QUADRA GREEN C.S.I.

12

table 1

MAXIMUM NUMBER OF

FAN ROTATIONS

METHANE

GAS (G20)

LIQUID GAS

(G31)

25 C.S.I.

heating - DHW

49 - 61

49 - 61

rpm

30 C.S.I.

heating - DHW

53 - 62

52 - 60

rpm

table 2

MINIMUM NUMBER OF

FAN ROTATIONS

METHANE

GAS (G20)

LIQUID GAS

(G31)

25 C.S.I.

14

14

rpm

30 C.S.I.

14

14

rpm

table 3

Max. CO

2

METHANE

GAS (G20)

LIQUID GAS

(G31)

25 C.S.I.

9,0

10,5

%

30 C.S.I.

9,0

10,5

%

table 4

Min. CO

2

METHANE

GAS (G20)

LIQUID GAS

(G31)

25 C.S.I.

9,5

10,5

%

30 C.S.I.

9,5

10,5

%

table 5

SLOW IGNITION

METHANE

GAS (G20)

LIQUID GAS

(G31)

25 C.S.I.

40

40

rpm

30 C.S.I.

40

40

rpm

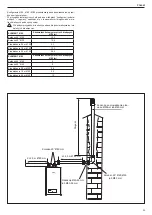

4.8 Gas conversion (fig. 42-43)

Gas conversion from one family of gases to another can also be easily

performed when the boiler is installed.

This operation must be carried out by professionally qualified personnel.

The boiler is designed to operate with methane gas (G20) according to the

product label.

It is possible to convert the boiler to propane gas, using the special kit.

For disassembly, refer to the instructions below:

- switch off the power supply to the boiler and close the gas tap

- remove in sequence: housing and air distribution box cover

- remove the fixing screw from the instrument panel

- unhook and turn the instrument panel forwards

- remove the gas valve (

A

)

- remove the nozzle (

B

) inside the gas valve and replace it with the nozzle

from the kit

- refit the gas valve

- remove the silencer from the mixer

- open the two half-shells by prising apart the corresponding hooks (

C

)

- replace the air diaphragm (

D

) in the silencer

- refit the air distribution box cover

- re-power the boiler and turn on the gas tap

Adjust the boiler as described in the chapter entitled “Adjustments” with

ref

erence to the information on LPG.

Conversion must be carried out by qualified personnel.

Once the conversion is co

mplete, affix the new identification

label supplied in the kit.

4.9 Checking the combustion parameters

To carry out the combustion analysis, proceed as follows:

- set the main switch of the installation to the “OFF” position

Method 1

- frontal procedure

- turn the selector to position

- chimney sweep function

Method 2

- board procedure

-

loosen the fixing screws (

D

) on the housing (fig. 13)

- move the base of the housing forwards and then upwards to unhook it

from the chassis

-

loosen the fixing screws (

E

) on the instrument panel (fig. 14)

- lift then turn the instrument panel towards you

-

loosen the fixing screws on the cover (

F

) to access the terminal board

(fig. 16)

-

using a small screwdriver included, press the CO button (fig. 26

)

Live electrical parts (230 V AC).

For both methods

-

Wait for burner ignition. The display shows “ACO”, the yellow LED flash

-

es and the boiler operates at maximum heat output.

-

Insert the analyser probe in the ports provided in the air distribution box,

after removing the screws from the cover (fig. 41).

- Check that the CO

2

values match those given in the table, if the value

shown is different, change it as indicated in the chapter entitled “Gas

valve calibration”.

-

Perform the combustion check.

Then:

- remove the analyser probe and close the sockets for combustion analy-

sis with the special screw

-

close the instrument panel and refit the housing.

The flue gas analysis probe must be fully inserted as far as pos

-

sible.

IMPORTANT

Even during the combustion analysis phase, the function that switches the

boiler off when the water temperature reaches the maximum limit (about

90°C) remains enabled.

5 MAINTENANCE

The appliance must be systematically controlled at regular intervals to

make sure it works correctly and efficiently and conforms to legislative pro

-

visions in force.

The frequency of controls depends on the conditions of installation and

usage, it being anyhow necessary to have a complete check carried out by

authorized personnel from the Servicing Centre every year.

- Check and compare the boiler’s performance with the relative specifica

-

tions. Any cause of visible deterioration must be immediately identified

and eliminated.

- Closely inspect the boiler for signs of damages or deterioration, particu-

larly with the drainage and aspiration system and electrical apparatus.

- Check and adjust – where necessary – all the burner’s parameters.

- Check and adjust – where necessary – the system’s pressure.

- Analyze combustion. Compare results with the product’s specification.

Any loss in performance must be identified and corrected by finding and

eliminating the cause.

- Make sure the main heat exchanger is clean and free of any residuals or

obstruction; if necessary clean it.

- Check and clean – where necessary – the condensation tray to make

sure it works properly.

After routine and extraordinary maintenance operations have

been carried out, fill the siphon, following the instructions in the

section “Switching on the appliance”.

IMPORTANT

: always switch off the power to the appliance and close the

gas by the gas cock on the boiler before carrying out any maintenance and

cleaning jobs on the boiler.

Do not clean the appliance or any latter part with flammable substances

(e.g. petrol, alcohol, etc.).

Do not clean panelling, enamelled and plastic parts with paint solvents.

Panels must be cleaned with ordinary soap and water only.

BURNER CLEANING

The

flame side of the burner is made with an innovative material of the

latest generation.

- Be especially careful during the dismantling, handling and installation of

the burner and the components next to it (e.g.. electrodes, insulation pa

-

nels, etc.)

- Avoid direct contact with any cleaning device (e.g. brushes, vacuum cle-

aners, blowers, etc.).

In general, the burner does not require maintenance, but particular cases

may occur where cleaning is necessary (e.g.. distribution network of gas

containing solid particles and in the absence of a filter on the line, suction

air containing excessively adhesive particulates, etc.).

For this reason, perform a visual control of the burner in order to ensure the

proper functioning of the product:

-

remove the front cover of the air box

- unscrew the fastening nut of the gas train to the valve, remove the gas

train spring clip to the mixer and turn the gas train outwards

-

remove the silencer from the mixer

- disconnect the connectors of the wiring from the fan and the connecting

cables of the electrodes

-

unscrew the fixing screws and remove the exchanger-fan cover assem

-

bly from its seat

-

unscrew the fixing screws and remove the burner from its seat checking

it condition.

If necessary, clean the burner with compressed air, blowing

from the metal side of the burner.

It is possible that with ageing, the fibres constituting the flame

side of the burner can tone the colour.

- Reassemble everything in reverse order

If necessary, proceed with the replacement of the sealing gas-

kets.

The manufacturer declines all responsibility for any damage caused from

the failure to observe that stated above.