6

4. SYSTEM DESIGN FOR USE IN ZONE 2 GAS

HAZARDOUS AREAS.

4.1 Transmitter loops

When correctly mounted in Zone 2 both indicators

may be connected in series with almost any

4/20mA current loop with apparatus in the safe

area, or with Ex n, Ex e, Ex p or Ex d protected

apparatus located in Zones 1 or 2. The indicators

are transparent to HART

®

signals.

Because the BA307NE and BA327NE are not

certified intrinsically safe they should not be

connected to an intrinsically safe system.

There are four design requirements:

1. The indicator must be installed in a panel

enclosure complying with the requirements

for Ex n protection as shown in section 5 of

this manual.

2. The certificate specifies that the indicator

should be connected to a

limited energy

4/20mA circuit having a maximum output

current of 200mA. A

low voltage supply,

usually 24V, that is safe in normal operation

and suitable for live connection i.e. CE

marked, is usually considered acceptable.

3. Wiring must comply with Clause 9 of

BS EN 60079-14.

4. The loop must be able to tolerate the

additional 1.2V required to operate the

indicator. This increases to 5.0V if the

indicator is fitted with an optional backlight

which is loop powered. See 9.5.1

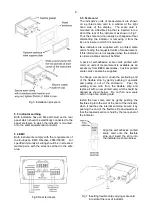

Figs 2 illustrate a typical application in which a

BA307NE or BA327NE located in Zone 2 is

connected in series with a 2-wire Ex d transmitter

located in Zone 1. BEKA Application Guide

AG310, which can be downloaded from

www.beka.co.uk, contains examples of other Ex n

applications.

Fig 2 Typical Zone 2 transmitter loop

To comply with the requirements of

BS EN 60079:

14:2008 Electrical installations

design, selection and erection

, each of the wires

entering the hazardous area should be individually

fused and contain a means of isolation. These two

requirements are frequently satisfied by using

switch fuse holders with easily removable fuses

which can be extracted to achieve isolation as

shown in Fig 20. This is a satisfactory method at

the low voltages and currents common in

instrumentation systems. Clear identification of,

and easy access to the means of isolation is

essential for their effective use. It is also necessary

to ensure that the maintenance procedure makes

sure that unauthorised re-closure of the switches

does not occur. It is not considered necessary to

have a means of isolation or electrical protection

for the screen.

For some applications Ex nA instrumentation

energised by a current limited power supply or

instrument that can be switched off, is often

considered adequate and to comply with the

requirements of the standard.

4.2 Remote indication

The BA307NE and the BA327NE may also be

driven directly from a safe area instrument with a

4/20mA output to provide a remote display within a

Zone 2 hazardous area.

There are four design requirements:

1. The indicator must be installed in a panel

enclosure complying with the requirements

for Ex n protection as shown in section 5 of

this manual.

2.

The certificates specify that the indicator

should be connected to a

limited energy

4/20mA circuit having a maximum output

current of 200mA. An instrument located in

the safe area that is safe in normal operation

and has a 4/20mA output suitable for live

connection i.e. CE marked, is usually

considered acceptable.

3. Wiring must comply with Clause 9 of

BS EN 60079-14:2008.

4. The output from the safe area 4/20mA

instrument must be able to supply the 1.2V

required to operate the indicator. This

increases to 5.0V if the indicator includes an

optional backlight which is loop powered.

See 9.4.1

Fig 3 shows a typical application.

Содержание BA307NE

Страница 1: ...Issue 3 1st Novemeber 2017 BA307NE BA327NE Ex nA Ex tc loop powered panel mounting indicators Issue 3...

Страница 10: ...10...

Страница 16: ...16...

Страница 22: ...22...