8

5. INSTALLATION

5.1 Location

When installed in a panel enclosure complying with

the requirements for Ex n protection as shown in

section 3.2 of this manual, both indicators may be

located in a Zone 2 hazardous area providing that

the operating temperature is between –40°C and

+70°C and the installation complies with the

indicator's certification requirements. Certified

Ex e panel enclosures are frequently used as Ex n

panel enclosures.

The indicators may also be installed in an Ex e or

Ex p panel enclosure located in Zone 2 as

described in Appendix 1.

Both indicators have a stainless steel housings

with a 7J front of panel impact resistance

incorporating a 10mm thick toughened glass

window which can withstand a 4J impact. This,

together with a captive silicone gasket which seals

the joint between the instrument and the panel,

enclosure provides IP66 ingress protection. Both

indicators have IP20 rear protection.

Although the front of the indicators have IP66

protection, they should be shielded from

continuous direct sunlight and severe weather

conditions.

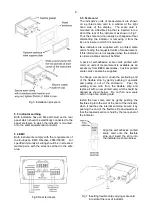

Fig 4 show the overall dimensions of the indicators

together with the recommended panel enclosure

cut-out dimensions.

Fig 4 Dimensions

5.2 Installation Procedure

a. Cut the aperture specified in Fig 4 in the

panel enclosure. Ensure that the edges of

aperture are de-burred.

b. Inspect the indicator's captive gasket and

ensure that it is not damaged before inserting

the indicator into the panel enclosure

aperture.

c. If the enclosure panel is less than 1.0mm

thick, or is non-metallic, an optional BEKA

stainless steel support plate should be slid

over the rear of the indicator before the panel

clamps are fitted to evenly distribute the

clamping force and prevent the enclosure

panel being distorted or creeping.

d. Slide a panel clamp into the two grooves at

each corner of the indicator housing with the

M3 stud protruding through the hole at the

rear of the clamp. Fit the stainless steel

spring washer over the stud and secure with

the stainless steel wing nut.

e. Evenly tighten the four clamps to secure the

instrument. The recommended minimum

tightening torque for each wing nut is 22cNm

(1.95 lbf in).

f.

Connect the panel enclosure wiring to the

rear terminal blocks. To simplify installation,

the terminals are removable so that wiring

can be completed before the instrument is

installed. Wiring should be supported to

prevent damage resulting from vibration.

g. Finally, fit a silicone rubber push-on cap to

the end of each M3 threaded rod.

Содержание BA307NE

Страница 1: ...Issue 3 1st Novemeber 2017 BA307NE BA327NE Ex nA Ex tc loop powered panel mounting indicators Issue 3...

Страница 10: ...10...

Страница 16: ...16...

Страница 22: ...22...