NOTE: Wood-floor anchors are available upon request.

Fig. 2a: Detail of Floor Anchor.

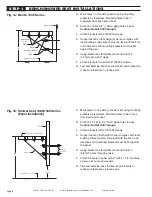

INSTALL ALL ANCHORS

STEP 2

For tile or concrete floors

using filler sleeve

For tile or concrete floors

without filler sleeve

A. Refer to Bobrick layout sheets for distance location on

screen depth.

B. From back wall, measure and mark the location of the

edge of the screen.

C. Centerline of floor anchor from edge of screen is 5/8"

(16mm).

D. Be sure, by plumb line, that floor and ceiling holes are

in line.

LAYOUT EXAMPLE.

POST-TO-CEILING URINAL SCREENS

STEP 1

LEGEND:

Obtain Dimension from Bobrick Layout Sheet.

Mounting holes to be drilled.

Fig. 2b: Detail of Ceiling Anchor.

Top View

Page 4