• Sensor input or output wires routed too close to noisy wiring

9.4.1 Check for Sources of Electrical Noise

It is important that the light screen sensors have a good earth ground. Without this, the System can act like an antenna and

random Trips and Lockouts can occur.

All EZ-SCREEN wiring is low voltage; running these wires alongside power wires, motor/servo wires, or other high-voltage

wiring can inject noise into the EZ-SCREEN System. It is good wiring practice (and may be required by code) to isolate EZ-

SCREEN wires from high-voltage wires.

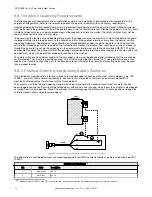

1. Use the Banner model BT-1 Beam Tracker Alignment Aid to detect electrical transient spikes and surges.

2. Cover the lens of the BT-1 with electrical tape to block optical light from entering the receiver lens.

3. Press the RCV button on the BT-1 and position the Beam Tracker on the wires going to the EZ-SCREEN or any

other nearby wires.

4. Install proper transient suppression across the load to reduce the noise.

9.4.2 Check for Sources of Optical Noise

1. Turn off the emitter, completely block the emitter, or open the Test input.

2. Use a Banner BT-1 Beam Tracker (see

on page 88) to check for light at the receiver.

3. Press the RCV button on the BT-1 and move it across the full length of the receiver’s sensing window. If the BT-1’s

indicator lights, check for emitted light from other sources (other safety light screens, grids or points, or standard

photoelectric sensors).

EZ-SCREEN

®

14/30 mm Safety Light Screen

www.bannerengineering.com - Tel: + 1 888 373 6767

81