19

EN

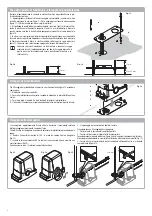

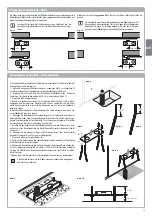

Fixing the end run brackets

Stopping the movement, in the opening phase and in the closing phase, takes place via

the end run brackets FRD.1, which, relevantly fixed onto the rack, make the end run

spring, present on the gear motor, intervene.

To position and fix the brackets FRD 1, proceed as follows:

1 -Take the leaf to the desired opening position. If a stop block is present on the ground,

the leaf must stop 2/3 cm before the block (Figure 20).

2 - Place the right bracket FRD.1 on the rack and make it slide until the end run spring,

bending, effects switch-over of the internal switch, which can be perceived with a

“click” (Figure 21).

3 - Fix the bracket temporarily via the two screws supplied (Figure 22).

4 - Take the leaf into the completely closed position and then open by about 2 cm

(Figure 23).

5 - Place the left bracket FRD.1 on the rack and make it slide until the end run spring,

bending, effects switch-over of the internal switch, which can be perceived with a

“click” (Figure 24).

6 - Fix the bracket as indicated in previous point 3.

7 - If necessary, use a hacksaw to shorten the end part of the last tract of the rack, so

that it does not project with respect to the plumb line of the leaf.

In the inspection phase, use several opening and closing manoeuvres to

ma

ma

ma

check whether the end run intervenes in the correct opening and closing

r the

ng

points, before the respective mechanical profiles.

the

If necessary, move the brackets FRD.1 to advance or delay the stop points

8 - When the best stop points have been established, remove the two screws, and use a

drill (45 mm point), to make the holes with depth of about 2 mm in correspondence with

the signs left by the screws and then fix bracket FRD.1 again (Figure 25).

A seat for the screws is created in this way, which guarantees the stability of the bracket

FRD.1 on the rack.

Fig. 20

2/3 cm

Fig. 22

Fig. 25

2/3 cm

CLICK!

CLICK!

Fig. 23

Fig. 24

Fig. 21

1 mm

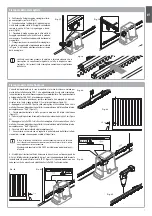

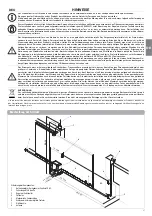

Fixing the rack

Fig. 18

Fig. 19

Fig. 17

4 - Checking that a space of about 1 mm remains

between the gear and rack (Fig.17).

5 - Make the leaf slide and take the driving gear near

to the second fixing fin, always checking the space of

1mm between gear and rack (Fig.18).

6 - Proceed in the same way for the other fins, moving

the leaf every time in a way always to have the correct

gear/rack coupling.

7 - Now continue with the remaining tracts of the

rack. Every tract must be attached to the previous one

as indicated in Figure 19, in a way to keep the rack

pitch constant.

Use several manual opening and closing manoeuvres to check that the

rack is correctly engaged, along its entire length. If necessary, the holes

present on the rack allow height adjustment.

Содержание 9592170

Страница 2: ......