8.8.1 Interlock Guarding Requirements

The following general requirements and considerations apply to the installation of interlocked gates and guards for the

purpose of safeguarding. Refer to the relevant regulations to be sure to comply with all necessary requirements.

Hazards guarded by the interlocked guard must be prevented from operating until the guard is closed. A Stop command

must be issued to the guarded machine if the guard opens while the hazard is present. Closing the guard must not, by itself,

initiate hazardous motion; a separate procedure must be required to initiate the motion. The safety switches must not be

used as a mechanical or end-of-travel stop.

The guard must be located at an adequate distance from the danger zone (so the hazard has time to stop before the guard

is opened sufficiently to provide access to the hazard), and it must open either laterally or away from the hazard, not into

the safeguarded area. Depending on the application, an interlocked gate or door should not be able to close by itself and

activate the interlocking circuitry. In addition, the installation must prevent personnel from reaching over, under, around, or

through the guard to the hazard. Any openings in the guard must not allow access to the hazard (see ANSI B11.19 or the

appropriate standard). The guard must be strong enough and designed to protect personnel and contain hazards within the

guarded area, which may be ejected, dropped, or emitted by the machine.

The safety switches and actuators used with the cascaded system must be designed and installed so that they cannot be

easily defeated. They must be mounted securely, so that their physical position cannot shift, using reliable fasteners that

require a tool to remove. Mounting slots in the housings are for initial adjustment only; final mounting holes must be used

for permanent location.

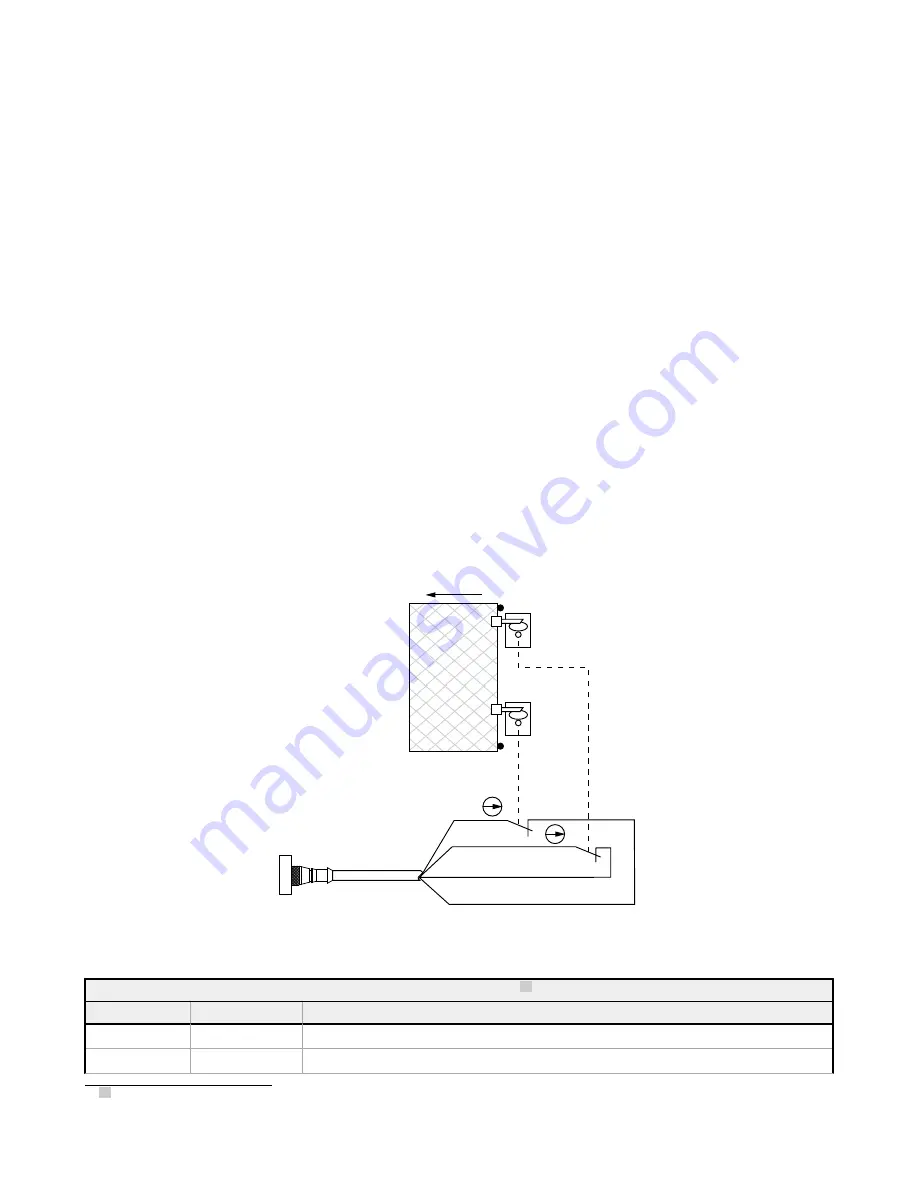

8.8.2 Positive-Opening Interlocking Safety Switches

Two individually mounted safety interlock switches are recommended for each guard to meet safety category 4, per ISO

13849-1, and must satisfy several requirements. Each switch must provide at minimum, one normally closed (N/C)

electrically isolated contact to interface with the Cascade input.

The contacts must be of positive-opening design, with one or more normally closed contacts rated for safety. Positive-

opening operation causes the switch to be forced open, without the use of springs, when the switch actuator is disengaged

or moved from its home position. Mount the switches to move/disengage the actuator from its home position and open the

normally closed contact when the guard opens.

bn

wh

bu

bk

22 awg

Open

Figure 30. Monitoring two positive-opening interlocking safety switches

This application is considered to meet or exceed requirements for OSHA control reliability and safety categories 4 per ISO

13849-1.

QDE2R4-8..D Cable Pinout 17

Pin

Color

Description

1

brown (bn)

Ch 1a

2

black (bk)

Ch 1b

17 Standard 8-pin M12/Euro-style QD cordsets can also be used, although the pin numbers and wire colors must be verified.

EZ-SCREEN

®

14/30 mm Safety Light Screen

74

www.bannerengineering.com - Tel: + 1 888 373 6767