Instruction Manual

DCF-CO

101

Maintenance

• Operational Maintenance

PROBLEMS

PROBABLE CAUSES

SOLUTIONS

Product not

flowing to the

discs or

insufficient

amount.

The shut-off gate may be closed. Check and take them out in it is the case.

Foreign objects locking

the conveyor.

Assemble the cardan correctly

or replace crossheads with

excessive wear.

Conveyor, roller chain or

broken fuse.

Retighten the bearings or replace

them if damaged.

Wrong assembly of the gears.

Tension the conveyor belt.

Distribution of

the product in

the soil is not

uniform.

Distance between on stroke

and the other is too long.

Reduce distance between strockes

and operate according within the

recommended distance.

Fin in the wrong position on

power distribution discs.

Check the position of the fins if

they are not inverted according

to the rotating direction of the

distributor discs. If they are

inverted, proceed with their

correct assembly.

Rotating the power outlet.

Correct rotation in the PTO

which should be 540 RPM.

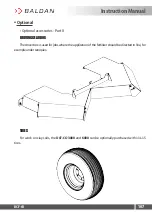

Very strong wind.

Wait until the wind reduces or

use the buffer (

optional

).

Distribution range

too narrow.

Position of fins on power

distribution discs.

Adjust the fins on the discs for

a more open position.

Recommended

dosage is not

obtained.

Dosage system.

Work speed above

recommendation.

Increase gate flow.

Reduce work speed.

Dosage

higher than

recommended.

Dosage system.

Work speed under

recomendation.

Reduce gate flow. Adjust work

speed to the recommended one.

Rompimento

do fusível com

frequência.

Belt operating over

recommended speed.

Foreign objects locking

the conveyor.

Reduce belt speed and

increase gate flow.

Check and clean the belt.

Содержание DCF-CO

Страница 1: ...Lime Fertilizer and Organic Fertilizer Spreader DCF CO...

Страница 2: ......

Страница 112: ...InstructionManual DCF CO 112 Notes...

Страница 113: ...InstructionManual DCF CO 113 Notes...

Страница 116: ......

Страница 118: ......

Страница 121: ......

Страница 122: ......