DESCRIPTION OF OPERATION WITH LIQUID

FUEL

FURTHER INSTRUCTIONS TO START A MIXED BURNER

It is not advisable to have too large a burner for the boiler for heating

and for hot water as the burner may work for long periods with a single

flame, making the boiler work at lower than required output; as a result

of this the combustion products (fumes) emerge at too low a tempe-

rature (at about 180°C in the case of heavy oil and 130°C with diesel

fuel), causing soot to build up at the chimney outlet.

IMPORTANT

When the boiler is working at lower output than that indicated by

the technicians, it is likely that acidic condensate and soot will

form in the boiler with the result that it will quickly corrode and

get clogged up.

When the two-flame burner is installed on a water boiler for heating

use, it must be connected so that it works normally with both flames,

completely stopping without passing to the first flame when the preset

temperature is reached.

To obtain this operating condition, do not install the second flame ther-

mostat and make a direct connection (bridge) between the respective

four pole plug terminals.

In this way, only the burner's capacity will be used for ignition at a

reduced flow rate for a soft start, which is an essential condition for

boilers with a pressurized combustion chamber, but also very useful for

normal boilers (vacuum combustion chamber). The burner's command

(on or off) is connected to the normal operating and safety thermostats.

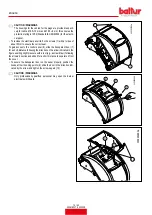

Closing the switch (1), if the thermostats are closed, the voltage (7)

reaches the command and control equipment (led 3 and 7 come on)

which starts the operating cycle. The fan motor and the ignition tran-

sformer are then switched on.

The motor turns the fan that carries out an air wash of the combustion

chamber and, at the same time, the fuel pump that causes circulation

in the ducts, expelling any gas bubbles through the return valve. This

pre-washing phase ends with the opening of the operating solenoid

valves that makes it possible for the fuel to reach the nozzle and enter

the combustion chamber finely atomised.

As soon as the atomized fuel exits the nozzle, it is set on fire by the

spark present between the electrodes since the start of the motor.

During first stage ignition, the air gate is held in the adjusted position

on the special air/gas adjustment servomotor cam.

If the flame appears regularly, after the safety time foreseen by the

equipment, it starts the air regulation servomotor that moves to the

2nd stage position. During the transition from the first to the second

stage, the equipment activates the solenoid valve (normally closed) of

the second stage.

The opening of the second stage valve allows the diesel to reach the

second nozzle and the burner to operate at full capacity.

From the time the flame appears in the combustion chamber, the bur-

ner is controlled by the photoelectric cell and thermostats.

The control equipment follows the program and switches the ignition

transformer off. When the temperature or the pressure in the boiler

reaches that set by the thermostat or pressure switch, the latter stops

the burner.

Subsequently, if the temperature of pressure decreases below the

lower thermostat or pressure switch threshold value, the burner will

switch on again.

If, for any reason, the flame is lost during burner operation, after just

one second the flame control device cuts off the power supply from the

relay, switching off the solenoid valves which intercept the fuel flow to

nozzles.

The equipment will shut-down automatically.

ENGLISH

19 / 42

0006160079_202008

Содержание 56510010

Страница 2: ......

Страница 42: ...SCHEMI ELETTRICI ITALIANO 40 42 0006160079_202008...

Страница 44: ...ITALIANO 42 42 0006160079_202008...

Страница 84: ...WIRING DIAGRAMS ENGLISH 40 42 0006160079_202008...

Страница 86: ...ENGLISH 42 42 0006160079_202008...

Страница 87: ......