Masoneilan 35002 Series Camflex II Instruction Manual | 2

Copyright 2020 Baker Hughes Company. All rights reserved.

1. Introduction

The following instructions are designed to assist maintenance

personnel in performing most of the maintenance required on the

Camflex II valve and if followed carefully will reduce maintenance

time.

Baker Hughes has highly skilled Service Engineers available for

start-up, maintenance and repair of our valves and component

parts. In addition, regularly scheduled training programs are

conducted to train customer service and instrumentation

personnel in the operation, maintenance and application of our

control valves and instruments. Arrangements for these services

can be made through Baker Hughes products representative

or district office. When performing maintenance use only

Masoneilan replacement parts. Parts are obtainable through

your local representative or district office. When ordering parts

always include

MODEL

and

SERIAL NUMBER

of the unit

being repaired.

2. General

These installation and maintenance instructions apply to 1"

through 12" sizes (DN 25 through 300 sizes), all available

ratings, and pneumatic actuators. The model number, size and

rating of the valve are shown on the serial plate. Refer to Figure

1 to identify the valve model.

3. Principle of Operation

The concept of the Camflex II valve is based on an eccentrically

rotating spherical plug contained in a free flow body design. The

plug seating surface is joined by flexible arms to a hub which

slides onto a rotating shaft. The plug is free to center itself along

the axis of the shaft. A positive seal between plug and seat is

achieved by elastic deformation of the plug arms. The chamfered

seat ring is fixed in the valve body by a threaded retainer.

The plug and shaft are rotated through an angle of 50° by a lever

linked to a powerful spring-opposed rolling diaphragm actuator.

The solid disk-type handwheel and locking hex nut, optional, are

mounted on the yoke, opposite the actuator and may be used

to manually operate the valve or as a limit stop. A threaded hole

in the opposite side of the yoke is plugged but can be equipped

with an optional cap screw and locknut, which may be inserted

as a limit stop in the other direction, or in combination with the

handwheel to lock the valve in a selected position.

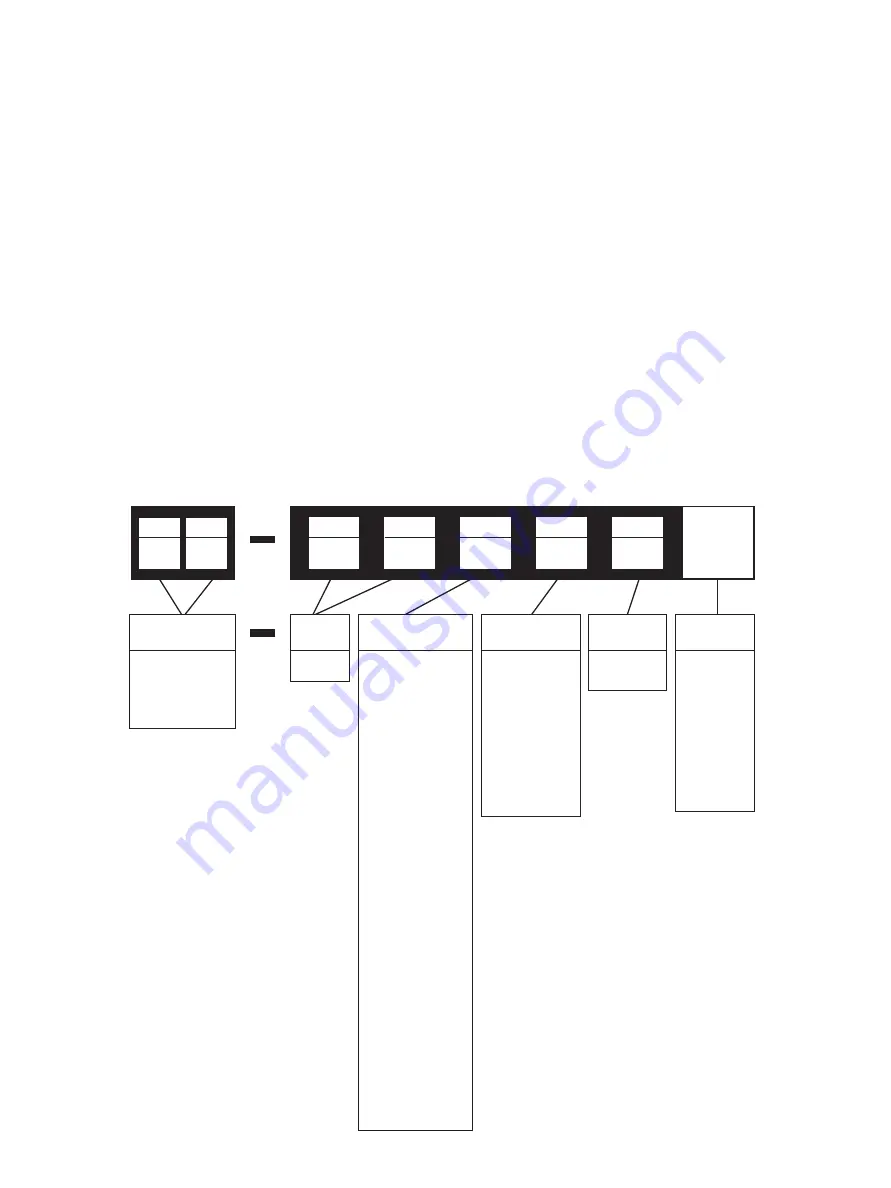

Figure 1

35002 Series Numbering System

Trim Type

Design

1st

2nd

Actuator Type

1. Parallel to

pipeline, valve

closes on stem

extension.

2. Parallel to

pipeline, valve

opens on stem

extension.

3. Perpendicular

to pipeline,

valve closes on

stem extension.

4. Perpendicular

to pipeline,

valve opens on

stem extension.

5. Parallel to

pipeline, valve

closes on stem

extension.

6. Parallel to

pipeline, valve

opens on stem

extension.

7. Perpendicular

to pipeline,

valve closes on

stem extension.

8. Perpendicular

to pipeline,

valve opens on

stem extension.

Actuator Mounting

(see guide on page 3)

Body

Series

35

SB

(optional

separable

bonnet)

GR

(optional

Globe

Replacement

face to face)

2

Design

Series

1. Metal Seat

2. Soft Seat

3. Metal Seat

w/ Differen

-

tial Velocity

Trim

4. Soft Seat w/

Differential

Velocity Trim

20 Manual Actuator

35 Spring-opposed

rolling-dia

-

phragm

4th

3rd

5th

2

2nd

5

1st

3