SECTION 10

ELECTRICAL COMPONENTS

10-1.ELECTRICAL CONTROL PANEL

10-1.1.Maintenance

NOTE:

Erratic operation of the truck may be caused

by defective controller components. Before

removing the electrical panel, perform trou-

bleshooting procedures per

, to

determine corrective action to be taken.

There are no user-serviceable parts inside the control-

ler. No attempt should be made to open the controller.

Opening the controller may damage it and will void the

warranty.

The controller is programmed at the factory specifi-

cally for the truck model on which it is equipped. It is

important to replace the controller with the correct pre-

programmed unit to assure proper performance set-

tings intended for that particular truck. See

for the preprogrammed controller number.

It is recommended that the controller exterior be

cleaned periodically, and if a Zapi Handset is avail-

able, this periodic cleaning provides a good opportu-

nity to check the controller’s diagnostic history file. It is

also recommended that the controller’s fault detection

circuitry be checked whenever the vehicle is serviced.

10-1.2.Cleaning

1.

Turn off the key switch (6,

) and dis-

connect the batteries.

2.

Remove the compartment covers as described in

paragraph

3.

Remove any dirt or corrosion from the bus bar

area. The controller should be wiped clean with a

moist rag. Allow it to dry before reconnecting the

battery.

4.

Make sure the connections to the buss bars are

tight. Use two well insulated wrenches for this

task in order to avoid steering the buss bars.

10-1.3.Panel

Removal.

1.

Turn off the key switch (6,

) and dis-

connect the batteries.

2.

Remove the compartment covers as described in

paragraph

3.

Tag and disconnect all electrical cables which

connect to the control panel (5,

4.

Remove two screws (1), two lock washers (2), two

flat washers (3), horn (4) and control panel (5).

10-1.4.Panel Disassembly.

Refer to

for location and identity of the

major replacement components mounted on the panel

and remove defective parts.

NOTE:

Contactor (10) is not repairable and must be

replaced if defective.

10-1.5.Panel Installation.

1.

Install the control panel (5,

) and horn

(4). Secure with two screws (1), two lock washers

(2) and two flat washers (3).

2.

Connect all electrical cables to the control panel

as noted during removal.

3.

Install the compartment covers as described in

paragraph

4.

Reconnect the batteries and turn on the keyswitch

(6,

10-2.HORN REPLACEMENT

1.

Turn off the key switch (6,

) and dis-

connect the batteries.

2.

Remove the compartment covers as described in

paragraph

3.

Tag and disconnect all electrical connections from

horn (4,

4.

Remove screws (1), lock washers (2), flat wash-

ers (3) and horn (4).

5.

Install horn and secure with screws (1), lock

washers (2), flat washers (3).

6.

Install the compartment covers as described in

paragraph

7.

Reconnect the batteries and turn on the keyswitch

(6,

69

Содержание BGL-22

Страница 12: ...NOTES 12...

Страница 18: ...NOTES 18...

Страница 34: ...NOTES 34...

Страница 39: ...Figure 5 4 Cap Assembly R6878 39...

Страница 42: ...Figure 6 1 Transmission Motor Brake Assembly R6879 42...

Страница 44: ...Figure 7 1 Transmission Motor Brake Assembly R6879 44...

Страница 45: ...Figure 7 2 Load Wheels R6882 45...

Страница 46: ...NOTES 46...

Страница 48: ...Figure 8 2 Elevation System Telescopic R6883 48...

Страница 50: ...Figure 8 3 Mast TRIMAST R6884 50...

Страница 52: ...NOTES 52...

Страница 54: ...Figure 9 1 Hydraulic System R6886 54...

Страница 56: ...Figure 9 3 Hydraulic System TRIMAST R6888 56...

Страница 58: ...Figure 9 4 Elevation System Telescopic R6883 58...

Страница 59: ...Figure 9 5 Lift Cylinder Telescopic R6889 59...

Страница 61: ...Figure 9 6 Elevation System TRIMAST R6884 61...

Страница 62: ...Figure 9 7 Free Lift Cylinder TRIMAST R6890 62...

Страница 64: ...Figure 9 8 Secondary Lift Cylinder TRIMAST R6891 64...

Страница 67: ...Figure 9 10 Tilt Cylinder R6893 67...

Страница 68: ...NOTES 68...

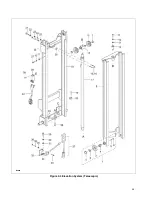

Страница 70: ...Figure 10 1 Electrical System R6478 R6894 70...

Страница 71: ...Figure 10 2 Electrical Panel R6478 R6895 71...

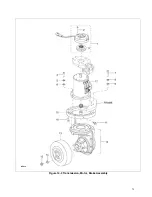

Страница 73: ...Figure 10 3 Transmission Motor Brake Assembly R6879 73...

Страница 74: ...NOTES 74...

Страница 75: ...SECTION 11 OPTIONAL EQUIPMENT 75...

Страница 76: ...NOTES 76...

Страница 78: ...Figure 12 1 Steering System R6876 78...

Страница 80: ...Figure 12 2 Control Head R6877 80...

Страница 82: ...Figure 12 3 Cap Assembly R6878 82...

Страница 85: ...NOTES 85...

Страница 86: ...Figure 12 5 Transmission Motor Brake Assembly R6879 86...

Страница 89: ...NOTES 89...

Страница 90: ...Figure 12 7 Frame R6881 90...

Страница 92: ...Figure 12 8 Load Wheels R6882 92...

Страница 94: ...Figure 12 9 Elevation System Telescopic R6883 94...

Страница 96: ...Figure 12 10 Elevation System TRIMAST R6884 96...

Страница 98: ...Figure 12 11 Lift Carriage R6815 98...

Страница 101: ...NOTES 101...

Страница 102: ...Figure 12 13 Hydraulic System R6665 102...

Страница 104: ...Figure 12 14 Pump Motor R6886 104...

Страница 107: ...NOTES 107...

Страница 108: ...Figure 12 16 Hydraulic System TRIMAST R6888 108...

Страница 110: ...Figure 12 17 Tilt Cylinder Mounting R6892 110...

Страница 112: ...Figure 12 18 Lift Cylinder Telescopic R6889 112...

Страница 114: ...Figure 12 19 Free Lift Cylinder TRIMAST R6890 114...

Страница 116: ...Figure 12 20 Secondary Lift Cylinder TRIMAST R6891 116...

Страница 118: ...Figure 12 21 Tilt Cylinder R6893 118...

Страница 120: ...Figure 12 22 Electrical System R6894 120...

Страница 123: ...NOTES 123...

Страница 124: ...Figure 12 24 Drive Motor R6630 124...

Страница 128: ...NOTES 128...

Страница 129: ...129...