BARTINGTON INSTRUMENTS

Page 7 of 9

OM2497/4

6. Troubleshooting

The sensor is unlikely to suffer any defects in normal use: no internal components are

serviceable. The most likely causes of failure, and their solutions, are detailed in the following

table.

In the event of any apparent malfunction beyond those described in the table below, please email

, or telephone the Bartington Instruments service team on +44 (0)1993

706565.

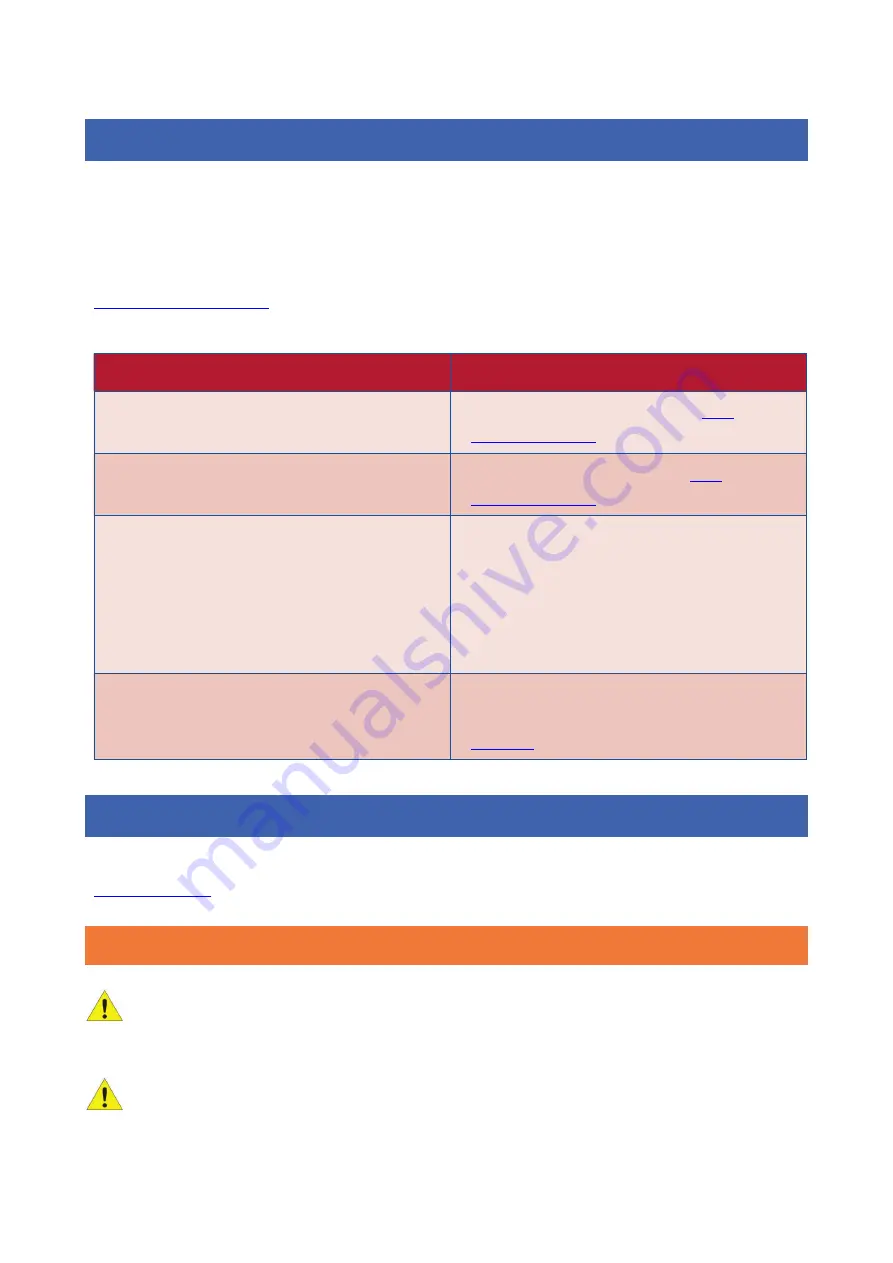

Causes of Failure

Solution

Power supply failure

Check the power, as detailed in

Cables

Test the cables, as detailed in

Power input

If no fault can be found in the power supply

or cables, ensure the cable length is not

too long, causing excessive voltage drop

between the power supply and sensor.

Refer to the specifications defined in the

product brochure.

Sensor damage

Physical damage to the Mag670 cannot

be repaired. Replace with a new unit. See

.

7. Care and Maintenance

No servicing is normally required. No repair is possible. For further details refer to

.

7.1. Cleaning Mag670 Sensors

Caution:

To clean an unenclosed variant of the Mag670, use an air duster to blow out

dust and debris if required. Use appropriate personal protective equipment, such as eye

protection, when carrying out this task.

Caution:

Avoid using chemicals, such as solvents, when cleaning the Mag670. Use a damp

cloth to remove grime from enclosures (packaged version only).