Technical description

20

DRYPOINT RA 200 – 2500 NA

5.9.

Filter Drier

Traces of humidity and slag can accumulate inside the refrigerating circuit. Long periods of use can also produce

sludge. This can limit the lubrication efficiency of the compressor and clog the expansion valve or capillary tube. The

function of the Filter Drier, located before the capillary tubing, is to eliminate any impurities from circulating through the

system.

5.10. Capillary Tube

It consists of a piece of reduced cross section copper tubing located between the condenser and the evaporator, acting

as a metering device to reduce the pressure of the refrigerant. Reduction of pressure is a design function to achieve

optimum temperature reached within the evaporator: the smaller the capillary tube outlet pressure, the lower the

evaporation temperature.

The length and interior diameter of the capillary tubing is accurately sized to establish the performance of the dryer; no

maintenance or adjustment is necessary.

5.11. Alu-Dry Module

The heat exchanger module houses the air-to-air, the air-to-refrigerant heat exchangers and the demister type

condensate separator. The counter flow of compressed air in the air-to-air heat exchanger ensures maximum heat

transfer. The generous cross section of flow channel within the heat exchanger module leads to low velocities and

reduced power requirements. The generous dimensions of the air-to-refrigerant heat exchanger plus the counter flow

gas flow allows full and complete evaporation of the refrigerant (preventing liquid return to the compressor). The high

efficiency condensate separator is located within the heat exchanger module. No maintenance is required and the

coalescing effect results in a high degree of moisture separation.

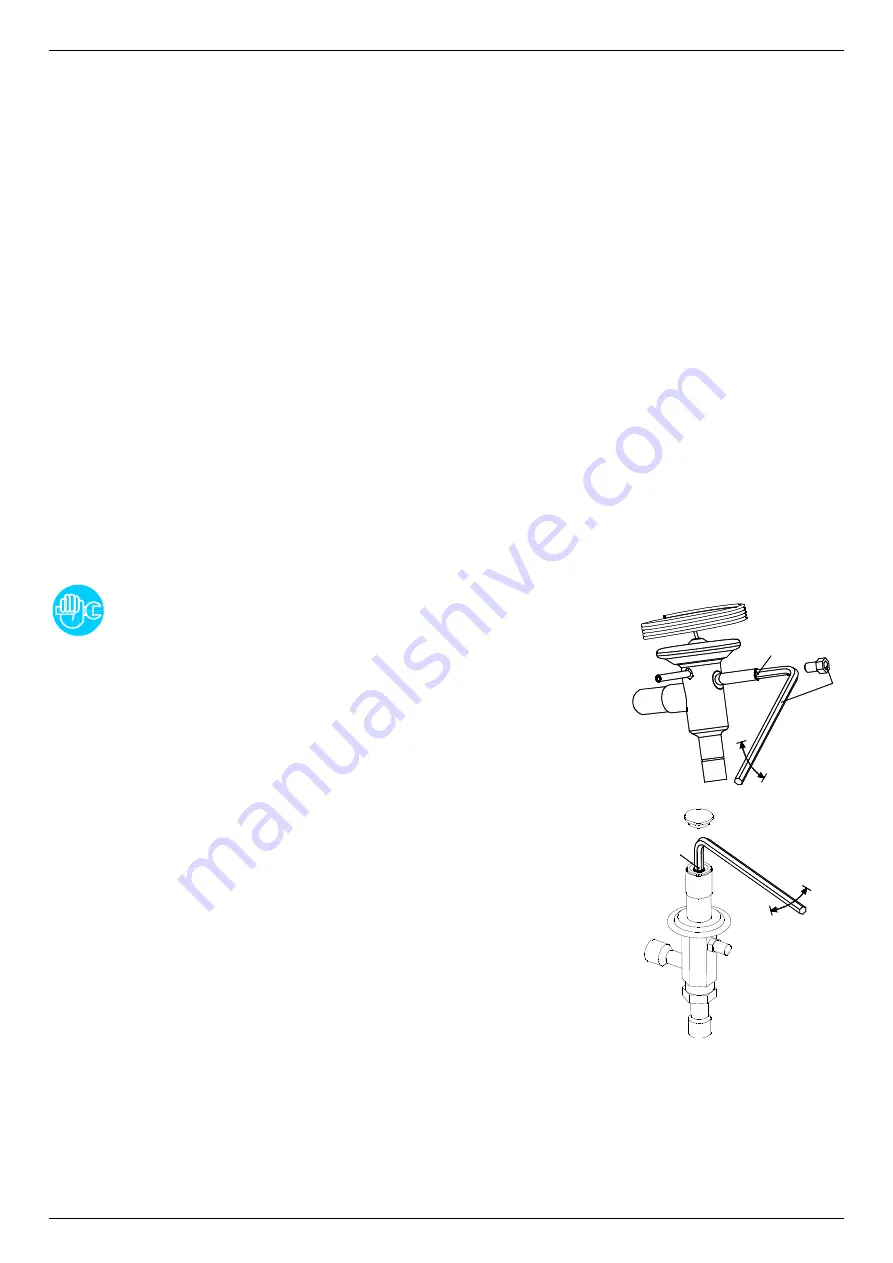

5.12. Hot Gas By-pass Valve

This valve injects part of the hot gas (taken from the discharge side of the compressor) in the pipe between the

evaporator and the suction side of the compressor, keeping the evaporation temperature/pressure constant at approx.

36°F (+2 °C). This injection prevents the formation of ice inside the dryer evaporator at every load condition.

DRYPOINT RA 200-1250 NA

A

4 mm

5/32 in.

+

-

V

L

Y

0

0

0

1

ADJUSTMENT

The Hot Gas By-pass Valve is adjusted during the manufacturing testing

phase. As a rule no adjustment is required; anyway if it is necessary the

operation must be carried out by an experienced refrigerating engineer.

WARNING!

the use of ¼” Schrader service valves must be justified by a real

malfunction of the refrigerating system. Each time a pressure gauge is

connected, a part of refrigerant is exhausted.

Without compressed air flow through the dryer, rotate the adjusting

screw (position A on the drawing) until the following value is reached:

Hot gas setting (R404A) :

temperature 33°F (+1 / - 0 °F)

pressure 75.4 psig (+1.5 / -0 psi)

temperature 0.5 °C (+0.5 / -0 °K)

pressure 5.2 barg (+0.1 / -0 bar)

DRYPOINT RA 1500-2500 NA

A

8 mm

5/16 in.

-

+

V

L

Y

0

0

0

3

Содержание DRYPOINT RA 1000/AC NA

Страница 37: ...List of attachments DRYPOINT RA 200 2500 NA 37 7 2 2 Exploded view DRYPOINT RA 200 350 NA ...

Страница 38: ...List of attachments 38 DRYPOINT RA 200 2500 NA 7 2 3 Exploded view DRYPOINT RA 400 500 NA ...

Страница 39: ...List of attachments DRYPOINT RA 200 2500 NA 39 7 2 4 Exploded view DRYPOINT RA 600 1250 NA ...

Страница 40: ...List of attachments 40 DRYPOINT RA 200 2500 NA 7 2 5 Exploded view DRYPOINT RA1500 2500 NA ...

Страница 51: ...List of attachments DRYPOINT RA 200 2500 NA 51 ...