Benezan Electronics

Hard- and software development

Triple Beast Installation Guide

Nicolas Benezan, Stauffenbergstr. 26, 72108 Rottenburg

Phone: +49 (0) 7457/946365 0 benezan-electronics.de

Page

TripleBeast-NET Installation.docx22.09.2020

Status LEDs

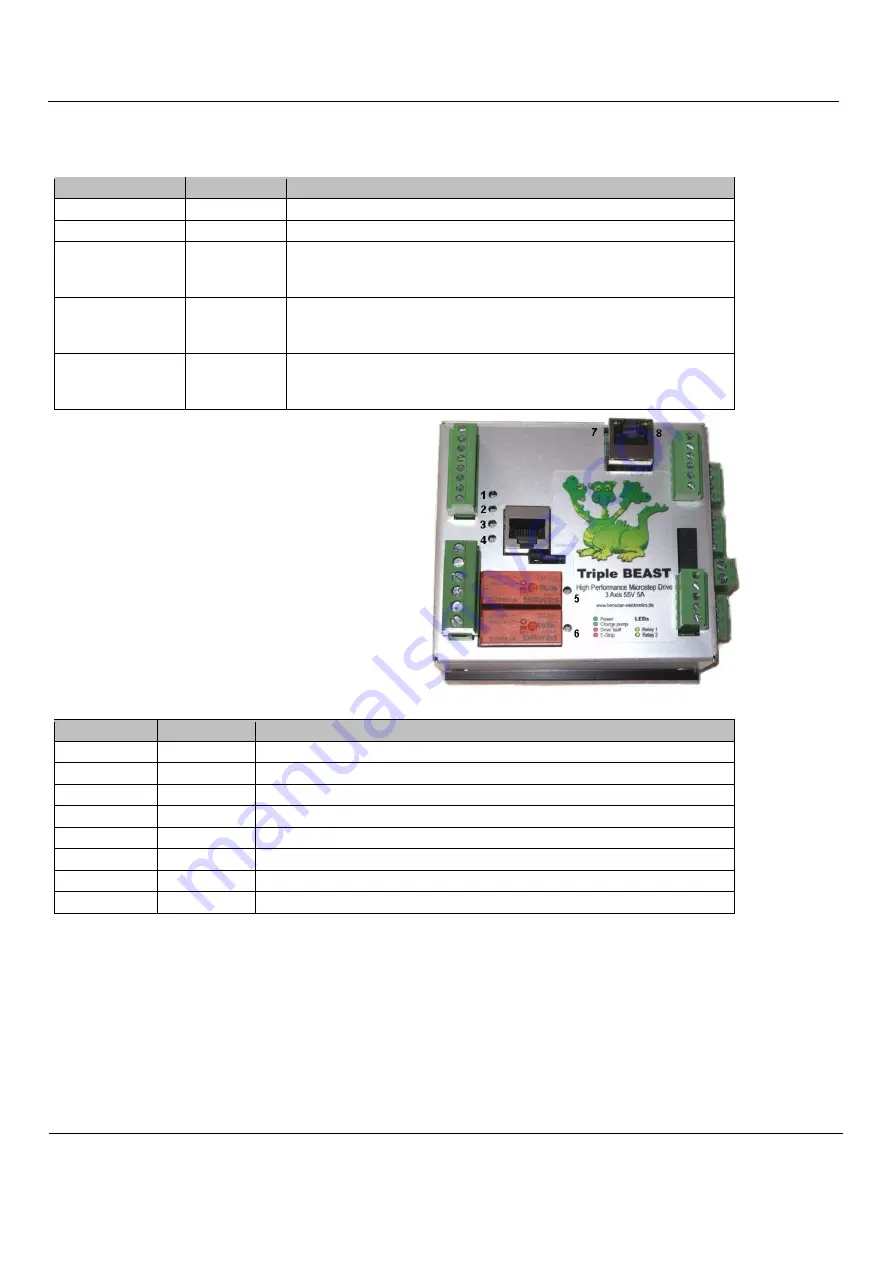

The status displays of the power amplifiers are located on the left side (see picture below). The different colours or combinations

thereof indicate the following operating states:

LEDs

Lettering

Description

(green)

Running

Motor(s) running, no current reduction

(yellow)

Standby

Motors stand still, current reduction

(red blinking)

Fault Axis... A single red flashing LED indicates a short circuit, overload or faulty

wiring on the corresponding motor. The other motors and the yellow or

green LED remain active.

(red blinking)

Fault Axis... If all red LEDs flash simultaneously when the green and yellow LEDs

are switched off, the output stage is overheated. All motors are switched

off.

(yellow/red

alternating)

Fault Axis... If the yellow and all red LEDs flash alternately, the power stage has been

deactivated due to overvoltage. The cause can be braking energy from the

motors or an incorrectly dimensioned power supply unit.

On the left below the middle of the housing, between

the RJ45 socket for the 4th axis and the relays, there is a

pin header with five contacts and two jumpers. These are

numbered from right to left with no. 12 to 16 and are

described further below.

The LEDs on the upper side indicate the status of the PC interface.

LEDs

Lettering

Description

1 (green)

Power

Power supply ok

2 (green)

Batch pump Watchdog (charge pump) active

3 (red)

Drive fault

One or more output stages report an error

4 (red)

E-Stop

Emergency stop switch activated or line interrupted

5 (yellow)

Relay 1

Relay 1 switched on (spindle motor)

6 (yellow)

Relay 2

Relay 2 switched on (coolant or suction)

7 (green)

-

Network connection established (Network carrier)

8 (yellow)

-

Network data transmission (network traffic)

PC / network connection

The data transfer from the PC software to the Triple BEAST takes place via an Ethernet network connection (IEEE802.3

10BASE-T). The connection can be made with standard patch cables at the RJ45 socket "N". Please note that the other RJ45

socket "A4" (without LEDs, see figure page 4) is not a network connection, but is intended for the step/direction signals of the

external 4th axis.

In contrast to similar products from competitors (e.g. Smoothstepper or Eding-CNC) no exclusive interface has to be reserved

on the PC, but the infrastructure of an existing network with switches can be used. There is also no need to change IP addresses or

otherwise interfere with the Windows Control Panel. The Beamicon2 software automatically recognizes the Triple BEAST, even

if it is connected "somewhere" in the network. To ensure reliable operation, however, the following rules must be observed: