8

2.7

WIRING

2.7.1

POWER WIRING

The 70E/70M Pump Control Panel can be set up to

operate across a broad range of voltages. It was fac-

tory set to operate on the voltage shown on the

nameplate. Verify proper transformer primary wiring

per the job-specific wiring diagram. Check power

leads in accordance with wiring diagram enclosed in

control cabinet. The voltage tolerance is +10%/-10%.

2.7.2

ANALOG SIGNAL WIRING

If installing the panel on an existing system, shielded

cable (#22 AWG, Belden type 8762, Alpha #2411 or

equal) should be installed for the DC control wiring.

The shield must be terminated in the 70E/70M con-

trol panel. Do not connect the shield at the other end

of the cable! Insulate the shield so that no electrical

connection is made at the other end of the cable. A

twisted pair of #22 AWG conductors (Belden 8442 or

equal) can be used in place of shielded cable. The

cable length must be limited to 3000 feet for #22

AWG wire.

2.7.2.1

PRESSURE TRANSMITTER WIRING

(4-20 mA Analog Signals)

2.7.2.2

TEMPERATURE SENSOR WIRING

(Analog Resistance Input)

The 70E/70M uses resistance temperature detectors

(RTDs) to sense the suction and discharge water

temperatures. These devices change their resistance

as the water temperature changes.

2.7.2.3

FLOW SENSOR/TRANSMITTER WIRING AND

INSTALLATION (4-20 mA Analog Signal) (Optional)

The flow sensor should be installed at an angle no

greater than 45 degrees from top dead center in a

horizontal installation (see manufacturer’s IOM). See

the Bell & Gossett drawing for installation instruc-

tions. The signal wiring should be terminated in the

70E/70M panel at the terminals below.

2.7.3

DIGITAL SIGNAL WIRING

2.7.3.1

DIFFERENTIAL PRESSURE SWITCH PIPING

AND WIRING (Digital Signal) (Optional)

Differential pressure switches installed to sense the

increase in pressure between the pump suction and

discharge gauge taps are used to determine whether

a pump is running. Each switch should be wired from

the normally closed contact to the terminals below.

2.7.3.2

LOW LEVEL CONTROL WIRING

(Digital Signal) (Optional)

The low water level control option is utilized when

drawing water from a tank. In this control circuit, two

electrodes sense the water level inside of a water

tank. When the water level drops below its minimum

level, the pressure booster will shut down.

2.7.3.3

REMOTE START-STOP (Digital)

Install a non-powered dry contact digital input to ter-

minals J4-1 and J4-2. With the LOCAL-REMOTE-

OFF switch in the REMOTE position this contact

closure will provide the start signal.

2.7.3.4

REMOTE ALARM INDICATION (Digital Signal)

A digital output dry contact rated 2 Amps at 115V is

supplied on terminals J5-7 and J5-8. This output

closes to indicate that an alarm condition exists.

2.7.3.5

PUMP ON/OFF REMOTE SIGNAL (Digital Signal)

A digital output dry contact (one per pump) rated 2

Amps at 115V is provided for remote monitoring of

pump On/Off status. This contact closes when a

pump is running.

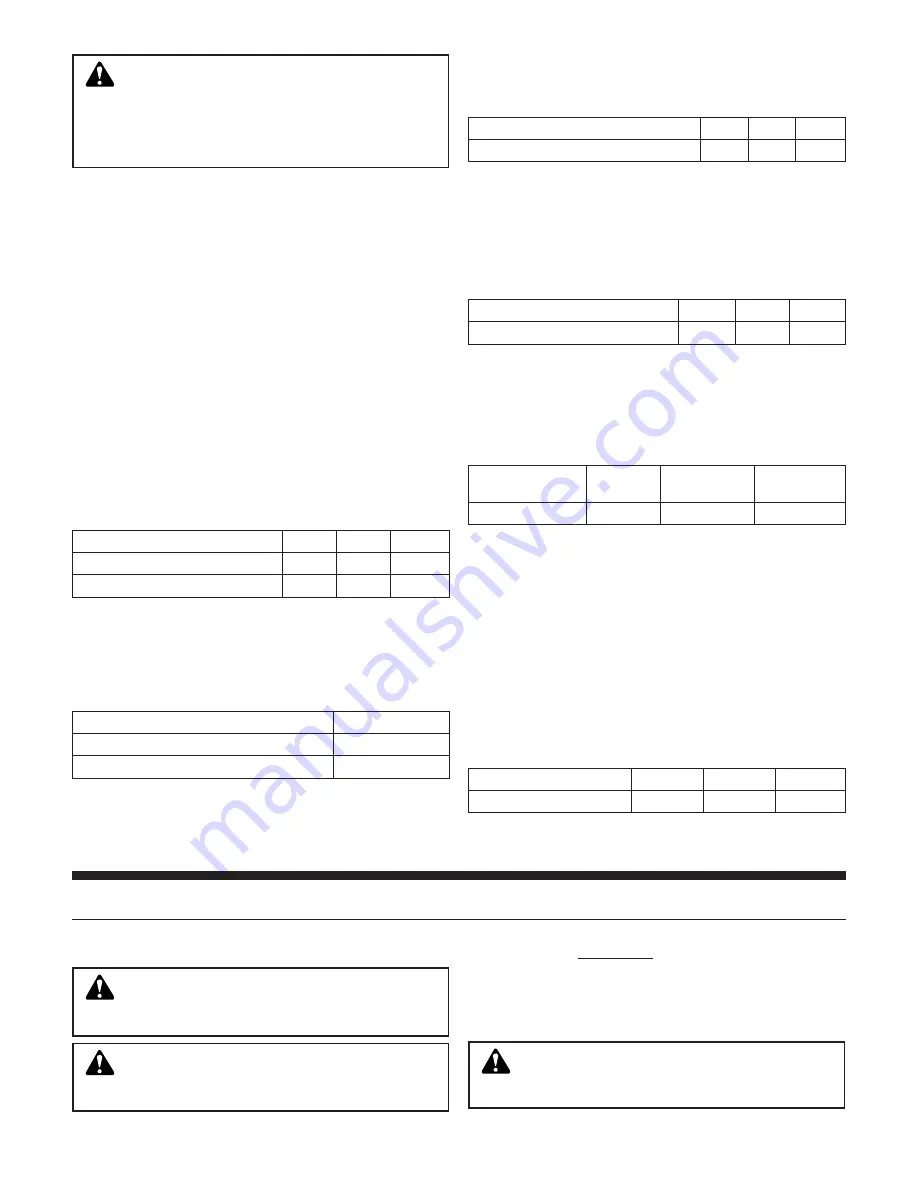

Terminals (J3)

+

-

Shield

Suction Pressure

3

2

4

System (discharge) Pressure

3

6

4

Temperature Sensor (RTD) Wiring

Terminals (J3)

Low Temperature Sensor (suction)

13, 14

High Temperature Sensor (discharge)

16, 17

Optional Flow Sensor/Transmitter

+

-

Shield

Terminals (J3)

9

8

10

Pump #

1

2

3

Terminals (J4)

9, 8

10, 11

11, 12

Pump On

Pump Off

Ground

Electrode

Electrode

Terminals (J4)

66

67

68

Pump On/Off Signal

Pump #1

Pump #2

Pump #3

Terminals (J5)

9, 10

11, 12

13, 14

3.0

PUTTING THE UNIT INTO SERVICE

3.1

PUMP ROTATION, 3 PHASE MOTORS ONLY

With the disconnect switch engaged to the “ON”

position, momentarily start and stop each motor with

the pump motor key on the key pad. See Paragraph

5.3 on page 16. Observe the pump shaft rotation.

3.2

If incorrect, turn the main disconnect off and inter-

change any two wire leads leaving the starter over-

load block and going to the motor.

3.3

Unit is now ready for operation (factory assembled

tested units only).

SECTION 3 – START UP

WARNING: Rotating shafts can catch loose cloth-

ing. Do not operate the pump without all guards in

place. Failure to follow these instructions could result in

serious personal injury, death, and/or property damage.

CAUTION: Seal Damage may occur. Do not run

pumps dry. Fill and vent the pump volute prior to

operation. Failure to follow these instructions could re-

sult in property damage and/or moderate personal injury.

DANGER: High Voltage 3 phase power can kill.

Disconnect and lockout power prior to servicing

unit. Failure to follow these instructions could result in

serious personal injury, death, and/or property damage.

DANGER: Electrical shock hazard. Inspect all elec-

trical connections prior to powering the unit. Wiring

connections must be made by a qualified electrician in

accordance with all applicable codes, ordinances, and

good practices. Failure to follow these instructions

could result in serious personal injury, death, and/or

property damage.