11

4. FOR DORRIS MIXER TRANSMISSION

(OBSOLETE -N/A) BEFORE SERIAL NO. 55665

DORRIS MIXER TRANSMISSION: Oil in the mixer

transmission should be changed after the first four (4) weeks

of operation. This is to remove the “run in” oil and also any

small metal shavings that may have been generated during

the initial mating of the gears. After the first oil change,

subsequent changes should be performed every six (6)

months. After draining the oil, refill the unit to the “level”

plug (1 qt.) at the center of the transmission with a

petroleum based rust and oxidation (R&O) inhibited gear

oil. Viscosity Range for 15-75° F (-9 - 24° C) is

AGMA Lube No. 3 or ISO Grade 100.

TO CHANGE OIL:

a. Unplug mixer/grinder from power source and perform

lockout/tagout procedures.

b. Remove rear drive cover.

c. Remove breather plug from top of transmission and oil

level plug from side of transmission.

d. With a container in place to catch old oil, remove the

magnetic drain plug from the bottom of the transmission.

e. When all oil has drained, clean the drain plug and

replace into the transmission.

f. Refill transmission with approx. one (1) quart of the

recommended gear oils or equivalent. Or until oil

appears at bottom of oil level sight hole.

g. Replace breather and oil level plugs.

h. Carefully turn mixer transmission pulley by hand to

lubricate internal gears.

i. Reinstall rear drive cover.

D. MIXER DRIVE BELT TENSION

1. Unplug mixer/grinder from power source and perform lockout/tagout procedures.

2. Remove rear drive cover.

3. Loosen the four bolts holding the 1HP motor to its mounting plate.

4. Slide 1HP motor away from mixer transmission.

5. When approximately

½” total belt flex has been attained, re-tighten motor bolts.

6. Reinstall rear drive cover.

E. MAIN DRIVE CHAIN AND SPROCKET LUBRICATION:

The main drive chain has been pre-lubricated at the factory to protect it against dirt and moisture. Chain life

will vary appreciably depending upon its lubrication. The better the lubrication, the longer the chain life.

Lubrication effectiveness will vary with the amount of lubricant and frequency of application. Ideally, a lubricant

film should always be present between the working parts. Manually lubricate the chain as often

as is needed

(possibly once a week).

NEVER

exceed three months without lubricating.

Lubricating just outside of the chain does little good. Apply lubrication on the inside of the chain span so that

it will work through the moving parts and joints by centrifugal force as the chain rotates and reach the area

where one surface “scrubs” another.

SUGGESTED POPULAR NAME BRANDS:

R & O GEAR OILS

(RUST & OXIDATION INHIBITED)

COMPANY

ISO VISCOSITY GRADE

100 (AGMA3)

AMOCO

American Ind’l Oil 100

CHEVRON

Machine Oil R & O ISO 100

CITGO

Pacemaker Oil 100

CONOCO

Dectol R & O Oil 100

EXXON

Teresstic 100

MOBIL

DTE Heavy

PHILLIPS

Magnus Oil ISO VG 100

SHELL

Morlina Oil 100

SUN

Sunvis 9100

TEXACO

Regal Oil R & O 100

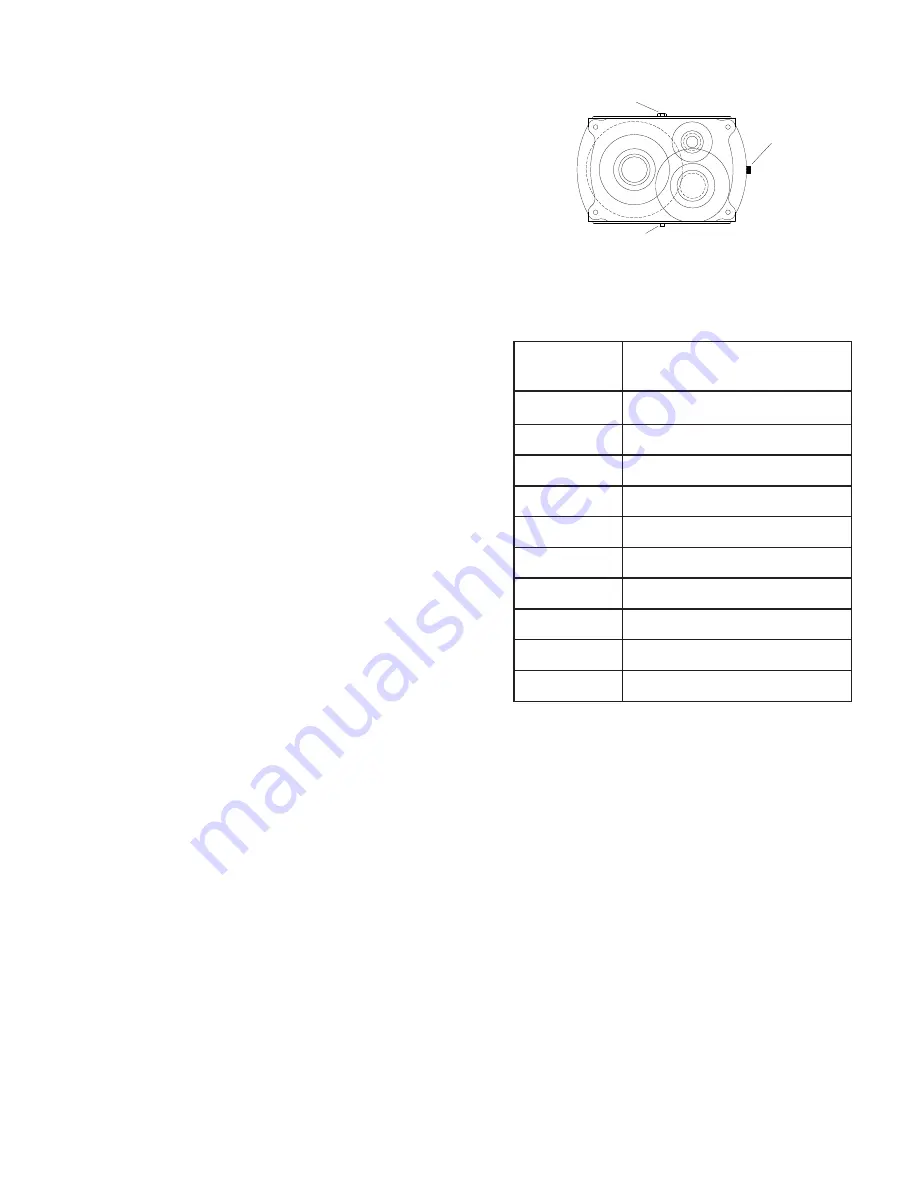

BREATHER PLUG

MAGENTIC DRAIN PLUG

OIL

LEVEL

PLUG

Содержание AFMG-52

Страница 16: ...14 OPTIONAL EAGLE BELT DRIVE SYSTEM ...

Страница 28: ...26 TANDEM OPERATION ILLUSTRATION FOR 35 INLET ...

Страница 29: ...27 WIRING DIAGRAM ...