Masoneilan 35002 Series Camflex II Instruction Manual | 12

Copyright 2020 Baker Hughes Company. All rights reserved.

E.

Replace lever (34) on valve shaft (19) and tighten lever

capscrew (49).

F.

Using the lever (34) manually close the plug with sufficient

force to allow seat ring and plug to align.

G.

Using the seat ring wrench, tighten seat ring retainer to the

minimum torque value specified in Figure 12.

Note: In some cases, for the valves from 3" to 12" (DN 80

to 300) with metal seat, the alignment can be improved

by placing a piece of paper 0.10mm (0.004") thick and

approximately 6mm (1/4") wide at a point where the

leading edge and the trailing edge of the plug contacts

the seat ring and close the plug. With a slight pressure

on the lever, the paper strips should both be clamped in

place. For the valve 8" to 12" (DN 200 to 300), the piece

of paper shall be 0.20mm (0.008") thick and 12mm (1/4")

wide.

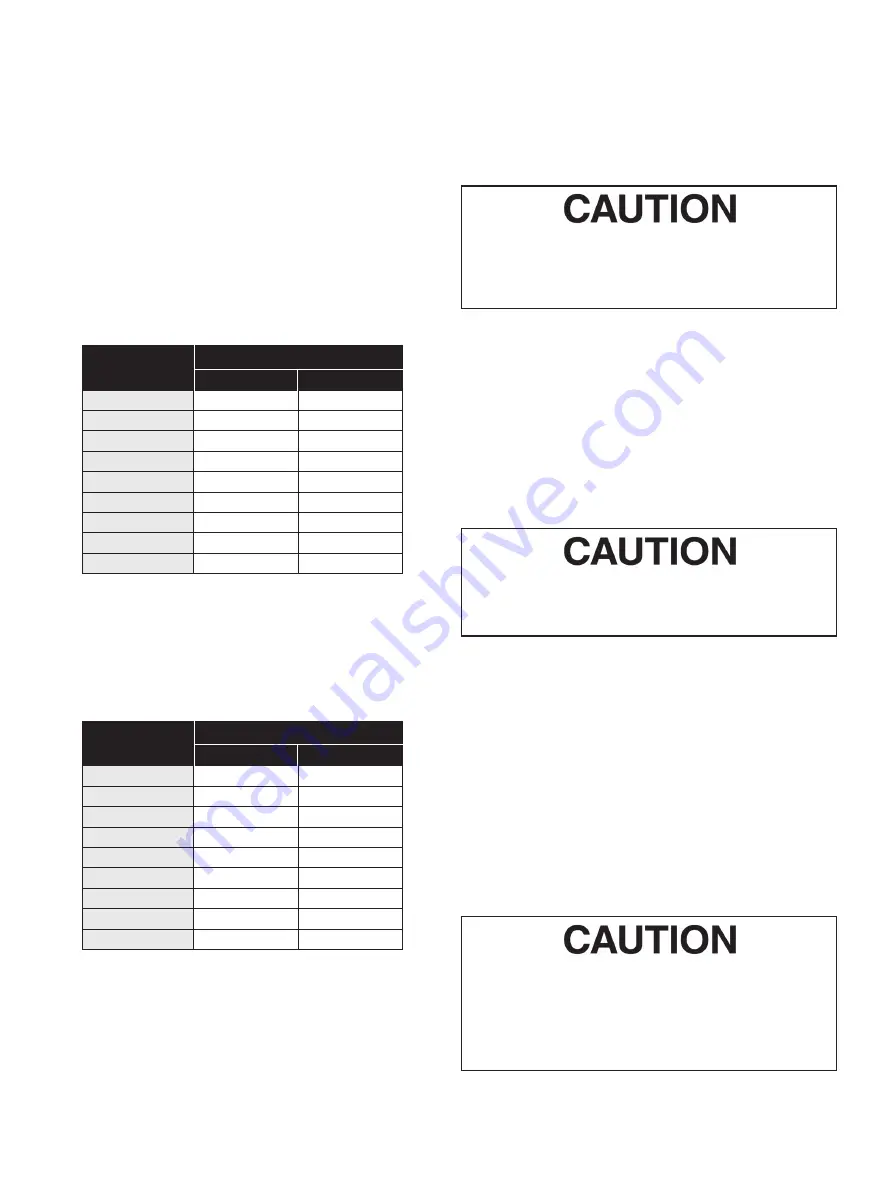

Valve Size

Minimum Torque

lb.ft

m.N

1" (DN 25)

60

81

1

1

⁄

2

" (DN 40)

95

130

2" (DN 50)

100

135

3" (DN 80)

290

395

4" (DN 100)

363

490

6" (DN 150)

825

1120

8" (DN 200)

975

1320

10" (DN 250)

1350

1830

12" (DN 300)

2250

3050

Figure 12

H.

Proceed to section on body to actuator assembly.

10.7 DVD Plate Reassembly

Using the same method and tooling as described in 8.3.2,

tighten the

Lo-dB™

plate at the indicated torque given in the

table of Figure 13.

Valve Size

Tightening Torque

lb.ft

m.N

1" (DN 25)

74

100

1

1

⁄

2

" (DN 40)

81

110

2" (DN 50)

100

135

3" (DN 80)

220

295

4" (DN 100)

363

490

6" (DN 150)

780

1050

8" (DN 200)

975

1320

10" (DN 250)

1320

1830

12" (DN 300)

2250

3050

Figure 13

11. Actuator Stem Adjustment

(Refer to Figures 16 and 17)

The following procedures must be adhered to in order to ensure

correct valve operation. Failure to do so could result in valve

damage and equipment malfunction.

Correct actuator stem adjustment is imperative for

proper valve functioning. With the actuator assem-

bled to the valve in the desired location and orienta-

tion proceed as follows:

Note: If any of the following steps were completed during

maintenance or reorientation of actuator to valve, proceed

to the next step.

A.

Remove front cover (32) and rear cover (29) by removing

the two-cover screws (30).

B.

Back off handwheel (53) so it does not interfere with the

operation of the lever (34).

C.

If applicable, back off optional limit stop (77) so it will not

interfere with the operation of the lever (34).

D.

Apply air pressure to the actuator and move lever (34) to an

intermediate position.

Do not exceed pressure listed in Figure 14 for the

actuator used. Do not use handwheel (53) to move

lever (34).

E.

Remove adjustable indicator (88) by removing the two

screws (89).

F.

Remove clevis pin clip (5), remove clevis pin (7).

G.

Relieve air pressure to the actuator to allow the clevis (35)

and lever (34) to separate.

Note: If the unit is air-to-open, separate clevis (35) and

lever (34) then loosen clevis locknut (46) and remove

clevis.

H.

Insert clevis pin (7) back in lever (34).

I.

Manually push the lever (34) so the valve is in the closed

position.

J.

Temporarily replace front cover (32) and check the location

of the clevis pin (7) in relation to the closed position indicator

mark on front cover (32).

The relationship must be as shown in Figure 18. If

it is not, the yoke must be separated from the body

and the lever (34) repositioned on the shaft. Refer to

appropriate section. Failure to comply could result in

the valve short stroking or over stroking and could

damage the valve.

Note: If the unit is air-to-open, replace clevis locknut