U.S. Applications

European Applications

Ds

the Safety Distance, in inches

K

1600 mm per second (or 63 in per second), the OSHA

29CFR1910.217, and ANSI B11.19 recommended hand-speed

constant (see Note 1 below)

Ts

the overall stop time of the machine (in seconds) from the initial

stop signal to the final ceasing of all motion, including stop times

of all relevant control elements (for example, IM-T-.. Interface

Modules) and measured at maximum machine velocity (see Note 3

below)

Tr

the maximum response time, in seconds, of the EZ-SCREEN

emitter/receiver pair (depending on model)

Dpf

the added distance due to the depth penetration factor as

prescribed in OSHA 29CFR1910.217, and ANSI B11.19 for U.S.

applications. See Depth Penetration Factor (Dpf) table below or

calculate using the formula (in mm): Dpf = 3.4 × (S - 7) where S is

the resolution of the light curtain (for S ≤ 63 mm).

S

the Minimum Distance, in mm, from danger zone to light screen

center line; minimum allowable distance is 100 mm ( 175 mm for

non-industrial applications), regardless of calculated value

K

hand-speed constant (see Note 2 below); 2000 mm/s (for Minimum

Distances < 500 mm) 1600 mm/s (for Minimum Distances > 500

mm)

T

the overall machine stopping response time (in seconds), from the

physical initiation of the safety device and the machine coming to

a stop (or the hazard removed). This can be broken down into two

parts: Ts and Tr where T = Ts + Tr

C

the additional distance, in mm, based on intrusion of a hand or

object towards the danger zone prior to actuation of a safety

device. Calculate using the formula (in mm):

C = 8 × (d - 14)

where

d

is the resolution of the light curtain (for

d

≤ 40 mm).

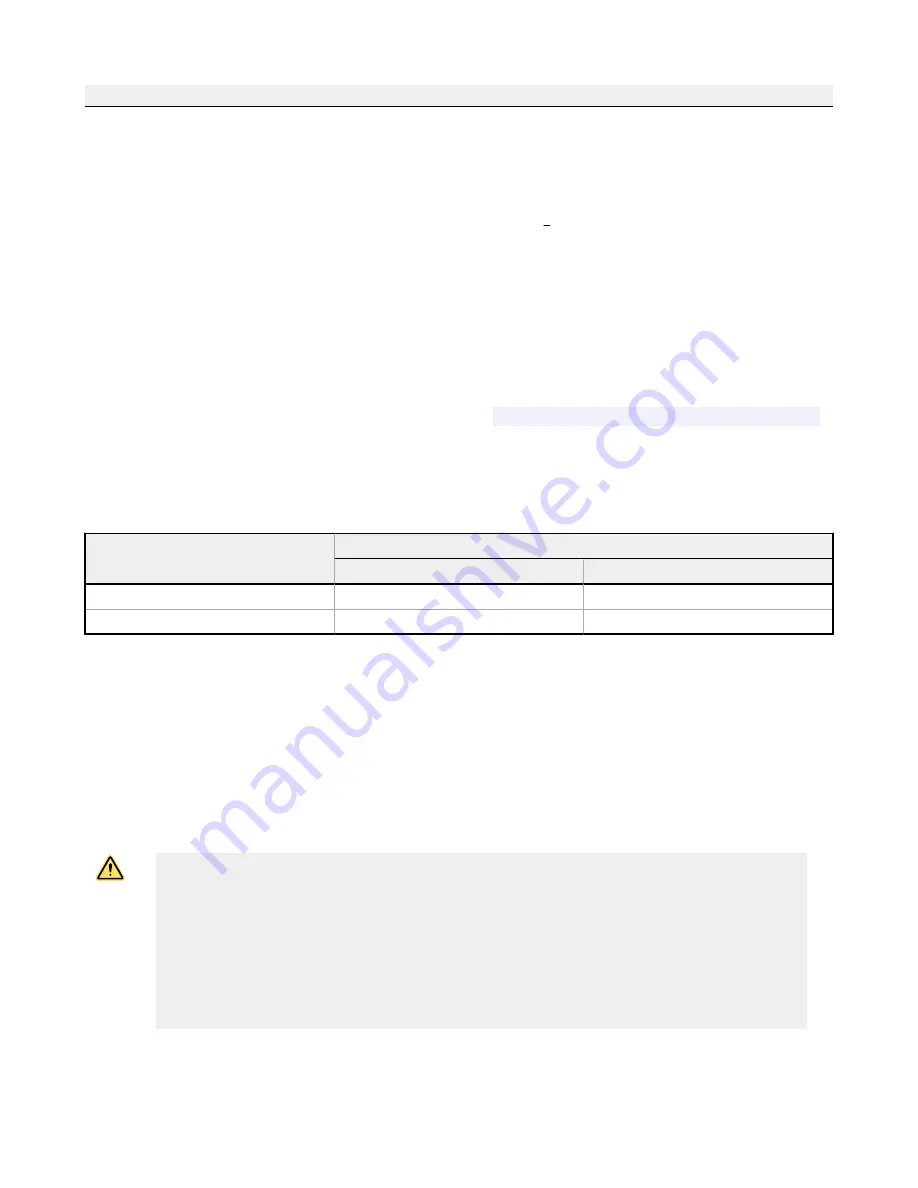

Table 1: Depth Penetration Factor (Dpf)

Reduced Resolution

Depth Penetration Factor (Dpf)

14 mm Systems

30 mm Systems

OFF

24 mm (1 in)

78 mm (3 in)

ON

78 mm (3 in)

180 mm (7 in)

Notes:

1. The OSHA-recommended hand speed constant K has been determined by various studies and, although

these studies indicate speeds of 1600 mm/sec. (63 in/sec.) to more than 2500 mm/sec. (100 in/sec.), they

are not conclusive determinations. Consider all factors, including the physical ability of the operator, when

determining the value of K to be used.

2. The recommended hand speed constant K, derived from data on approach speeds of the body or parts of

the body as stated in ISO 13855.

3. Ts is usually measured by a stop-time measuring device. If the machine manufacturer's specified stop time

is used, at least 20% should be added to allow for possible clutch/ brake system deterioration. This

measurement must take into account the slower of the two MPCE channels, and the response time of all

devices or controls that react to stop the machine.

WARNING:

• Stop time (Ts) must include the response time of all devices or controls that react to stop the

machine

• If all devices are not included, the calculated safety distance (Ds or S) will be too short, which can

lead to serious injury or death.

• Include the stop time of all relevant devices and controls in your calculations.

• If required, each of the two machine primary control elements (MPCE1 and MPCE2) must be

capable of immediately stopping the dangerous machine motion, regardless of the state of the

other. These two channels of machine control need not be identical, but the stop time

performance of the machine (Ts, used to calculate the safety distance) must take into account the

slower of the two channels.

EZ-SCREEN

®

14/30 mm Safety Light Screen

www.bannerengineering.com - Tel: + 1 888 373 6767

21