EN-1320

OPERATION AND INSTALLATION MANUAL

12.10 MAINTENANCE PRACTICES

There are described maintenance practices in this section together for all governor models LUN7815 and

LUN7816, if no other note applied.

(1) Cleaning

DO NOT USE PRESSURE WASHING EQUIPMENT. PRESSURE WASHING CAN FORCE WATER

AND/OR CLEANING SOLVENTS INTO THE GOVERNOR, WHICH CAN LEAD TO CORROSION OF

INTERNAL COMPONENTS AND/OR INCORRECT FUNCTION.

DO NOT USE AN CAUSTIC OR ACIDIC SOLUTIONS TO CLEAN ANY PROPELLER PART.

BEFORE USING CLEANERS, MAKE SURE THAT THE CLEANER WILL HAVE NO NEGATIVE

EFFECTS ON METAL OR PAINTED SURFACES.

IF THE LUBRICATION IS INADVERTENTLY REMOVED FROM MOVING PARTS SUCH AS THE

PIN [52, FIG.12-38], CARBON BLOCK ASSEMBLY [22, FIG.12-38], ROD BEARINGS, ETC., DURING

THE CLEANING PROCESS, IT WILL BE NECESSARY TO RE-LUBRICATE THESE PARTS USING

AEROSHELL GREASE 5, 6 OR 22.

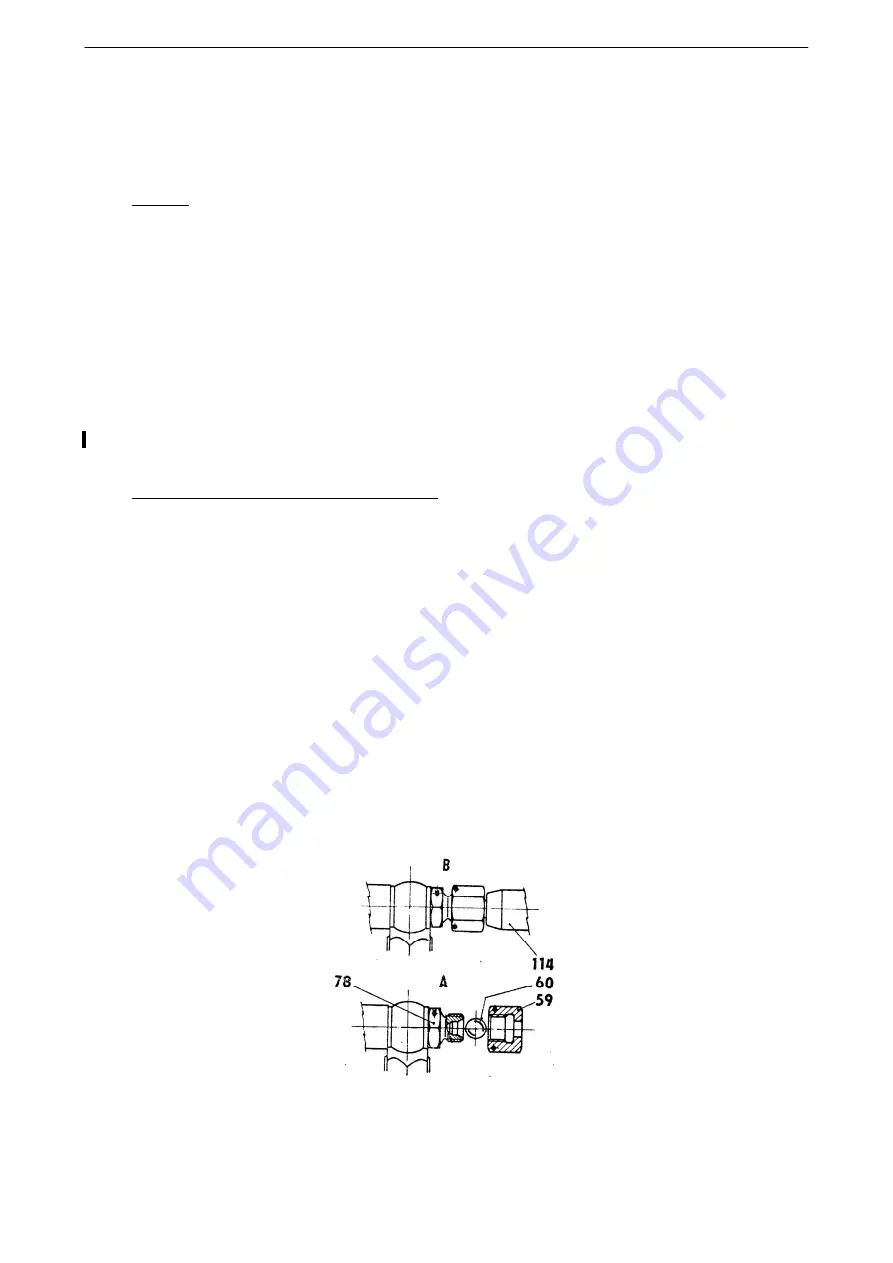

(2) Relief valve adjustment check - see figure 12-34

NOTE:

For governor LUN7816.(-) it concerns check of relief valve pressure for the valve No.1 (RV I).

Loose and unscrew the nut 59 with ball 60 from the turning screw 78. Connect measuring hose 114 with

manometer to the turning screw 78 and place it such way, that manometer sale is legible. Fix the hose to

don’t touch hot parts.

Start the engine according to the flight manual and warm-up oil to 60

°

+5

°

C (140 to 149°F). Place propeller

control lever to maximum RPM position. Move engine control lever to position, where propeller speed is

1950 to 2080 rpm. Read pressure.

Pressure for governor series LUN7816 should be in range 2,6 to 2,85 MPa (377 to 413 psi) if no other

adjustment is used for appropriate application. For the governor LUN7815.02, the pressures are in table

12-6.

Pressure adjustment is described in the following section.

After engine stop, remove the hose and reinstall the nut 59 with the ball 60 and secure. If necessary, clean

the governor.

Figure 12-34 Manometer connection

61-10-20

PROPELLER CONTROL SYSTEM

(Installation With Jihostroj LUN-Series Governor)

Page 12-37

2019-03-04