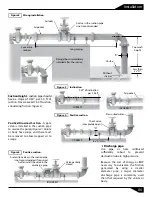

1 - Ceramic seat

2 - Seal seat Buna-N

3 - Inox. retainer

4 - Inox. jacket

5 - Inox. spring

6 - Carbon ring

7 - Elastomer Buna-N

8 - Inox. washer

2

1

3

6

4

5

7

8

Figure 7

Mechanical Seal - Sectional View.

Intermediate

coupling

Shaft

sleeve

Shaft

Seal

stationary

Seal

rotating

member

Seal

spring

Impeller

Impeller

lockwasher

Lockwasher Hex.

screw

Figure 8

Mechanical Seal - Assembly.

09

Service

Step 1: Install the intermediate

coupling if it was previously

removed. Make sure the shaft and

cavities, where will it seats, are clean.

The shaft sleeve should not be sharp,

but a radius of about 1/32”. It is

recommended that lightly polish the

area of the shaft. If the shaft and it

radius are perfectly polished, the seal

can be relatively easily installed.

Step 2: Install the seat assembly (1

and 2) on the inside of the

intermediate coupling, using an SAE

No. 90 oil in rubber parts. This

assembly should be done only

manually, meaning without the use

of an instrument.

Step 3: Install the rotating portion of

the seal without the spring. Lubricate

the shaft and the inside of the seal

with three or four drops of SAE No. 10

oil. With clean, dry hands, insert the

rotating portion to the shaft, sliding

it abuts the stationary seat. Once the

seal is in place, insert the spring (5).

Step 4: Place the impeller and

washers; tighten the hex screw.

Maintenance

Flexible Coupling -

Universal type

pumps generally use 2 different types

of flexible couplings: the "Lovejoy"

type with rubber spider, and the

"Steelflex" type "F" with grids buffer.

The first mentioned coupling requires

no lubrication, the second does

require lubrication at least every

twelve months. If the second type of

coupling is exposed to excessive

moisture, extreme temperatures,

sudden loads applications, etc., it

should be lubricated more often. For

more information on the type of

lubricant consult your distributor.

Flexible Coupling

"Lovejoy" type -

To remove, just

loosen the set screws on the hub. To

reinstall, align the shaft and tighten

the set screws. Should take in

consideration a clearance of 1/16"

(1.574 mm) between jaws. As

mentioned earlier, a good alignment

is essential for optimal operation.

"Steelflex" type -

Identify the parts

in Figure 10. The most relevant issue

in the assembly of a coupling of this

type is the clearance point that

should be left between the hubs; to

determine this see Table 3.

Disassembly

Flexible Coupling

Ÿ

Separate

coupling

covers,

removing the nuts and bolts. Be

sure not to damage the seal.

Ÿ

To remove the grid, use a round

bar or a screwdriver to fit the

curves of the grid.

Ÿ

Insert the tool into the open end of

the grid toward the curved end,

pry out gradually. Alternate

procedure on each side to pop out

half of the grating.

Ÿ

Repeat for each side until it clears

the grid.

Ÿ

If you need to remove the hubs,

loosen the set screws if the model

has them.

Assembly

Flexible Coupling

Ÿ

If the hubs are removed, adjust

shaft shims.

barmesapumps.com