10

Service

Ÿ

Mount hubs on the shaft, leaving

the faces flush with the shaft ends.

Ÿ

Tighten the set screws if the model

has them.

Ÿ

Determine the required clearance

using Table 3. Using a spacer bar

with the obtained thickness, insert

between the hubs at the the same

depth and in 90 ° intervals.

Ÿ

Use a feeler gauge to measure the

gap between the space bar and

hub face. The difference between

the maximum and minimum must

not exceed the specified angular

limit.

Ÿ

Check that the pump-motor

alignment is correct, resting one

square object straight (ruler) at 90°

intervals. Check the clearance with

a feeler gauge.

Ÿ

Proceed to tighten the anchor and

check alignment and clearance

again; if necessary, repeat the

process from the beginning until

you get a proper alignment.

Ÿ

Insert the joint by the clearance

between the hubs and rest it on

any of the covers. Lubricate the

slots and clearance with as much

grease as possible.

Ÿ

Fill the spaces between the grid

and around it with grease. Remove

excess.

Ÿ

Oil the seals to slide on the hubs,

align and assemble the covers,

leaving a displacement of 180 °

between the lubrication holes.

Ÿ

Tighten the screws of the covers

and check for proper assembly of

the seals.

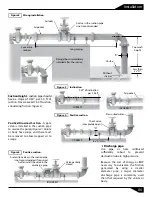

Socket head

set screw

Coupling

hubs

Rubber

spider

Figure 9

"Lovejoy" coupling.

Ÿ

To insert the grid, note that their

segments are radial. To extend as

little as possible, go partially

inserting segments using a soft

mallet. Once the segments are in

position, push them to the bottom

of the grids.

The grid the inner faces (INT) and

external (EXT) are marked for easy

identification.

Ÿ

Fit the covers with the seals (lightly

greased) on the shaft.

1

6

2

3

4

5

Figure 10 "Steelflex" type F coupling.

1 - Screws, nuts and washers

2 - Cover halves

3 - Gear hubs

4 - Grid members

5 - Gasket

6 - Seal rings

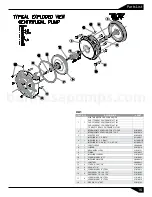

barmesapumps.com