AV6A

7

DeviceNet Protocol “D”

The DeviceNet protocol provides a set of data bits inside a DeviceNet

message that represent the encoder position (in turns and within 1

turn).

DeviceNet may be wired in several different configurations, but the

most common is a “Trunk and Drop Line” configuration. The trunk

message cable must be terminated at each end with 120 ohm

resistors. Note that DeviceNet also offers the option to carry device

power to each encoder through an additional cable pair of wires.

Preferred cable: Nidec Avtron recommends structured DeviceNet

wiring systems, available from a broad range of vendors. Large

diameter main, small diameter round cable, as well as flat cabling

systems are all acceptable.

For more details on DeviceNet, consult the Open DeviceNet Vendor’s

Association (ODVA):

www.odva.org

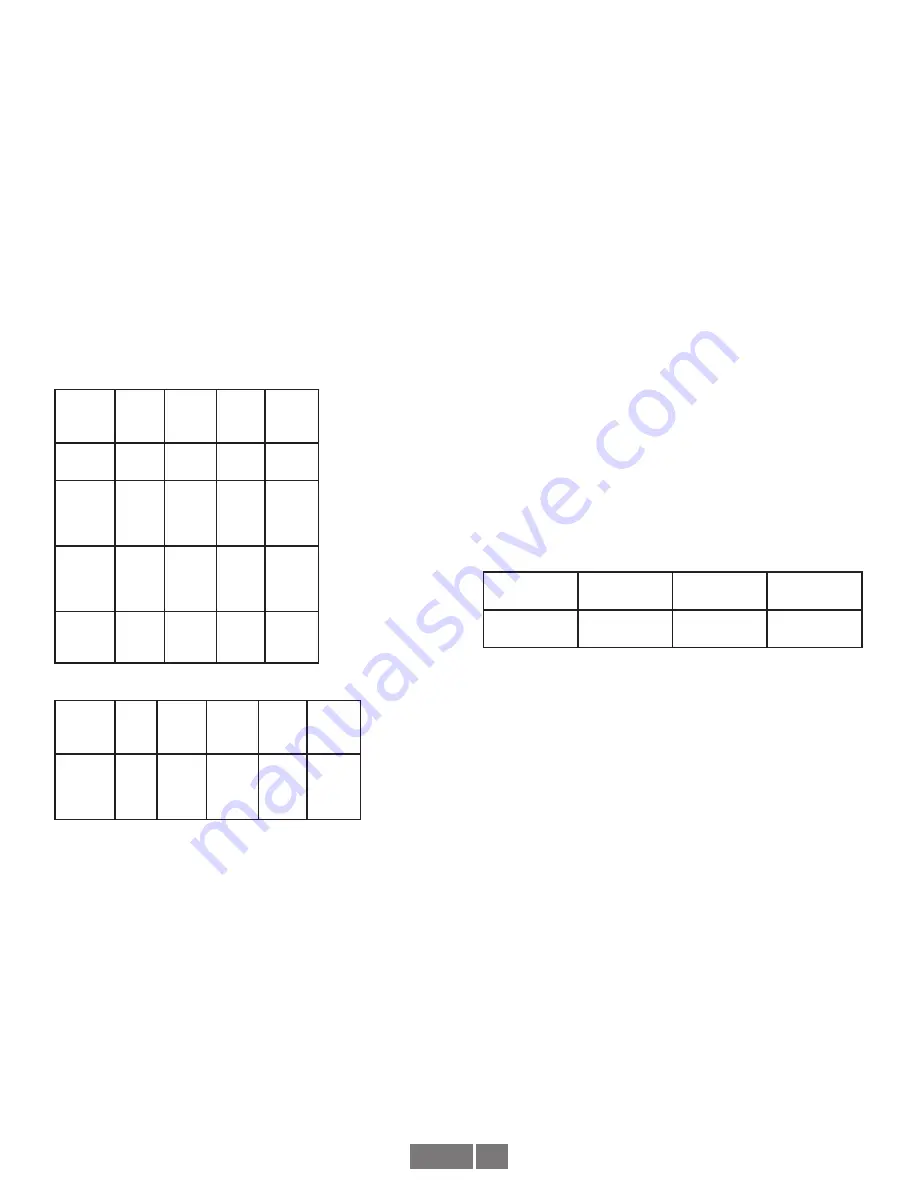

Network

Baud

Rate

500K

250K

125K Units

Max.

Length*

325

[100]

800

[250]

1600

[500]

ft

[m]

Max.

Single

Tap

Length

15

[5]

15

[5]

15

[5]

ft

[m]

Max.

Total

Tap

Length

100

[30]

200

[60]

400

[120]

ft

[m]

Min. Tap

to Tap

Length

20

[6]

20

[6]

20

[6]

ft

[m]

*Using thick cable

Number

of

Nodes

2

16

32

64

Units

Max.

Overall

Cable

Length*

750

[229]

690

[210]

640

[190]

560

[170]

ft

[m]

*Using thick cable

Setting Node (MAC-ID), Baud Rate & Termination Resistor

NOTE: Units with hardware connection caps cannot accept

software-commanded address, baud rate or termination resistor

changes. These must be made using the switches in the connection

cap. Before commencing any changes, check for a connection cap.

It is secured to the rear of the encoder with 2 or 3 screws and due

to snug fit will require a strong pull to remove it after removing the

screws.

NOTE: Any changes to baud rate, node number, or resistor will not

take effect until the encoder is reset (typically power cycled)--be

sure to store parameters in EEPROM.

NOTE: Baud rate, termination resistor and a values are not stored

permanently until they are written to EEPROM. If power is cycled

before the values are stored, the encoder will default to the values

previously stored in EEPROM.

Setting Node Number:

To set the node number on units with a connection cap: Set the

address using the two rotating switches. The node number can be

between 0-63. The node address = X10 switch * 10 + X1 switch

value.

To set the node MAC-ID number on units without a connection cap:

write attribute 6Fh (byte). [(master MAC-ID) 0x10 0x23 0x01 0x6F

(node)]. The encoder will reply [0x0A 0x90].

Setting Baud Rate:

To set the baud rate on units with a connection cap: Set the baud

rate using the rotating switch marked Bd per the table below.

To set the baud rate: write the baud code to attribute 6Eh (byte).

[(master MAC-ID) 0x10 0x23 0x01 0x6E (baud code)]. The encoder

will reply [0x0A 0x90].

Network Baud

Rate

500K

250K

125K

Baud Code/

Switch Setting

0x02

0x01

0x00

Enabling Termination Resistor:

To enable the termination resistor in units with a connection cap:

Turn switch Rt to “On”.

To enable the termination resistor: write 01 to attribute 67h. Ensure

any devices on the bus power up at least 700mS after the encoder

with the termination resistor activated.

Note that only devices at each end of the bus should have

termination resistors enabled--if the master/scanner is at one of the

bus, then only one encoder (at the opposite bus end) will require a

termination resistor.

Measuring Position, Speed, and Acceleration

Only position feedback is supported in DeviceNet; acceleration and

speed are not directly supported at this time.

To read position feedback into your device: Following the

instructions for your master/scanner module for the DeviceNet

network, load the encoder EDS file into your configuration. Assign it

to the correct MAC-ID node number. Store the configuration to the

scanner module.

All of the position data and other parameters will be read by

the scanner module and placed in registers identified in the

configuration package.

Setting Polling, Cyclic and Sync Mode

Polling, cycling and sync mode are supported by the encoder; use

the parameters supplied in the EDS file to set the appropriate mode.