3

51

M

O

TO

R C

H

EC

k

S AN

d

ASS

EM

B

LY

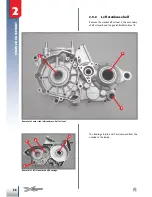

3.4 GEARBOx UNIT: CONTROLS

ANd REASSEMBLY

The gearbox unit is made up of the gearshift and

of the gearbox itself. The gearshift is then divided

into external and internal gearshift.

The following are the verifications and procedures

for checking and reassembling these units to the

engine.

3.4.1

Gearbox unit check

Use protective jaws to clamp the primary and

secondary shaft.

Use a thickness gauge to check the axial play

between the gearshift forks and the gearwheels.

The play detected must not exceed the service

limit indicated below:

service limit: 0,5mm

If the detected axial play is greater, before re-

placing either the gearwheels or the forks, check

their state of wear (par. 3.4.4).

Remove the various elements and check that:

• the support surfaces of the primary and sec-

ondary shafts are free of abnormal wear or

signs of seizure;

• the sides of the teeth are free from chipping or

abnormal wear;

• the sliding areas of the gearwheels are free

from abnormal wear or traces of seizure;

• the front claw clutches of the gearwheels are

not chipped or rounded;

• the roller bearings are intact and efficient;

• none of the thrust washers show traces of ab-

normal wear or meshing;

Should any of these defects present them-

selves, replace the concerned parts.

check of wear of forks and gearwheels.

Содержание X Trainer 300 2T 2015

Страница 1: ...CODE 036440030 000...

Страница 19: ...2 17 Engine disassembly Remove the four collar nuts 9 9 Extract the cylinder and base gaskets...

Страница 116: ...114 NOTES...

Страница 117: ......