BTL5-S1_ _-M_ _ _ _-P-S32/S147/KA_ _

Micropulse Linear Transducer in Profile Housing

3

english

2.1

Characteristics

Micropulse transducers feature:

–

High data security: Output data

are checked for validity and plau-

sibility in the µC

–

Very high resolution, repeatability

and linearity

–

Measurement range monitoring

with "Out of Range" Bit 2

21

–

Immunity to shock, vibration, and

contamination

–

An absolute output signal

–

Wear- and maintenance-free

–

BTL to processor cable lengths

up to 400 m

–

IP 67 per IEC 60529

2.2

Function

The Micropulse transducer contains

a waveguide enclosed by an ex-

truded aluminum housing. A mag-

net attached to the moving mem-

ber of the machine is moved

across the top of the housing and

its position constantly updated.

The magnet defines the measured

position on the waveguide. An

internally generated INIT pulse

interacts with the magnetic field of

the magnet to generate a magneto-

strictive torsional wave in the

waveguide which propagates at

ultrasonic speed.

The torsional wave arriving at the

end of the waveguide is absorbed in

the damping zone. The wave arriv-

ing at the beginning of the wave-

guide creates an electrical signal in

the coil surrounding the waveguide.

The corresponding value is output

as synchronous serial data (SSI) via

the RS 485/422 interface. This

takes place with high precision

and repeatability within the mea-

suring range indicated as the

nominal stroke length.

On both ends of the nominal

stroke length is an area which pro-

vides an unreliable signal, but

which may be entered.

The electrical connection between

the transducer, the processor/con-

troller and the power supply is via a

cable, which is connected using a

female connector.

2

Function and Characteristics

Dimensions for installing the

Micropulse transducer and for the

magnets and control arm are found

on

➥

➥

➥

➥

➥

page 5.

2.3

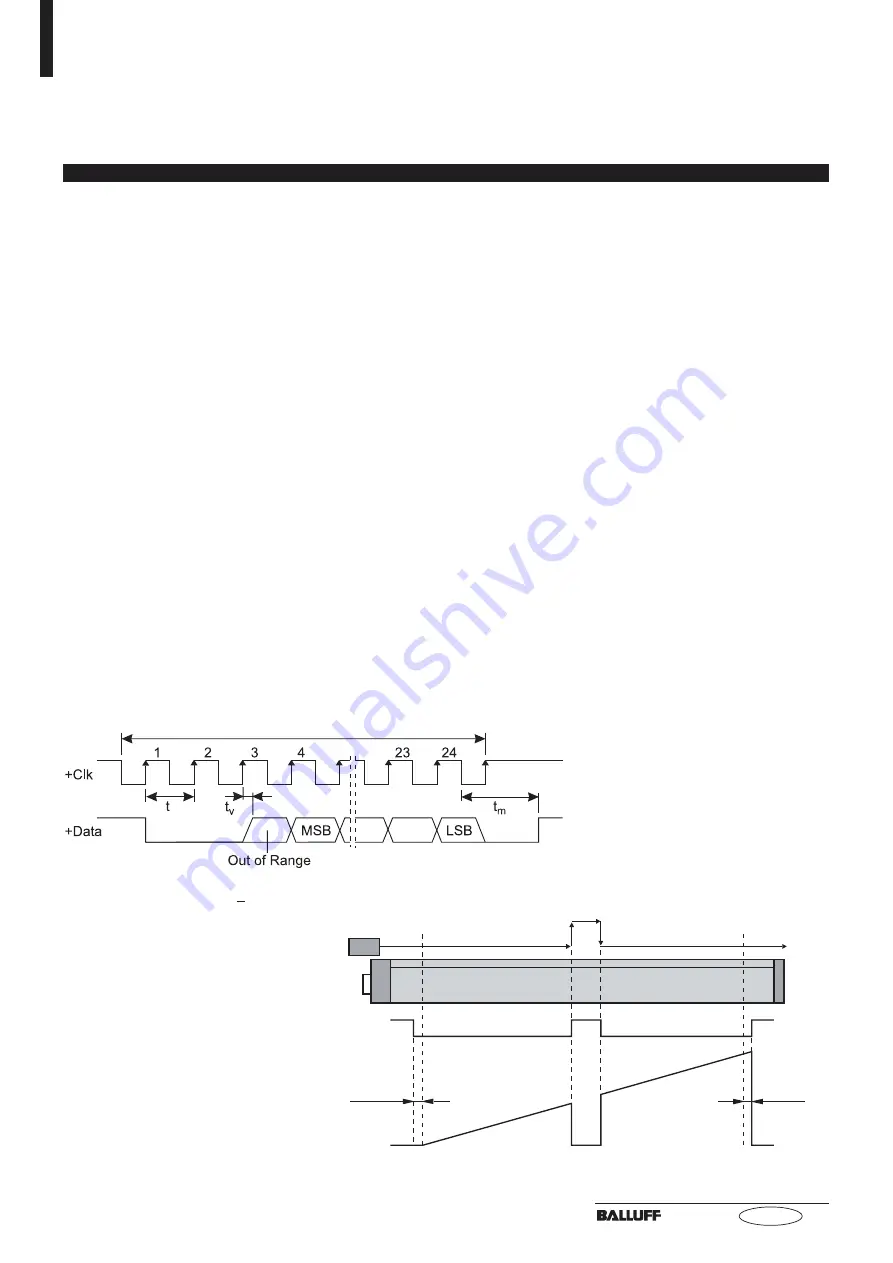

SSI interface

Depending on the BTL version, the

SSI interface uses 24 or 25 bits

and the position values are trans-

mitted in Gray or binary code.

Transmission of the position values

is finished in time t

m

. The max.

clock frequency t depends on the

cable length

➥

➥

➥

➥

➥

section 8 Technical

Data on page 9.

Bit 2

21

can be used as an "Out-of-

Range" message, see Figs. 2-1

and 2-2.

Sending of the position values is

finished within time t

m

. It is started

with the falling edge of the last

clock pulse. After this time the

BTL is ready for the next data

transmission.

Clock sequence

t < t

m

t

v

= 150 ns

measured with 1 m cable

t

m

= 31 µs

independent of the clock

frequency

The time tm starts with the falling edge of

the last clock impulse (bit 24 or bit 25

depending on the version).

Fig. 2-1: Pulse diagram, example with 24 bit coding

➀

only by an resolution of > 5 µm

Fig. 2-2: Output data shown with "Out of Range" situation

Position of magnet:

1) out of the measurement range

2) within the measurement range

3) magnet not present

"Out of Range" Bit 2

21

will be set

after the occurence of the event.

Value of the output data 2

0

... 2

20

:

1a) 0

1b) max. at end point + 10 mm

2) proportional to distance

3) 0

Technical data are valid within the

measurement range only, i.e. between

null and end point.

1a

2

3

2

1b

~10 mm

~10 mm

Bit 2

21

Bit 2

0

... 2

20

Null point

End point

➀