Benezan Electronics

Hard- and software development

Triple Beast Installation Guide

Nicolas Benezan, Stauffenbergstr. 26, 72108 Rottenburg

Phone: +49 (0) 7457/946365 0 benezan-electronics.de

Page

TripleBeast-NET Installation.docx22.09.2020

The step and direction signals for a maximum of 4 axes are automatically assigned to the three motors and the RJ45 socket. No

settings need to be made for this. In particular, there is no need to set a pulse time, as the step signal always has a 50% duty cycle.

The direction of movement can be reversed in the machine parameters (Menu -> Configuration -> Machine) on the "Axis

Parameters" page with the "Inverted direction" button.

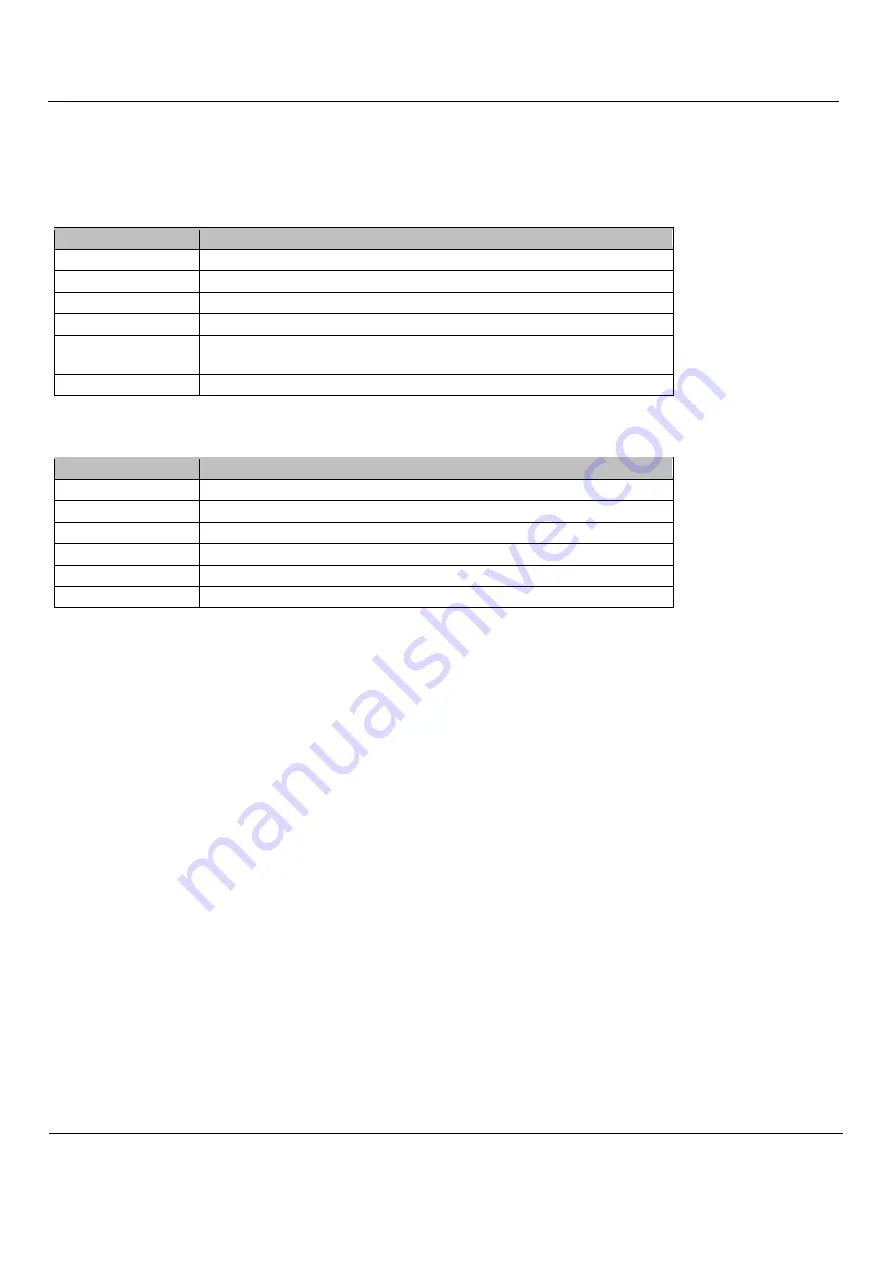

For the assignment of the signals switch to the page "Inputs/Outputs". The following input signals are available and can be

assigned to the logical signals (left table in the software):

Pin Name

Signal Description

Input 1

Switch input no. 1 (terminal X3.2)

Input 2

Switch input no. 2 (terminal X3.4)

Input 3

Switch input no. 3 (terminal X3.6)

Input 4

Switch input no. 4 (terminal X3.8)

Emergency stop

Emergency stop (triggered by mushroom button terminal X2.6, undervoltage

or connection error)

D error

Drive error, one of the stepper motor or servo output stages reports error

Input signals can be used multiple times if required. For example, the same switch input can be used simultaneously as a

reference and limit switch.

The following output signals are available and can be assigned to the logical signals (in the software right table):

Pin Name

Signal Description

Release

Current reduction signal or servo enable to the output stages

Relay 1

Relay no. 1, contacts X4.3 and X4.4

Relay 2

Relay no. 2, contacts X4.5 and X4.6

Brake

Relay for holding brake or frequency converter start, terminal X2.2

PWM

PWM signal for analog output, terminal X2.4

WDog

Watchdog/Charge-Pump-Signal, switches all outputs free

Unlike inputs, output signals cannot be inverted (active low/hi) because otherwise the safe off state would not be defined. For

the function of all other outputs the charge pump signal must be assigned to pin "WDog". Otherwise all outputs, including the step

signals, are disabled.

When using stepper motor output stages, the current reduction signal must be applied to the enable pin. This is always active

when all drives are stopped. When using servos, however, the servo enable signal must be assigned to the enable pin. This is

active when the drives are moving.

The relays can be assigned to any other output signals. Examples:

Standard assignment: Relay 1 = spindle forward, relay 2 = coolant, brake = holding brake

no brake, FU, add. spray cooling: relay1 = coolant, relay2 = spray cooling, brake = spindle forward

Spindle with right/left rotation: relay1 = spindle forward, relay2 = spindle reverse

If the number of available outputs or inputs is not sufficient for the application, they can be increased with an expansion

module.